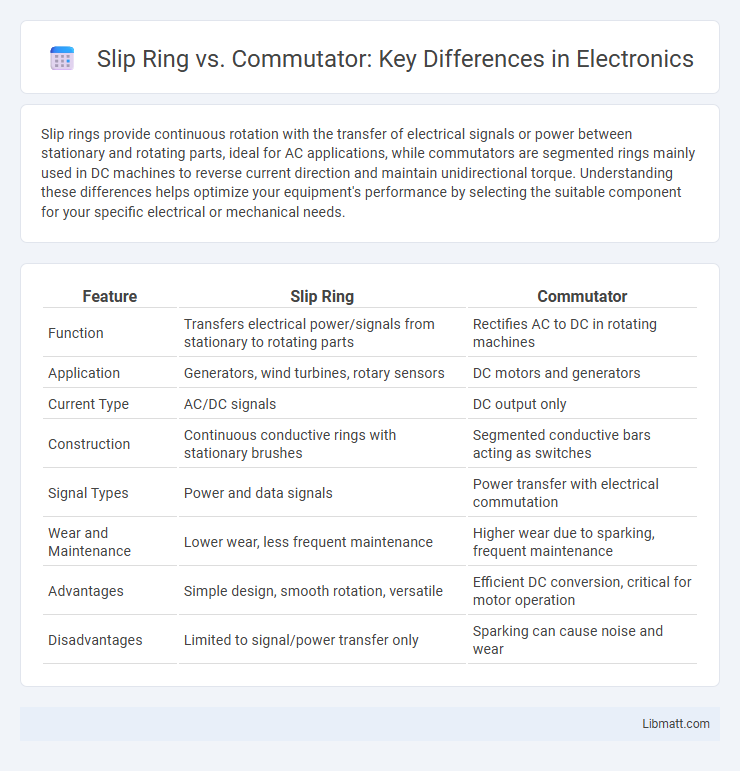

Slip rings provide continuous rotation with the transfer of electrical signals or power between stationary and rotating parts, ideal for AC applications, while commutators are segmented rings mainly used in DC machines to reverse current direction and maintain unidirectional torque. Understanding these differences helps optimize your equipment's performance by selecting the suitable component for your specific electrical or mechanical needs.

Table of Comparison

| Feature | Slip Ring | Commutator |

|---|---|---|

| Function | Transfers electrical power/signals from stationary to rotating parts | Rectifies AC to DC in rotating machines |

| Application | Generators, wind turbines, rotary sensors | DC motors and generators |

| Current Type | AC/DC signals | DC output only |

| Construction | Continuous conductive rings with stationary brushes | Segmented conductive bars acting as switches |

| Signal Types | Power and data signals | Power transfer with electrical commutation |

| Wear and Maintenance | Lower wear, less frequent maintenance | Higher wear due to sparking, frequent maintenance |

| Advantages | Simple design, smooth rotation, versatile | Efficient DC conversion, critical for motor operation |

| Disadvantages | Limited to signal/power transfer only | Sparking can cause noise and wear |

Introduction: Understanding Slip Rings and Commutators

Slip rings and commutators are essential components in electromechanical systems, enabling the transmission of electrical signals and power between stationary and rotating parts. Slip rings provide continuous rotary electrical connections, commonly used in applications like wind turbines and rotary sensors, allowing uninterrupted signal and power flow. Commutators function as mechanical switches in direct current (DC) machines, reversing current direction to maintain consistent torque and motor operation.

Basic Definition of Slip Ring

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary structure to a rotating one. Unlike a commutator, which is primarily used in DC machines to reverse the current direction, slip rings provide continuous electrical connection in AC systems or rotary joints. Your choice between a slip ring and a commutator depends on whether you need uninterrupted rotation with consistent signal transfer or periodic direction switching.

Basic Definition of Commutator

A commutator is a rotary electrical switch in certain types of electric motors and generators that reverses the direction of current flow through the rotor windings, ensuring continuous torque and smooth operation. Unlike slip rings, which provide a constant connection for AC signals, the commutator works specifically with direct current (DC) machines, converting alternating current in the rotor into direct current external to the machine. Your understanding of the commutator's fundamental role clarifies why it's essential for efficient DC motor function and differentiates it from slip ring applications.

Key Differences Between Slip Ring and Commutator

Slip rings and commutators are both rotary electrical interfaces, but slip rings transmit alternating current (AC) signals allowing continuous rotation without reversing polarity, while commutators convert alternating current into direct current (DC) by reversing polarity at specific intervals. Slip rings are used in applications requiring unidirectional signal transfer such as wind turbines and radar systems, whereas commutators are integral to DC motors and generators for maintaining current flow direction. Your choice depends on whether the device requires AC signal transmission or DC power conversion with polarity switching.

Construction and Design Comparison

Slip rings consist of continuous rings and stationary brushes that enable the transmission of electrical signals or power between rotating and stationary parts, featuring a simple, cylindrical design for smooth rotation. Commutators are segmented cylindrical components with multiple contacts and corresponding brushes, designed to reverse current direction in DC machines, resulting in more complex construction with insulation between segments. Your choice depends on whether continuous signal transmission or current commutation is required, influencing the structural design and functionality of these components.

Working Principle of Slip Rings

Slip rings operate by maintaining continuous electrical connections through rotating interfaces, allowing current to pass between stationary and rotating parts without twisting wires. Unlike commutators that convert alternating current to direct current, slip rings transmit signals or power in AC or DC circuits via sliding contacts on a rotating assembly. Your machinery benefits from slip rings' ability to provide smooth and reliable rotation while ensuring stable electrical conductivity.

Working Principle of Commutators

Commutators operate by reversing the direction of current flow through the armature windings in a DC motor or generator, ensuring unidirectional torque production and smooth rotation. They consist of segmented copper rings connected to the armature, with brushes maintaining electrical contact to switch current at precise intervals. Your device relies on this mechanical switching to convert AC induced in the armature into DC output.

Applications: Where Are Slip Rings Used?

Slip rings are predominantly used in rotating electrical equipment such as wind turbines, electric generators, and rotary sensors to transmit power and signals between stationary and rotating parts. Their applications extend to medical imaging devices like CT scanners, packaging machinery, and robotics, where continuous rotation combined with power or data transfer is essential. Unlike commutators, which are mainly found in DC motors and generators to reverse current direction, slip rings enable smooth electrical connections without interrupting the transmission in various industrial and renewable energy systems.

Applications: Where Are Commutators Used?

Commutators are primarily used in DC machines, such as DC motors and generators, to reverse the current direction and maintain continuous torque. Their applications span industries including electric vehicles, power tools, and industrial equipment where precise control of rotational motion is crucial. Understanding the role of commutators helps you optimize performance in systems requiring reliable and efficient motor operation.

Choosing Between Slip Ring and Commutator: Which One to Use?

Slip rings are ideal for applications requiring continuous rotation and transmission of power or signals, such as in wind turbines and rotating cameras, while commutators are better suited for converting alternating current to direct current in devices like DC motors and generators. Your choice depends on whether you need uninterrupted rotational movement with signal transfer or precise current direction control. Evaluating the operational requirements, maintenance needs, and electrical performance will help determine if a slip ring or commutator is more appropriate for your specific machinery.

Slip Ring vs Commutator Infographic

libmatt.com

libmatt.com