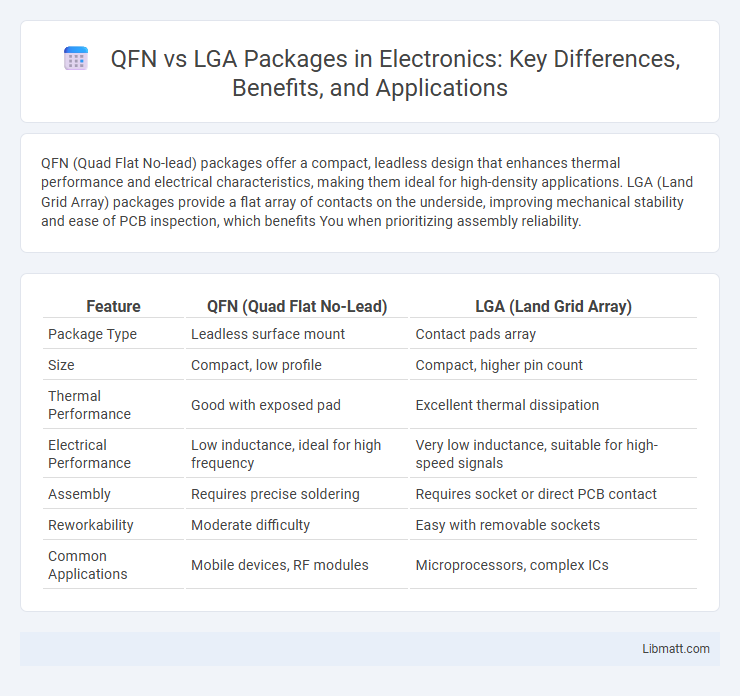

QFN (Quad Flat No-lead) packages offer a compact, leadless design that enhances thermal performance and electrical characteristics, making them ideal for high-density applications. LGA (Land Grid Array) packages provide a flat array of contacts on the underside, improving mechanical stability and ease of PCB inspection, which benefits You when prioritizing assembly reliability.

Table of Comparison

| Feature | QFN (Quad Flat No-Lead) | LGA (Land Grid Array) |

|---|---|---|

| Package Type | Leadless surface mount | Contact pads array |

| Size | Compact, low profile | Compact, higher pin count |

| Thermal Performance | Good with exposed pad | Excellent thermal dissipation |

| Electrical Performance | Low inductance, ideal for high frequency | Very low inductance, suitable for high-speed signals |

| Assembly | Requires precise soldering | Requires socket or direct PCB contact |

| Reworkability | Moderate difficulty | Easy with removable sockets |

| Common Applications | Mobile devices, RF modules | Microprocessors, complex ICs |

Introduction to QFN and LGA Packages

QFN (Quad Flat No-lead) and LGA (Land Grid Array) packages are popular surface-mount technologies used for integrated circuits, offering compact footprints and excellent electrical performance. QFN packages feature exposed pads on the underside for efficient heat dissipation and soldering, while LGA packages use a grid of flat contacts to ensure reliable connections with printed circuit boards. Understanding the differences between QFN and LGA packaging helps optimize your design for thermal management, signal integrity, and manufacturing processes.

Overview of QFN (Quad Flat No-Lead) Packages

QFN (Quad Flat No-Lead) packages feature a compact, leadless design ideal for high-frequency and space-constrained applications, providing excellent thermal and electrical performance. Their exposed copper pad on the bottom enhances heat dissipation and ensures reliable solder joints, making them suitable for power management and RF modules. You benefit from reduced package size and improved board-level reliability compared to traditional leaded packages.

Overview of LGA (Land Grid Array) Packages

LGA (Land Grid Array) packages feature an array of flat contact pads on the bottom of the package that directly interface with a printed circuit board (PCB) using a socket or soldering. This design enhances electrical performance and thermal dissipation, supporting high-density and high-frequency applications. You benefit from improved signal integrity and easier inspection compared to ball grid array alternatives, making LGA ideal for advanced microprocessors and RF devices.

Key Differences Between QFN and LGA

QFN (Quad Flat No-lead) packages feature exposed pads on the underside of the package, offering excellent thermal and electrical performance due to direct PCB contact, while LGA (Land Grid Array) packages utilize a grid of flat contacts that require precise soldering to PCB pads for signal integrity. QFN packages are typically smaller, with a lower profile and better heat dissipation, making them ideal for compact devices, whereas LGA packages provide higher pin counts and improved mechanical robustness suitable for complex, high-density applications. Your choice between QFN and LGA depends on factors such as PCB design constraints, thermal management needs, and manufacturing capabilities.

Electrical Performance: QFN vs LGA

QFN (Quad Flat No-Lead) packages offer lower parasitic inductance and capacitance due to their exposed pad design and shorter bond wires, resulting in superior high-frequency electrical performance compared to LGA (Land Grid Array) packages. LGA packages, while providing robust mechanical connections and better thermal dissipation, typically exhibit higher electrical resistance and inductance because of longer interconnect paths and solder bumps. Therefore, QFN is preferred for RF and high-speed applications where minimal signal loss and enhanced electrical performance are critical.

Mechanical Strength and Reliability

QFN (Quad Flat No-lead) packages offer superior mechanical strength due to their robust epoxy mold compound and exposed thermal pad, enhancing heat dissipation and structural integrity under thermal cycling. LGA (Land Grid Array) packages provide reliable solder joint connections with a flat contact surface that reduces mechanical stress during board flexing, improving long-term electrical performance. Both package types are engineered to withstand mechanical fatigue, but QFN typically excels in durability for high-stress environments, while LGA is preferred for applications requiring precise mechanical compliance.

Assembly and Soldering Considerations

QFN (Quad Flat No-Lead) packages require precise solder paste application and controlled reflow profiles to avoid solder bridging and ensure reliable thermal and electrical connections through their exposed pads. LGA (Land Grid Array) packages offer simplicity in alignment and inspection since the solder pads are on the PCB rather than the package, reducing the risk of tombstoning during assembly. Both package types benefit from optimized stencil design and accurate pick-and-place equipment to enhance solder joint quality and overall assembly yield.

Applications of QFN and LGA Packages

QFN packages are widely used in compact consumer electronics, wearable devices, and automotive sensors due to their excellent thermal performance and small footprint. LGA packages are preferred in high-performance computing, networking equipment, and telecommunications for their superior electrical connectivity and enhanced mechanical stability. Your choice between QFN and LGA will depend on the application's size constraints, thermal requirements, and signal integrity needs.

Cost Comparison and Availability

QFN (Quad Flat No-Lead) packages generally offer lower manufacturing costs due to simpler assembly processes and widespread availability in various standard sizes. LGA (Land Grid Array) packages tend to be more expensive because of their complex substrate requirements and precise underfill needs, which limit availability to specific high-performance applications. The broader market presence of QFN components results in more suppliers and lower lead times compared to the relatively niche and costlier LGA solutions.

Choosing the Right Package: QFN or LGA?

Choosing between QFN (Quad Flat No-lead) and LGA (Land Grid Array) packages depends on your application's size constraints, thermal management, and electrical performance needs. QFN offers excellent thermal dissipation and a compact footprint ideal for high-frequency applications, while LGA provides superior mechanical stability and easier inspection with its flat contact pads. Evaluating your priority for assembly processes, reliability, and signal integrity will guide you to select the package that best fits your design requirements.

QFN vs LGA package Infographic

libmatt.com

libmatt.com