Planar transformers offer a compact, low-profile design with improved thermal management and higher efficiency compared to wire-wound transformers, making them ideal for high-frequency applications. Your choice depends on space constraints and performance needs, as wire-wound transformers provide robust handling of higher power levels and mechanical flexibility.

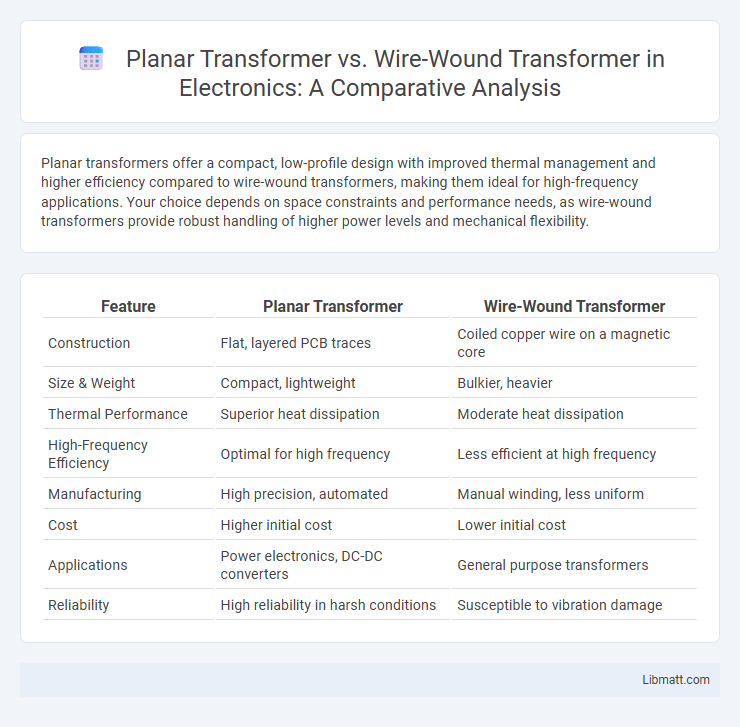

Table of Comparison

| Feature | Planar Transformer | Wire-Wound Transformer |

|---|---|---|

| Construction | Flat, layered PCB traces | Coiled copper wire on a magnetic core |

| Size & Weight | Compact, lightweight | Bulkier, heavier |

| Thermal Performance | Superior heat dissipation | Moderate heat dissipation |

| High-Frequency Efficiency | Optimal for high frequency | Less efficient at high frequency |

| Manufacturing | High precision, automated | Manual winding, less uniform |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Power electronics, DC-DC converters | General purpose transformers |

| Reliability | High reliability in harsh conditions | Susceptible to vibration damage |

Introduction to Planar and Wire-wound Transformers

Planar transformers use flat, printed circuit board windings, offering compact size, low profile, and improved thermal management compared to traditional wire-wound transformers, which consist of copper wire coils wrapped around a magnetic core. Wire-wound transformers provide robust construction, ease of customization, and cost efficiency for various power applications. Your choice between planar and wire-wound transformers depends on the application's space constraints, power density requirements, and thermal performance.

Core Construction Differences

Planar transformers feature a flat, layered core construction using thin magnetic laminations stacked horizontally, enabling compact size and efficient heat dissipation. Wire-wound transformers utilize traditional cylindrical or E-I cores with wire coils wrapped around the core, resulting in bulkier designs and increased parasitic inductances. Your choice impacts thermal management and electromagnetic performance based on these fundamental core construction differences.

Winding Techniques: Planar vs Wire-wound

Planar transformers utilize flat, printed circuit board windings that enable precise control of inductance and reduced parasitic capacitance, which enhances performance at high frequencies. Wire-wound transformers employ traditional copper wire coils wrapped around a magnetic core, offering robust magnetic coupling and higher power handling but with increased size and inductive losses. The planar winding technique provides compactness and thermal management advantages, while wire-wound remains preferred for applications demanding higher current capacity and mechanical durability.

Efficiency and Power Density Comparison

Planar transformers exhibit higher efficiency due to reduced parasitic inductance and lower AC losses compared to wire-wound transformers, which use bulkier windings. Their compact design enables significantly greater power density, making them ideal for applications requiring space-saving solutions and high-frequency operation. Wire-wound transformers, while robust, generally have lower power density and efficiency in high-frequency environments due to increased copper and core losses.

Thermal Management Capabilities

Planar transformers offer superior thermal management capabilities through their low-profile design and enhanced surface area, which allows for efficient heat dissipation compared to wire-wound transformers. Their compact construction facilitates integration with heat sinks and natural or forced convection cooling methods, reducing hotspot formation and improving reliability in high-frequency applications. Choosing planar transformers can optimize your system's thermal performance and extend component lifespan under demanding operational conditions.

Size and Weight Considerations

Planar transformers offer significant advantages in size and weight compared to wire-wound transformers due to their compact, low-profile design and integrated construction, which reduces the overall footprint. Wire-wound transformers tend to be bulkier and heavier because of their traditional coil winding and laminated core assembly. If minimizing the size and weight of your power supply or electronic device is critical, planar transformers provide an efficient solution without compromising performance.

Electrical Performance and Frequency Response

Planar transformers exhibit lower leakage inductance and reduced parasitic capacitance compared to wire-wound transformers, enhancing their electrical performance in high-frequency applications. Their flat, layered construction allows for superior frequency response, typically operating efficiently up to several MHz, whereas wire-wound transformers are often limited by increased losses and reduced efficiency at higher frequencies. Consequently, planar transformers are preferred in compact, high-frequency power supplies requiring minimal electromagnetic interference and improved thermal management.

Reliability and Longevity

Planar transformers offer enhanced reliability and longevity due to their compact design, reduced inter-winding capacitance, and superior thermal management compared to wire-wound transformers. Their flat coils and uniform heat distribution minimize hot spots, leading to less aging of insulation materials and longer operational life. Choosing a planar transformer can improve your system's durability and reduce maintenance costs over time.

Manufacturing Processes and Cost Implications

Planar transformers utilize printed circuit board (PCB) fabrication techniques, enabling automated mass production with high precision and reduced material waste compared to wire-wound transformers, which require labor-intensive winding processes and manual assembly. The planar design's compact and flat geometry simplifies integration into modern electronics, leading to lower overall manufacturing costs despite higher initial tooling expenses. Wire-wound transformers, while typically cheaper per unit in small quantities due to simpler materials, incur higher labor costs and longer production times, making planar transformers more cost-effective for high-volume, high-performance applications.

Application Suitability and Industry Usage

Planar transformers excel in high-frequency applications, such as telecommunications, aerospace, and compact power supplies, due to their low profile, efficient heat dissipation, and precise magnetic coupling. Wire-wound transformers are preferred in industrial settings requiring higher power handling, robustness, and cost-effectiveness, including motor drives and heavy-duty power equipment. Your choice depends on application demands for size, frequency, power rating, and regulatory compliance.

Planar transformer vs Wire-wound transformer Infographic

libmatt.com

libmatt.com