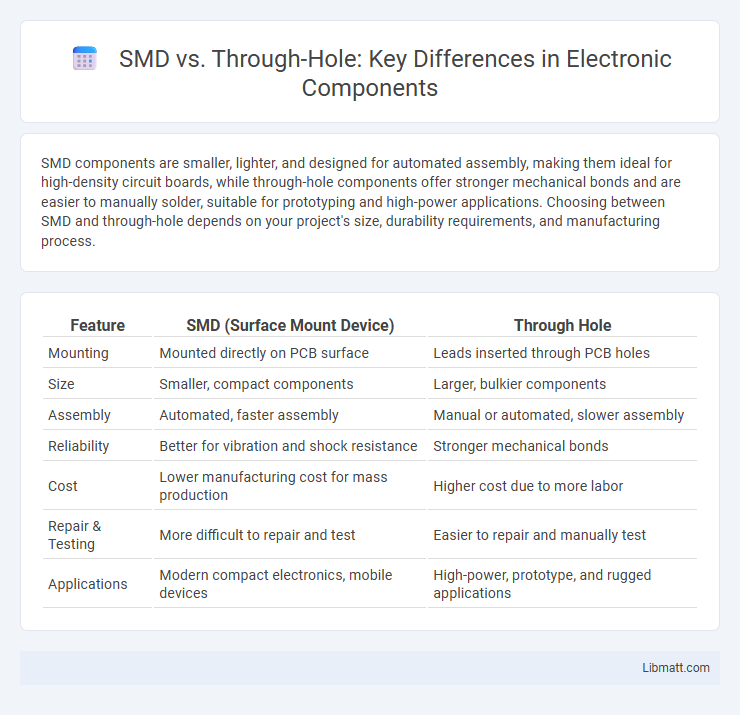

SMD components are smaller, lighter, and designed for automated assembly, making them ideal for high-density circuit boards, while through-hole components offer stronger mechanical bonds and are easier to manually solder, suitable for prototyping and high-power applications. Choosing between SMD and through-hole depends on your project's size, durability requirements, and manufacturing process.

Table of Comparison

| Feature | SMD (Surface Mount Device) | Through Hole |

|---|---|---|

| Mounting | Mounted directly on PCB surface | Leads inserted through PCB holes |

| Size | Smaller, compact components | Larger, bulkier components |

| Assembly | Automated, faster assembly | Manual or automated, slower assembly |

| Reliability | Better for vibration and shock resistance | Stronger mechanical bonds |

| Cost | Lower manufacturing cost for mass production | Higher cost due to more labor |

| Repair & Testing | More difficult to repair and test | Easier to repair and manually test |

| Applications | Modern compact electronics, mobile devices | High-power, prototype, and rugged applications |

Introduction to SMD and Through-Hole Technology

Surface Mount Device (SMD) technology involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), enabling higher component density and smaller circuit layouts. Through-hole technology requires inserting component leads into drilled holes on the PCB, providing stronger mechanical bonds and better durability under mechanical stress. SMD is preferred for compact, high-speed applications, while through-hole is commonly used in prototypes and devices needing robust connectivity.

Definition and Key Differences

Surface-Mount Device (SMD) components are mounted directly onto the surface of printed circuit boards (PCBs), while Through-Hole components have leads inserted into holes drilled through the PCB and soldered on the opposite side. SMDs enable higher circuit density and automated assembly, offering smaller size and faster production, whereas Through-Hole components provide stronger mechanical bonds suitable for high-stress applications. Understanding the distinction between these mounting techniques helps optimize your PCB design for performance, reliability, and manufacturing efficiency.

Historical Background and Evolution

Surface Mount Device (SMD) technology emerged in the 1960s as a response to the limitations of traditional Through Hole technology, which had dominated electronic assembly since the early 20th century. Through Hole components, characterized by leads inserted into drilled holes on printed circuit boards (PCBs), provided strong mechanical bonds but limited miniaturization and automated manufacturing capabilities. The evolution to SMD allowed for smaller, more complex, and higher-density circuit designs, driven by advances in automated placement equipment and reflow soldering processes, revolutionizing modern electronics manufacturing.

Advantages of SMD Components

SMD components offer significant advantages including smaller size, which allows for higher component density and more compact circuit designs. They provide better performance at high frequencies due to shorter leads and reduced parasitic inductance and capacitance. Your electronic devices benefit from automated assembly processes, enhancing manufacturing efficiency and reducing production costs.

Benefits of Through-Hole Technology

Through-hole technology offers superior mechanical strength, making it ideal for components subjected to physical stress or high power applications. It ensures reliable connections through the PCB, reducing the risk of component detachment during operation. Your designs benefit from increased durability and better performance in demanding environments with through-hole components.

Common Applications of SMD vs Through-Hole

Surface Mount Devices (SMD) are widely used in compact consumer electronics, smartphones, and high-density circuit boards due to their small size and automated assembly compatibility. Through-hole components, known for their robust mechanical strength, are preferred in applications requiring durability and heat resistance such as industrial machinery, power supplies, and prototypes. Your choice between SMD and through-hole depends on the desired reliability, assembly process, and space constraints of the application.

Assembly Process Comparison

Surface Mount Device (SMD) assembly uses automated machines that rapidly place components directly onto the PCB surface, significantly reducing production time and costs compared to the manual or semi-automatic insertion required for through-hole components. Through-hole assembly involves drilling holes into the PCB and inserting component leads through them, which often demands additional soldering steps like wave soldering, making it more labor-intensive. Your choice influences manufacturing speed, precision, and overall efficiency, with SMD offering higher automation and throughput for complex, high-volume projects.

Cost and Production Considerations

Surface-Mount Device (SMD) technology enables more compact, automated manufacturing processes, reducing labor costs and assembly time compared to Through-Hole techniques. Through-Hole components generally incur higher production expenses due to manual placement and more complex drilling requirements on PCBs. SMD is preferred for high-volume production runs because it offers cost efficiency and faster throughput, whereas Through-Hole suits low-volume, prototype, or mechanically robust applications despite higher costs.

Reliability and Durability Factors

SMD components exhibit higher reliability in high-frequency applications due to shorter lead lengths minimizing inductance and capacitance effects, while through-hole parts offer superior mechanical durability under vibration and thermal stress because of their stronger physical mounting. Your choice depends on the operational environment, with SMD preferred for compact, lightweight designs and through-hole favored in rugged conditions requiring enhanced shock resistance. Both technologies have distinctive longevity profiles, influenced by factors such as solder joint quality and substrate material compatibility.

Future Trends in Electronic Component Mounting

Surface Mount Devices (SMD) dominate future trends in electronic component mounting due to their compact size, higher component density, and compatibility with automation, enabling faster production and enhanced performance. Through-hole technology remains relevant for applications requiring robust mechanical strength and high reliability, particularly in automotive and aerospace industries. You can expect ongoing advancements in hybrid mounting solutions combining SMD's efficiency with through-hole durability to address evolving electronic design challenges.

SMD vs Through Hole Infographic

libmatt.com

libmatt.com