AC contactors are designed specifically for alternating current circuits, providing efficient switching and protection for motors and lighting systems, while DC contactors handle direct current applications with specialized contacts to prevent arcing and ensure reliable operation. Understanding the differences helps you select the right contactor type for your electrical system's voltage and current requirements.

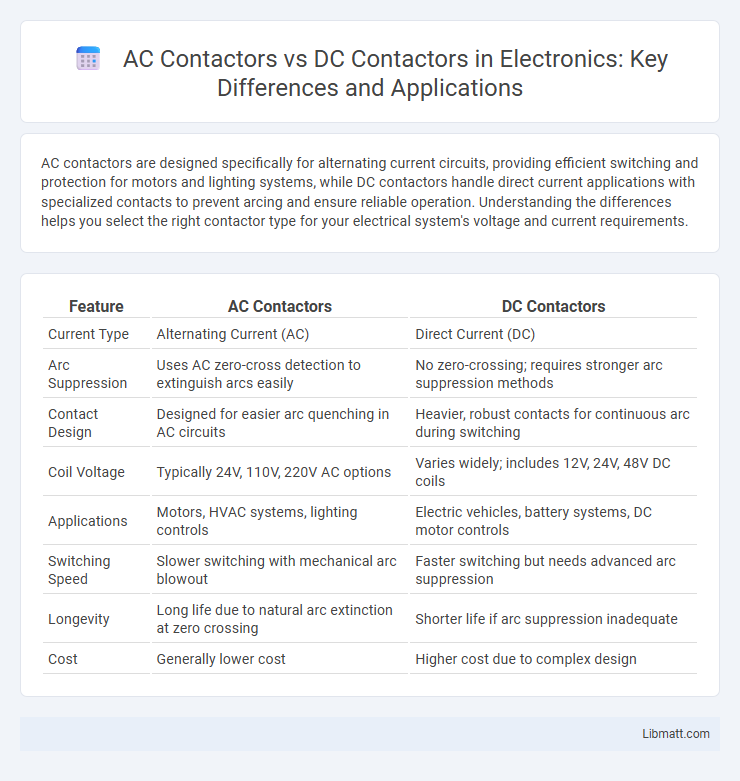

Table of Comparison

| Feature | AC Contactors | DC Contactors |

|---|---|---|

| Current Type | Alternating Current (AC) | Direct Current (DC) |

| Arc Suppression | Uses AC zero-cross detection to extinguish arcs easily | No zero-crossing; requires stronger arc suppression methods |

| Contact Design | Designed for easier arc quenching in AC circuits | Heavier, robust contacts for continuous arc during switching |

| Coil Voltage | Typically 24V, 110V, 220V AC options | Varies widely; includes 12V, 24V, 48V DC coils |

| Applications | Motors, HVAC systems, lighting controls | Electric vehicles, battery systems, DC motor controls |

| Switching Speed | Slower switching with mechanical arc blowout | Faster switching but needs advanced arc suppression |

| Longevity | Long life due to natural arc extinction at zero crossing | Shorter life if arc suppression inadequate |

| Cost | Generally lower cost | Higher cost due to complex design |

Introduction to Contactors: AC vs DC

AC contactors are designed to control alternating current circuits and typically feature coil voltages and contact materials optimized for AC voltage fluctuations. DC contactors handle direct current circuits, requiring specialized coil design to overcome the absence of zero crossing points and contacts resistant to arcing caused by continuous DC flow. Understanding these fundamental differences helps you select the appropriate contactor for your specific electrical application, ensuring reliability and efficiency.

Fundamental Differences Between AC and DC Contactors

AC contactors are designed to handle alternating current with coil characteristics optimized for AC electromagnetism, while DC contactors are built to manage direct current circuits with coils that produce a steady magnetic field. The fundamental difference lies in how each contactor deals with arc suppression; AC contactors benefit from the natural zero-crossing point of AC current to extinguish arcs, whereas DC contactors require more robust arc-quenching mechanisms due to the continuous flow of current. Your application should consider these operational distinctions to ensure optimal performance and safety in switching electrical loads.

Working Principles of AC Contactors

AC contactors operate by using an electromagnet coil powered by alternating current to generate a magnetic field that attracts the armature, closing the contacts and completing the circuit. The alternating current causes the magnetic field to constantly change direction, requiring the contactor design to minimize eddy currents and hysteresis losses through laminated cores and special coil windings. This mechanism ensures efficient switching for AC loads, making AC contactors essential components in industrial motor controllers and electrical distribution systems.

Working Principles of DC Contactors

DC contactors operate by utilizing an electromagnetic coil that generates a magnetic field when energized, attracting the movable core to close the circuit. Unlike AC contactors, they must overcome continuous magnetic flux without zero-crossing, requiring specially designed contacts and magnetic circuits to prevent welding and ensure reliable switching. Your system's performance depends on selecting DC contactors with appropriate voltage ratings and arc suppression features to handle the steady current flow effectively.

Key Components and Construction

AC contactors consist of a coil, movable armature, fixed contacts, and an iron core designed to handle alternating current's changing magnetic fields, ensuring smooth operation with minimal arc formation. DC contactors feature a similar coil and contact assembly but include specialized arc chutes and stronger magnetic materials to manage the continuous current flow and prevent contact welding under direct current. Your choice between AC and DC contactors should consider these construction differences to ensure optimal performance in your electrical system.

Applications of AC Contactors

AC contactors are widely used in industrial automation, motor control, lighting circuits, and HVAC systems due to their ability to handle alternating current efficiently. Their design supports switching high voltage and high current AC loads, making them ideal for pumps, compressors, and conveyor systems. You can rely on AC contactors for reliable performance in environments requiring frequent switching of AC power.

Applications of DC Contactors

DC contactors are primarily used in applications requiring the control of direct current circuits, such as electric vehicles, battery systems, and solar power installations, where stable and efficient switching is crucial. They play a vital role in industrial machinery, electric traction, and renewable energy systems by providing reliable operation under high current and voltage conditions. Their design allows for rapid breaking of DC circuits, preventing arcing and ensuring safety in energy storage and distribution networks.

Advantages and Disadvantages of AC Contactors

AC contactors offer advantages such as simpler coil design, resulting in lower power consumption and cost-effective operation in alternating current circuits. Their ability to handle frequent switching with reduced arcing improves reliability and lifespan, making them ideal for industrial motor controls. However, AC contactors can experience issues with contact wear due to inductive loads, and their coil performance may vary with voltage fluctuations, limiting their effectiveness in certain precise control applications.

Advantages and Disadvantages of DC Contactors

DC contactors offer precise control for direct current circuits, featuring enhanced arc suppression and longer contact life compared to AC contactors. However, they tend to be more expensive, larger in size, and require more complex maintenance due to the continuous arc generated when breaking DC current. Your choice of contactor should consider these factors based on the specific requirements of your electrical system.

Choosing the Right Contactor: AC or DC?

Selecting the appropriate contactor depends on the electrical system voltage and current type, with AC contactors designed for alternating current applications and DC contactors optimized for direct current loads. AC contactors typically feature electromagnetic coils that handle the inductive nature of AC circuits, while DC contactors require specialized arc suppression to manage continuous current flow without zero crossings. Properly matching the contactor type to the system ensures efficient switching, minimizes wear, and enhances overall reliability in industrial and commercial electrical installations.

AC Contactors vs DC Contactors Infographic

libmatt.com

libmatt.com