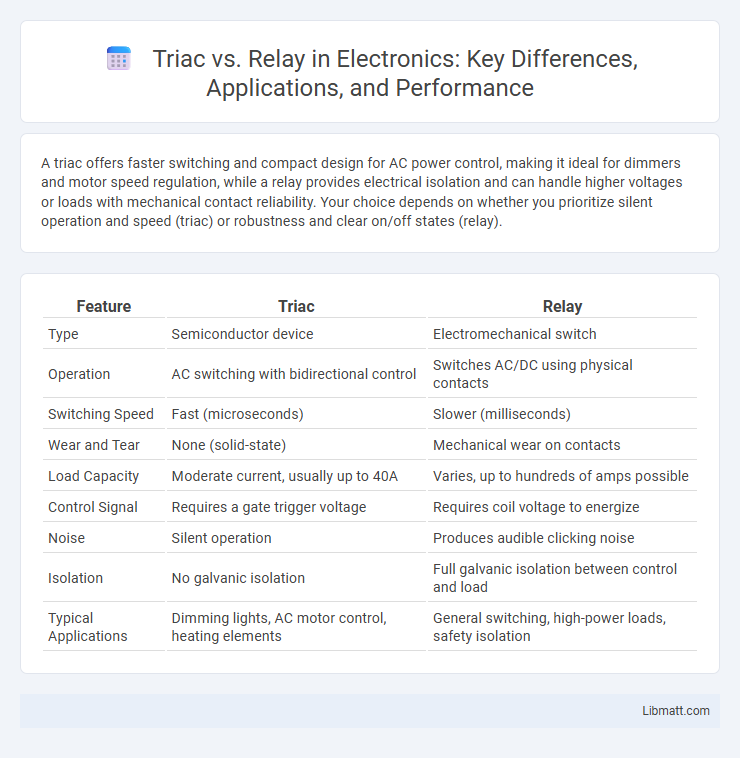

A triac offers faster switching and compact design for AC power control, making it ideal for dimmers and motor speed regulation, while a relay provides electrical isolation and can handle higher voltages or loads with mechanical contact reliability. Your choice depends on whether you prioritize silent operation and speed (triac) or robustness and clear on/off states (relay).

Table of Comparison

| Feature | Triac | Relay |

|---|---|---|

| Type | Semiconductor device | Electromechanical switch |

| Operation | AC switching with bidirectional control | Switches AC/DC using physical contacts |

| Switching Speed | Fast (microseconds) | Slower (milliseconds) |

| Wear and Tear | None (solid-state) | Mechanical wear on contacts |

| Load Capacity | Moderate current, usually up to 40A | Varies, up to hundreds of amps possible |

| Control Signal | Requires a gate trigger voltage | Requires coil voltage to energize |

| Noise | Silent operation | Produces audible clicking noise |

| Isolation | No galvanic isolation | Full galvanic isolation between control and load |

| Typical Applications | Dimming lights, AC motor control, heating elements | General switching, high-power loads, safety isolation |

Introduction to Triac and Relay

A Triac is a semiconductor device that controls AC power by switching current on and off during both halves of the waveform, enabling efficient, silent operation and precise dimming in lighting or motor control applications. A Relay is an electromechanical switch that uses an electromagnetic coil to mechanically open or close contacts, providing electrical isolation and the ability to switch high-current loads with reliability. Your choice between a Triac and a Relay depends on factors like switching speed, noise tolerance, and load type in your electrical control system.

Basic Working Principles

A Triac is a semiconductor device that controls AC power by switching current on and off through a single component, enabling precise and silent operation. A Relay uses an electromagnetic coil to mechanically open or close contacts, physically controlling the circuit and providing electrical isolation. Your choice depends on whether you need fast, noise-free switching or high-voltage isolation in your application.

Key Differences Between Triacs and Relays

Triacs are solid-state semiconductor devices that control AC power by switching current in both directions, enabling silent and fast operation with no mechanical wear. Relays use electromagnetic coils to mechanically open or close contacts, providing galvanic isolation and handling higher inrush currents but with limited switching speed and audible noise. The main differences lie in their operation mechanisms, durability, switching speed, and suitability for AC load control versus isolation requirements.

Common Applications

Triacs excel in controlling AC power for dimming lights, motor speed regulation, and heater control in household appliances due to their silent switching and compact size. Relays are preferred in automotive systems, industrial machinery, and high-current applications where electrical isolation and the ability to switch DC loads are critical. Your choice depends on the specific need for silent operation and speed (Triac) versus robustness and load versatility (Relay).

Advantages of Using Triacs

Triacs offer faster switching speeds and greater efficiency compared to relays, making them ideal for applications requiring rapid and frequent on/off cycles. They operate silently without mechanical contacts, which reduces wear and extends device lifespan, especially in high-load environments. Additionally, Triacs provide precise control over AC power, enabling smooth phase angle modulation in lighting and motor speed control.

Advantages of Using Relays

Relays offer superior electrical isolation between control and load circuits, enhancing safety in high-voltage applications. Their ability to handle both AC and DC loads with minimal signal interference makes them versatile for various industrial uses. Mechanical contacts ensure reliable switching for loads with high inrush currents, which can be challenging for solid-state devices like Triacs.

Limitations and Drawbacks

Triacs face limitations such as inability to switch direct current efficiently and susceptibility to false triggering due to voltage spikes. Relays have drawbacks including mechanical wear leading to shorter lifespan, slower switching speeds, and larger physical size compared to semiconductor alternatives. Both components may generate electromagnetic interference, but relays also produce audible noise during operation.

Selection Criteria: Triac or Relay?

Selection criteria between triac and relay focus on load type, switching speed, and electrical isolation. Triacs excel in controlling AC loads with fast, silent switching suitable for dimmers and motor controls, while relays provide robust isolation and handle both AC and DC loads with higher current ratings. Consider voltage, current requirements, switching frequency, and cost efficiency when choosing between triac and relay for specific applications.

Safety and Maintenance Considerations

Triacs provide enhanced safety through solid-state design, eliminating mechanical contacts that can wear out or spark, reducing fire hazards. Relays, with physical contacts, require regular inspection and maintenance to prevent contact degradation and ensure reliable operation. Choosing triacs minimizes maintenance needs and enhances longevity, especially in environments with frequent switching or vibration.

Future Trends in Switching Technology

Triacs and relays both play critical roles in switching technology, but future trends favor solid-state devices like triacs due to their faster switching speeds and longer lifespans. Innovations in semiconductor materials and integrated circuits enhance triac efficiency, enabling smarter and more energy-efficient power control solutions. Your choice of switching technology should consider these advancements for improved performance and durability in next-generation electronic systems.

Triac vs Relay Infographic

libmatt.com

libmatt.com