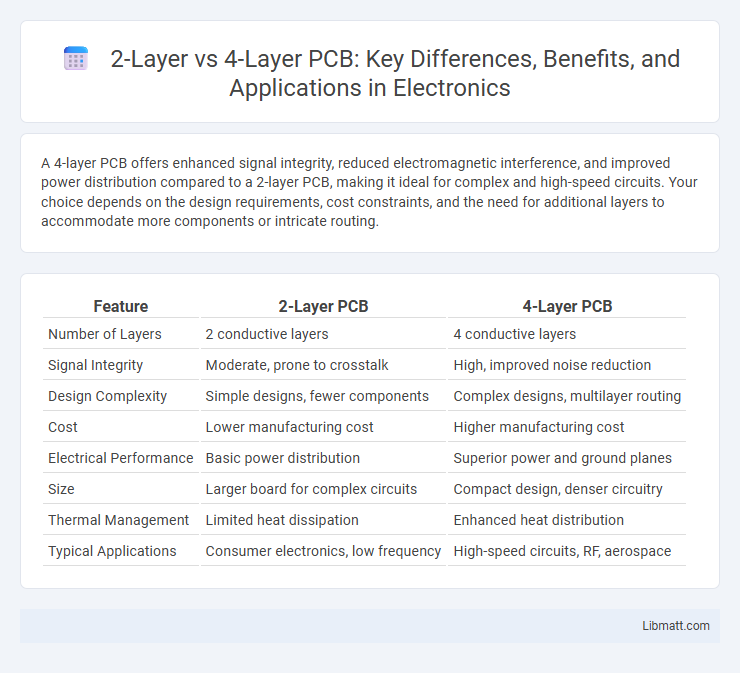

A 4-layer PCB offers enhanced signal integrity, reduced electromagnetic interference, and improved power distribution compared to a 2-layer PCB, making it ideal for complex and high-speed circuits. Your choice depends on the design requirements, cost constraints, and the need for additional layers to accommodate more components or intricate routing.

Table of Comparison

| Feature | 2-Layer PCB | 4-Layer PCB |

|---|---|---|

| Number of Layers | 2 conductive layers | 4 conductive layers |

| Signal Integrity | Moderate, prone to crosstalk | High, improved noise reduction |

| Design Complexity | Simple designs, fewer components | Complex designs, multilayer routing |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Electrical Performance | Basic power distribution | Superior power and ground planes |

| Size | Larger board for complex circuits | Compact design, denser circuitry |

| Thermal Management | Limited heat dissipation | Enhanced heat distribution |

| Typical Applications | Consumer electronics, low frequency | High-speed circuits, RF, aerospace |

Introduction to PCB Layer Structures

2-layer PCBs consist of two conductive layers separated by an insulating substrate, offering simple routing and cost-effective designs ideal for basic electronic devices. In contrast, 4-layer PCBs incorporate two additional internal layers, enabling complex signal routing, enhanced electrical performance, and better power distribution. The increased layer count in 4-layer PCBs supports higher component density and improved EMI shielding, making them suitable for advanced applications.

What is a 2-Layer PCB?

A 2-layer PCB consists of two conductive copper layers separated by an insulating substrate, enabling circuits to be routed on both the top and bottom surfaces. This design simplifies manufacturing and reduces costs while providing sufficient functionality for many electronic applications. Your choice between 2-layer and 4-layer PCBs depends on factors like signal complexity, electromagnetic interference management, and size constraints.

What is a 4-Layer PCB?

A 4-layer PCB consists of four conductive layers stacked together, typically including two signal layers, one power plane, and one ground plane. This design enhances electrical performance by reducing electromagnetic interference and providing better signal integrity compared to a 2-layer PCB. Your projects benefit from improved noise reduction, higher component density, and more complex routing options with a 4-layer PCB.

Key Differences Between 2-Layer and 4-Layer PCBs

2-layer PCBs consist of two conductive copper layers separated by an insulating layer, making them suitable for simple, low-density circuits and cost-effective applications. 4-layer PCBs add two more internal layers dedicated to power and ground planes, enhancing electromagnetic interference (EMI) reduction, signal integrity, and supporting more complex circuit designs. Your choice between 2-layer and 4-layer PCBs depends on the performance requirements, with 4-layer boards offering improved reliability and better heat dissipation for advanced electronics.

Electrical Performance: 2-Layer vs 4-Layer PCBs

4-layer PCBs offer superior electrical performance compared to 2-layer PCBs due to their additional internal power and ground planes, which reduce electromagnetic interference (EMI) and provide better signal integrity. The controlled impedance and decreased crosstalk in 4-layer designs enable higher-speed signal transmission, making them ideal for complex, high-frequency applications. In contrast, 2-layer PCBs have limited routing space and less effective noise shielding, which can lead to signal degradation and reduced overall electrical reliability.

Signal Integrity and Noise Reduction

A 4-layer PCB offers superior signal integrity compared to a 2-layer PCB due to dedicated ground and power planes that reduce electromagnetic interference and provide consistent reference voltages. The internal layers in a 4-layer design minimize crosstalk and noise coupling, essential for high-speed or sensitive circuits where maintaining clear signal transmission is critical. Your choice of a 4-layer PCB can significantly enhance noise reduction and performance stability, especially in complex or high-frequency applications.

Manufacturing Complexity and Cost

2-layer PCBs feature simpler manufacturing processes with one conductive layer on each side, resulting in lower production costs and faster turnaround times. In contrast, 4-layer PCBs require additional inner layers, increasing fabrication complexity due to precise alignment and insulation requirements, which raises both manufacturing time and expenses. Choosing between these options depends on your project's complexity, budget, and performance needs, with 2-layer boards suited for simpler designs and 4-layer boards offering enhanced electrical performance at a higher cost.

Applications and Use Cases

2-layer PCBs are widely used in simple consumer electronics, such as calculators and LED lighting, due to their cost-effectiveness and ease of manufacturing. 4-layer PCBs provide enhanced electrical performance and heat dissipation, making them ideal for complex applications like computers, smartphones, and automotive control systems. Depending on Your project's complexity and signal integrity requirements, selecting the appropriate PCB layer count is crucial for optimal functionality.

Choosing the Right PCB Layer for Your Project

Selecting between a 2-layer and 4-layer PCB hinges on factors like signal integrity, design complexity, and budget. 2-layer PCBs offer cost-effective solutions for simple circuits with moderate component density, while 4-layer PCBs provide enhanced grounding, reduced electromagnetic interference, and better performance for high-speed or complex applications. Your project requirements dictate the optimal choice to ensure reliability and functionality.

Summary: Comparing 2-Layer and 4-Layer PCBs

2-layer PCBs consist of two conductive layers, offering simpler design and lower cost, ideal for basic electronic devices with less complex circuits. In contrast, 4-layer PCBs provide additional layers for power and ground planes, enhancing signal integrity, reducing electromagnetic interference (EMI), and supporting higher-density, multilayer circuits. Choosing between 2-layer and 4-layer PCBs depends on factors like circuit complexity, performance requirements, manufacturing budget, and component density.

2-layer vs 4-layer PCB Infographic

libmatt.com

libmatt.com