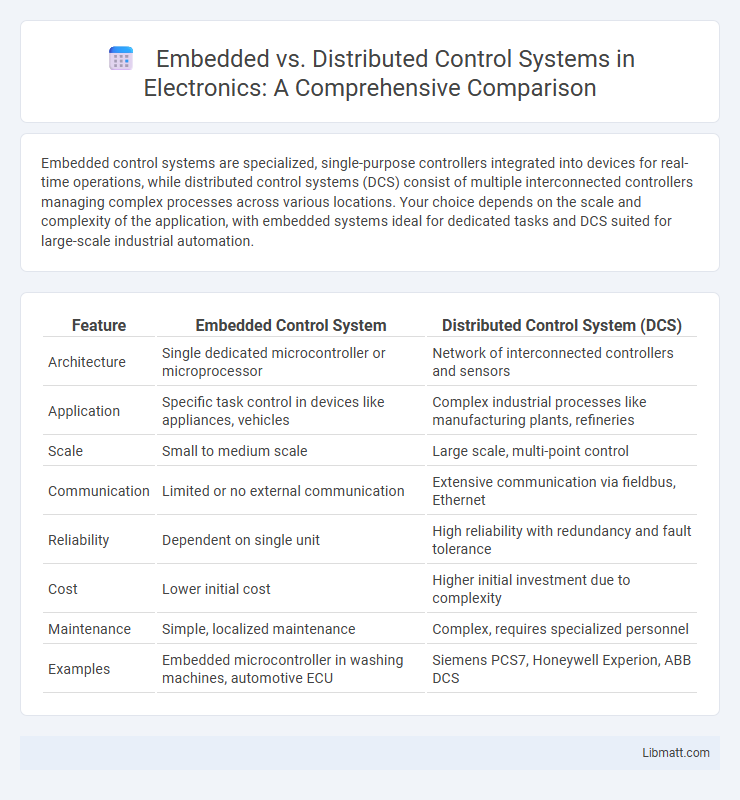

Embedded control systems are specialized, single-purpose controllers integrated into devices for real-time operations, while distributed control systems (DCS) consist of multiple interconnected controllers managing complex processes across various locations. Your choice depends on the scale and complexity of the application, with embedded systems ideal for dedicated tasks and DCS suited for large-scale industrial automation.

Table of Comparison

| Feature | Embedded Control System | Distributed Control System (DCS) |

|---|---|---|

| Architecture | Single dedicated microcontroller or microprocessor | Network of interconnected controllers and sensors |

| Application | Specific task control in devices like appliances, vehicles | Complex industrial processes like manufacturing plants, refineries |

| Scale | Small to medium scale | Large scale, multi-point control |

| Communication | Limited or no external communication | Extensive communication via fieldbus, Ethernet |

| Reliability | Dependent on single unit | High reliability with redundancy and fault tolerance |

| Cost | Lower initial cost | Higher initial investment due to complexity |

| Maintenance | Simple, localized maintenance | Complex, requires specialized personnel |

| Examples | Embedded microcontroller in washing machines, automotive ECU | Siemens PCS7, Honeywell Experion, ABB DCS |

Introduction to Control Systems

Embedded control systems are dedicated processors designed to perform specific control functions within a larger device, offering real-time processing and high reliability for tasks like automotive engine management or industrial automation. Distributed control systems (DCS) consist of multiple interconnected controllers spread across different locations, managing complex processes such as power plants or chemical manufacturing with enhanced scalability and redundancy. Understanding these control architectures helps you select the optimal system for precise, efficient, and reliable operation tailored to your application needs.

What is an Embedded Control System?

An Embedded Control System is a specialized computing system designed to perform dedicated functions within a larger mechanical or electrical system, integrating hardware and software to manage real-time operations. These systems are characterized by their tight integration with sensors and actuators, enabling precise monitoring and control of specific processes, often with stringent timing constraints. Embedded control systems are commonly found in automotive, aerospace, and industrial applications where reliability, efficiency, and real-time performance are critical.

What is a Distributed Control System?

A Distributed Control System (DCS) is an architecture used to control complex industrial processes by distributing control elements across multiple interconnected controllers rather than relying on a single central unit. This system enhances reliability and scalability by enabling localized control and real-time communication between controllers, sensors, and actuators through a high-speed network. DCS is commonly deployed in manufacturing sectors such as oil refining, chemical production, and power generation, where precise and continuous process management is critical.

Core Components of Each System

Embedded control systems consist of microcontrollers or microprocessors, sensors, actuators, and real-time operating systems designed for dedicated tasks within a single device. Distributed control systems incorporate multiple interconnected controllers, communication networks, and centralized supervisory systems to manage complex processes across various locations. Your choice depends on whether you require localized precision control or a scalable solution for large-scale industrial automation.

Key Differences Between Embedded and Distributed Control Systems

Embedded control systems are designed for specific, real-time tasks within a single device, featuring tight integration of hardware and software for optimized performance and reliability. Distributed control systems (DCS) involve a network of interconnected controllers spread across multiple locations to manage complex industrial processes with enhanced scalability, fault tolerance, and centralized monitoring. Key differences include the scope of control, system architecture, and communication methods, with embedded systems being localized and dedicated, while distributed control systems emphasize modularity and networked coordination.

Advantages of Embedded Control Systems

Embedded control systems offer advantages such as faster response times and higher reliability due to their dedicated hardware and software integration. They provide optimized performance for specific tasks with lower power consumption and reduced system complexity. Your application benefits from real-time processing capabilities and enhanced security by minimizing external communication risks.

Benefits of Distributed Control Systems

Distributed Control Systems (DCS) offer enhanced fault tolerance and scalability by decentralizing control functions across multiple processing units, reducing the risk of total system failure. They enable improved real-time monitoring and control of complex industrial processes, ensuring higher efficiency and flexibility compared to embedded control systems. Your operations can benefit from easier maintenance, system upgrades, and integration with advanced analytics due to the modular nature of distributed control architectures.

Use Cases and Applications

Embedded control systems are widely used in consumer electronics, automotive systems, and medical devices where real-time, dedicated control tasks like sensor data processing and actuator control are essential. Distributed control systems excel in large-scale industrial automation, such as power plants and manufacturing processes, offering enhanced reliability and scalability by managing multiple interconnected controllers. Your choice depends on the complexity and spatial distribution of the control tasks, with embedded systems suited for localized control and distributed systems designed for coordinated, networked operations.

Factors to Consider When Choosing a Control System

Selecting between embedded and distributed control systems depends on factors such as system complexity, scalability requirements, and communication needs. Embedded control systems offer high reliability and low latency for dedicated tasks, while distributed control systems provide flexibility and fault tolerance through networked components. Considerations include cost, real-time performance, maintenance, and integration with existing infrastructure.

Future Trends in Control System Technology

Future trends in control system technology emphasize the integration of AI and machine learning algorithms in both embedded and distributed control systems to enhance adaptability and predictive maintenance. Embedded control systems are evolving with increased processing power and edge computing capabilities, enabling real-time data analysis and faster decision-making at the device level. Distributed control systems are trending towards enhanced connectivity through IoT and 5G networks, facilitating seamless communication, scalability, and collaborative control across complex industrial environments.

Embedded vs Distributed control system Infographic

libmatt.com

libmatt.com