Analog isolators transmit continuous signals using analog methods, ensuring minimal signal distortion in sensitive applications, while digital isolators transfer discrete digital signals with high-speed data rates and enhanced noise immunity. Understanding the key differences helps you choose the appropriate isolator for precise signal integrity or fast, reliable data communication.

Table of Comparison

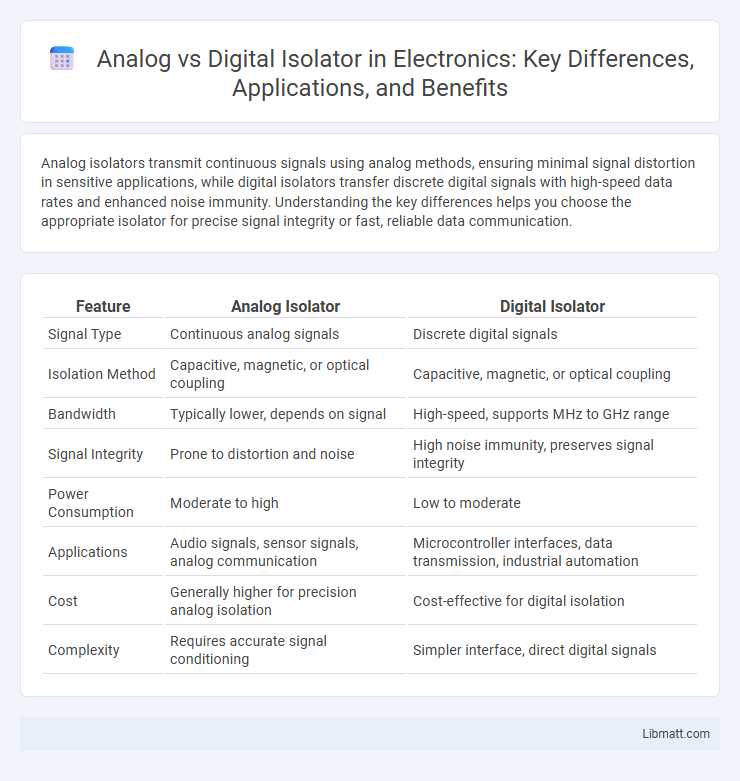

| Feature | Analog Isolator | Digital Isolator |

|---|---|---|

| Signal Type | Continuous analog signals | Discrete digital signals |

| Isolation Method | Capacitive, magnetic, or optical coupling | Capacitive, magnetic, or optical coupling |

| Bandwidth | Typically lower, depends on signal | High-speed, supports MHz to GHz range |

| Signal Integrity | Prone to distortion and noise | High noise immunity, preserves signal integrity |

| Power Consumption | Moderate to high | Low to moderate |

| Applications | Audio signals, sensor signals, analog communication | Microcontroller interfaces, data transmission, industrial automation |

| Cost | Generally higher for precision analog isolation | Cost-effective for digital isolation |

| Complexity | Requires accurate signal conditioning | Simpler interface, direct digital signals |

Introduction to Signal Isolation

Signal isolation ensures the safe transfer of electrical signals between circuits operating at different voltage levels or environments, preventing ground loops and electrical noise interference. Analog isolators use transformers, capacitors, or optical components to transmit continuous signals with minimal distortion, ideal for sensitive analog measurements. Digital isolators employ high-speed digital data transmission techniques like capacitive or magnetic coupling to achieve robust noise immunity and faster signal processing, enhancing Your system's reliability in harsh industrial or medical applications.

What is an Analog Isolator?

An analog isolator is an electronic component designed to transfer analog signals across isolated domains while maintaining electrical separation. It prevents ground loop interference and noise by using capacitive, magnetic, or optical coupling techniques without converting the signal to digital form. Analog isolators are essential in sensitive measurement and industrial control systems where signal integrity and safety are critical.

What is a Digital Isolator?

A digital isolator is an electronic component that provides galvanic isolation between high-voltage and low-voltage circuits while transmitting digital signals with high-speed and low power consumption. Unlike traditional optocouplers, digital isolators use capacitive, magnetic, or RF coupling to achieve isolation, enhancing signal integrity and reducing size. These devices are critical in applications requiring safe and reliable data transfer across different voltage domains, such as industrial automation and medical equipment.

Key Differences: Analog vs Digital Isolators

Analog isolators transmit continuous signals, preserving signal integrity in applications requiring precise voltage or current measurement, while digital isolators transmit discrete, binary signals suitable for digital data communication. Analog isolators typically use capacitive or optical methods to maintain linearity and low distortion, whereas digital isolators employ high-speed digital encoding for noise immunity and faster data rates. Key differences include signal type handling, speed, isolation methods, and application focus, with digital isolators favored for robust, high-speed environments and analog isolators preferred for sensitive, low-frequency analog signal transmission.

Performance Comparison: Speed, Accuracy, and Noise Immunity

Analog isolators offer high accuracy and excellent noise immunity due to continuous signal transmission but typically operate at lower speeds compared to digital isolators. Digital isolators provide faster data transfer rates with robust noise immunity by employing digital encoding techniques, though they may introduce quantization errors affecting precision. Performance choice depends on application needs where analog isolators excel in signal fidelity, while digital isolators prioritize speed and strong electrical noise resistance.

Applications of Analog Isolators

Analog isolators are widely used in industrial automation systems to provide galvanic isolation while maintaining signal fidelity in sensor interfaces and data acquisition modules. They are essential in medical equipment for isolating patient-connected circuitry from high-voltage components, enhancing safety and preventing electrical interference. Analog isolators also find applications in motor control systems and power electronics, enabling precise analog signal transfer across isolation barriers without distortion.

Applications of Digital Isolators

Digital isolators find extensive applications in industrial automation, medical devices, and communication systems due to their ability to provide high-speed data transmission with robust galvanic isolation. They are essential for protecting sensitive microcontrollers and signal processing units from high voltage spikes and ground loops in power electronics and motor control systems. Their use in isolated data interfaces enhances system reliability and noise immunity in harsh electrical environments.

Advantages and Disadvantages

Analog isolators provide superior noise immunity and signal integrity for low-frequency or continuous signals, making them ideal for sensitive sensor applications; however, they often suffer from limited bandwidth and size constraints. Digital isolators offer high-speed data transmission with lower power consumption and greater robustness against electromagnetic interference, yet they can introduce latency and lack the continuous signal preservation required for analog waveforms. Choosing between analog and digital isolators depends on the application's requirements for signal type, speed, isolation voltage, and power efficiency.

Selection Criteria for Isolator Technology

Selection criteria for isolator technology hinge on signal integrity, data rate requirements, and environmental conditions. Analog isolators excel in preserving waveform fidelity for low-frequency signals, while digital isolators support higher data rates with robust noise immunity. Key factors include isolation voltage rating, propagation delay, power consumption, and compliance with safety standards such as IEC 60747.

Future Trends in Isolation Technology

Future trends in isolation technology emphasize the integration of AI-powered adaptive isolation systems and enhanced data throughput capabilities in digital isolators, driving higher precision and reduced latency. Innovations in ultra-low power consumption and silicon carbide (SiC) based analog isolators expand application possibilities in electric vehicles and industrial automation. Hybrid isolators combining analog robustness with digital flexibility are emerging to meet complex system requirements in smart grids and industrial IoT.

Analog vs Digital isolator Infographic

libmatt.com

libmatt.com