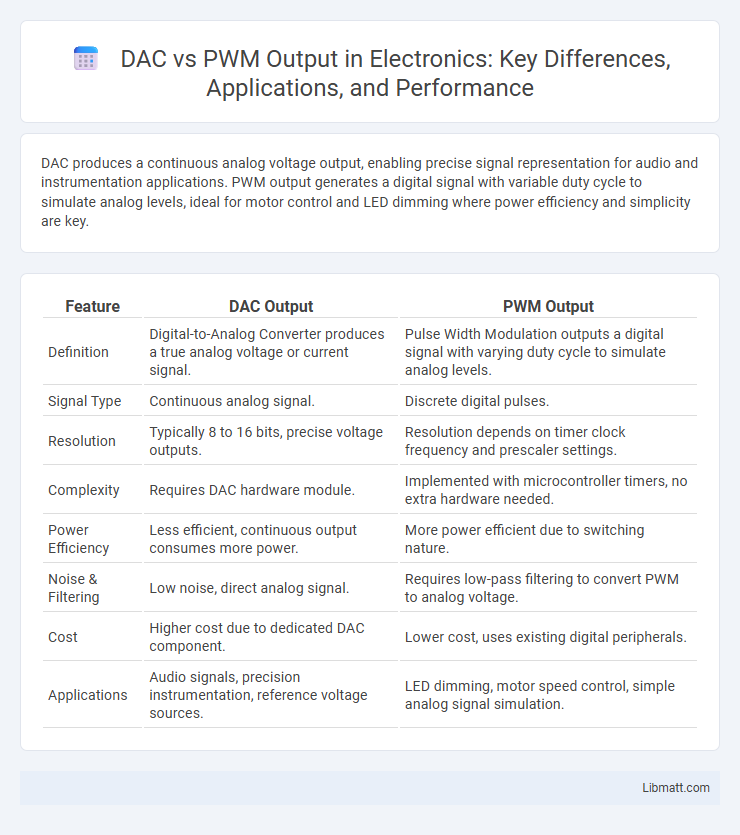

DAC produces a continuous analog voltage output, enabling precise signal representation for audio and instrumentation applications. PWM output generates a digital signal with variable duty cycle to simulate analog levels, ideal for motor control and LED dimming where power efficiency and simplicity are key.

Table of Comparison

| Feature | DAC Output | PWM Output |

|---|---|---|

| Definition | Digital-to-Analog Converter produces a true analog voltage or current signal. | Pulse Width Modulation outputs a digital signal with varying duty cycle to simulate analog levels. |

| Signal Type | Continuous analog signal. | Discrete digital pulses. |

| Resolution | Typically 8 to 16 bits, precise voltage outputs. | Resolution depends on timer clock frequency and prescaler settings. |

| Complexity | Requires DAC hardware module. | Implemented with microcontroller timers, no extra hardware needed. |

| Power Efficiency | Less efficient, continuous output consumes more power. | More power efficient due to switching nature. |

| Noise & Filtering | Low noise, direct analog signal. | Requires low-pass filtering to convert PWM to analog voltage. |

| Cost | Higher cost due to dedicated DAC component. | Lower cost, uses existing digital peripherals. |

| Applications | Audio signals, precision instrumentation, reference voltage sources. | LED dimming, motor speed control, simple analog signal simulation. |

Introduction: Understanding DAC and PWM Output

Digital-to-Analog Converters (DAC) transform digital signals into continuous analog voltages, ensuring precise voltage levels suitable for audio, sensors, and instrumentation. Pulse Width Modulation (PWM) output controls the average voltage by switching digital signals on and off at a high frequency, effectively simulating analog values through duty cycle variation. Both DAC and PWM play crucial roles in embedded systems, with DAC offering smooth analog output and PWM providing efficient, cost-effective signal control.

Key Differences Between DAC and PWM

DAC generates a continuous analog voltage output by converting digital signals into corresponding voltage levels, delivering precise and smooth signal representation. PWM outputs a digital square wave with varying duty cycle to simulate analog voltage levels through average voltage over time, ideal for power control and signal modulation. Key differences include DAC's true analog output versus PWM's digitally modulated signal, with DAC offering higher accuracy and resolution while PWM provides efficient switching and simpler implementation.

How DAC Works: Principles and Applications

A Digital-to-Analog Converter (DAC) transforms discrete digital signals into continuous analog voltages by assigning specific voltage levels to binary input codes using components like resistor ladders or switched capacitor networks. This precise voltage output enables accurate audio reproduction, sensor signal conditioning, and instrumentation control in applications requiring smooth and stable analog signals. Understanding how a DAC operates helps optimize your system design for high-fidelity sound or precise measurement tasks.

How PWM Output Works: Concepts and Use Cases

PWM output modulates the width of voltage pulses to control power delivery, effectively simulating an analog signal by varying the duty cycle between 0% and 100%. This technique is widely used in applications such as motor speed control, LED dimming, and audio signal generation due to its efficiency and simplicity. Your circuits benefit from PWM's ability to reduce heat dissipation compared to linear analog output methods while maintaining precise control over output levels.

Signal Quality: Analog Smoothness vs Digital Pulses

DAC output provides superior signal quality with smooth, continuous analog voltage levels that closely mimic natural waveforms. PWM output, on the other hand, delivers digital pulses that require filtering to approximate analog signals, often resulting in less smoothness and potential noise. Your choice between DAC and PWM influences the fidelity and clarity of the signal, especially in applications demanding precise analog control.

Resolution and Accuracy: DAC vs PWM

DAC output offers higher resolution and accuracy by providing a continuous analog voltage that precisely represents input values, typically measured in bits such as 8-bit, 10-bit, or 12-bit resolution. PWM output, while simpler and cost-effective, approximates analog signals using digital pulses with varying duty cycles, resulting in lower resolution limited by the PWM frequency and timer resolution. In applications demanding fine voltage control and stable output, DACs outperform PWM due to minimal quantization noise and inherent linearity.

Power Efficiency Comparison

DAC (Digital-to-Analog Converter) outputs provide precise voltage levels with inherently lower noise, but often consume more power due to continuous analog signal generation. PWM (Pulse-Width Modulation) outputs achieve higher power efficiency by switching digital signals rapidly, minimizing energy loss in driving loads or motors. Your choice between DAC and PWM should consider the trade-off between accuracy and power consumption in your specific application.

Cost and Complexity: Implementation Considerations

Digital-to-Analog Converters (DACs) generally entail higher cost and complexity due to precision components and calibration requirements, making them suitable for applications demanding accurate and stable analog signals. Pulse Width Modulation (PWM) output systems offer a more cost-effective and simpler implementation by using digital signals with varying duty cycles, ideal for controlling power or simulating analog levels with added filtering. Engineers often select PWM for budget-sensitive projects where complexity reduction is critical, whereas DACs fit scenarios requiring high-fidelity analog output despite increased expenditure.

Common Use Cases for DAC and PWM Outputs

DAC outputs are commonly used in audio signal processing, precise sensor data conversion, and waveform generation where exact voltage levels are required. PWM outputs find frequent applications in motor speed control, LED dimming, and power delivery systems due to their efficient signal modulation. Both DAC and PWM technologies serve critical roles in embedded systems and instrumentation, tailored to different analog output performance needs.

Choosing the Right Output: DAC or PWM?

Choosing between DAC and PWM output depends on the precision and signal quality required for your application. DAC (Digital-to-Analog Converter) provides a smooth, continuous analog signal ideal for audio and sensor interfacing. PWM (Pulse Width Modulation) offers efficient control for power delivery and motor speed, but requires filtering to achieve a stable analog output.

DAC vs PWM Output Infographic

libmatt.com

libmatt.com