An H-bridge circuit allows control of a motor's direction by switching current through four transistors, providing full bidirectional control and greater power handling. A half-bridge uses two transistors to control power delivery in one direction, making it simpler but less versatile than an H-bridge for your motor control needs.

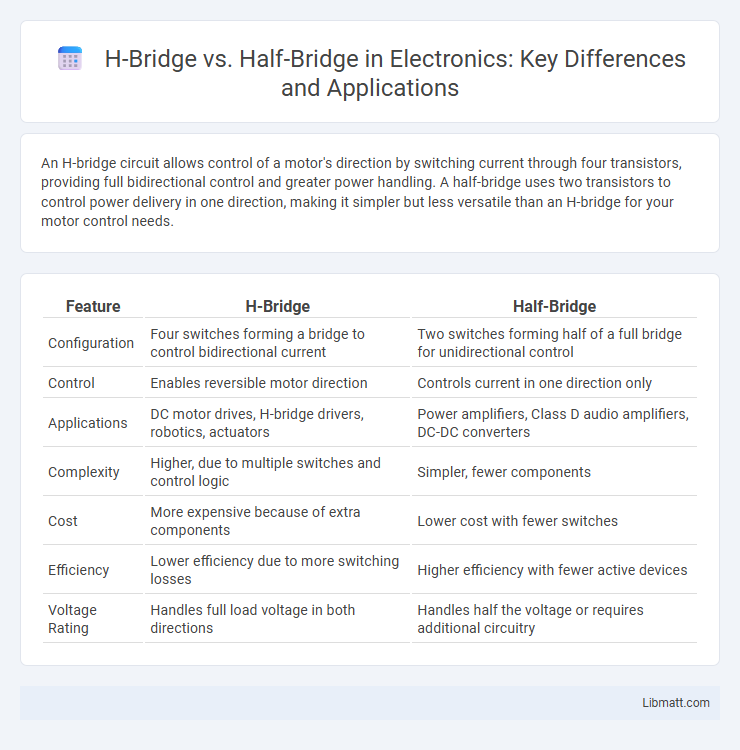

Table of Comparison

| Feature | H-Bridge | Half-Bridge |

|---|---|---|

| Configuration | Four switches forming a bridge to control bidirectional current | Two switches forming half of a full bridge for unidirectional control |

| Control | Enables reversible motor direction | Controls current in one direction only |

| Applications | DC motor drives, H-bridge drivers, robotics, actuators | Power amplifiers, Class D audio amplifiers, DC-DC converters |

| Complexity | Higher, due to multiple switches and control logic | Simpler, fewer components |

| Cost | More expensive because of extra components | Lower cost with fewer switches |

| Efficiency | Lower efficiency due to more switching losses | Higher efficiency with fewer active devices |

| Voltage Rating | Handles full load voltage in both directions | Handles half the voltage or requires additional circuitry |

Understanding H-Bridge and Half-Bridge Topologies

H-bridge and half-bridge topologies are essential for controlling the direction and power of DC motors and other loads. An H-bridge consists of four switches arranged in an "H" configuration, allowing full bidirectional control and enabling your motor to run forward, reverse, brake, or coast. Half-bridge topology uses two switches and a midpoint capacitor, providing efficient power conversion and control primarily in power electronics and inverter circuits.

Key Differences Between H-Bridge and Half-Bridge

H-bridge circuits enable bipolar voltage output by allowing current to flow in both directions through a load, making them ideal for controlling DC motors with reversible rotation. Half-bridge configurations use two switches and provide unipolar output voltage relative to a common reference, suitable for single-ended power applications like motor drivers and DC-DC converters. The main difference lies in their switching topology and voltage polarity capabilities, where H-bridges offer full bidirectional control, while half-bridges provide simpler, cost-effective power conversion with limited directional control.

Principle of Operation: H-Bridge vs Half-Bridge

An H-Bridge operates by using four switching elements arranged in an "H" pattern to allow current flow in either direction through a load, enabling full control of motor direction and speed. The Half-Bridge topology consists of two switches and typically controls power in a single direction with a complementary switching scheme, often used in DC-DC converters and amplifier circuits. H-Bridges provide bidirectional control ideal for DC motors, while Half-Bridges offer simpler, unidirectional power regulation with efficient switching.

Applications of H-Bridge Circuits

H-bridge circuits are widely used in applications requiring bidirectional control of DC motors, such as robotics, electric vehicles, and industrial automation. Their ability to reverse motor polarity enables precise speed and direction management, making them essential for motor driver boards and embedded systems. Your projects involving motor control will benefit from the versatility and efficiency of H-bridge configurations.

Uses of Half-Bridge Circuits

Half-bridge circuits are widely used in DC-DC converters, motor drives, and power amplifiers due to their efficiency in voltage regulation and power switching. These circuits provide a cost-effective solution for driving inductive loads with moderate power levels, commonly found in industrial automation and electric vehicle applications. Half-bridge configurations enable smooth control of AC signals and enable energy recovery in regenerative braking systems.

Efficiency Comparison: H-Bridge vs Half-Bridge

H-bridge circuits typically offer higher efficiency in bidirectional motor control by minimizing power losses during switching and allowing effective energy regeneration compared to half-bridge configurations. Half-bridge designs, while simpler and cost-effective for unidirectional loads, exhibit increased conduction and switching losses under certain load conditions, reducing overall efficiency. Optimizing your system requires evaluating the load demands and switching frequencies to choose between the superior energy conservation of an H-bridge and the simplicity of a half-bridge.

Cost Analysis: H-Bridge versus Half-Bridge

H-Bridge circuits generally incur higher costs due to their complexity and the need for more components, such as four switches, compared to the simpler Half-Bridge design, which uses only two switches. Your choice between an H-Bridge and a Half-Bridge will significantly impact the overall budget, especially in applications requiring bidirectional motor control, where H-Bridges provide superior functionality at a premium price. For cost-sensitive projects with unidirectional control, Half-Bridge configurations offer a more economical solution without compromising basic performance.

Circuit Complexity and Design Considerations

H-bridge circuits typically involve four switches arranged in an "H" configuration, allowing bidirectional current flow and precise motor control, which increases circuit complexity compared to half-bridge designs. Half-bridge circuits use two switches and are simpler but support only unidirectional current, making them suitable for less complex applications with lower control requirements. Design considerations for H-bridge circuits must address increased gate drive circuitry and potential shoot-through protection, whereas half-bridge designs benefit from fewer components and simpler control logic.

Pros and Cons: H-Bridge vs Half-Bridge

H-Bridge circuits offer full control over motor direction with the ability to drive current both ways, making them ideal for bidirectional motor control but they tend to be more complex and costly due to having four switches. Half-Bridge configurations are simpler and more efficient for applications requiring unidirectional control or DC-DC converters, yet they cannot reverse motor direction without additional components. Your choice depends on whether you prioritize directional control flexibility or circuit simplicity and cost-effectiveness.

Which Bridge is Best for Your Application?

Choosing between an H-bridge and a half-bridge depends on your application's power and control requirements; H-bridges offer full bidirectional control of DC motors, making them ideal for precise speed and direction management in robotics or automotive systems. Half-bridges, providing simpler and more cost-effective solutions, excel in applications with less complex switching needs or where only unidirectional control is necessary. Evaluate the voltage, current ratings, and control complexity to determine which bridge best optimizes performance and efficiency for your project.

H-bridge vs Half-bridge Infographic

libmatt.com

libmatt.com