Ball Grid Array (BGA) offers superior thermal performance and electrical efficiency due to its array of solder balls on the underside, enabling better heat dissipation and signal connections compared to the Quad Flat Package (QFP). Your choice between BGA and QFP depends on factors like PCB space, manufacturing complexity, and application requirements where BGA is preferred for high-density, high-performance designs while QFP suits simpler, cost-sensitive projects.

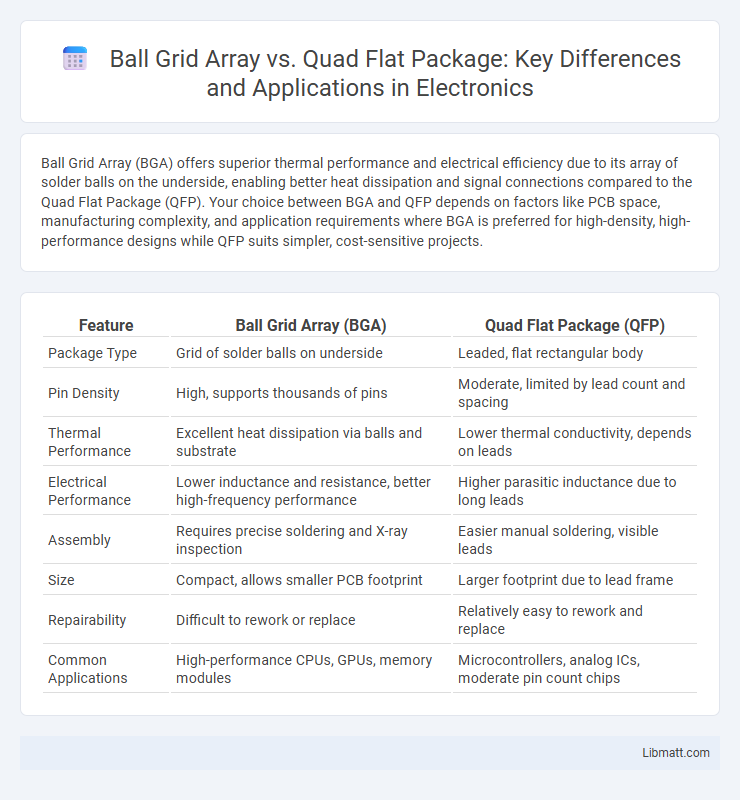

Table of Comparison

| Feature | Ball Grid Array (BGA) | Quad Flat Package (QFP) |

|---|---|---|

| Package Type | Grid of solder balls on underside | Leaded, flat rectangular body |

| Pin Density | High, supports thousands of pins | Moderate, limited by lead count and spacing |

| Thermal Performance | Excellent heat dissipation via balls and substrate | Lower thermal conductivity, depends on leads |

| Electrical Performance | Lower inductance and resistance, better high-frequency performance | Higher parasitic inductance due to long leads |

| Assembly | Requires precise soldering and X-ray inspection | Easier manual soldering, visible leads |

| Size | Compact, allows smaller PCB footprint | Larger footprint due to lead frame |

| Repairability | Difficult to rework or replace | Relatively easy to rework and replace |

| Common Applications | High-performance CPUs, GPUs, memory modules | Microcontrollers, analog ICs, moderate pin count chips |

Introduction to Ball Grid Array (BGA) and Quad Flat Package (QFP)

Ball Grid Array (BGA) is a surface-mount packaging technology characterized by an array of solder balls on the underside of the chip, providing excellent electrical performance and heat dissipation for high-density applications. Quad Flat Package (QFP) features flat leads extending from all four sides of the package, offering ease of inspection and soldering, commonly used in moderate pin count devices. Understanding the differences between BGA and QFP helps you select the appropriate package for your electronic design, balancing considerations of space, thermal management, and manufacturing complexity.

Key Differences Between BGA and QFP

Ball Grid Array (BGA) features solder balls on the underside for connection, enabling higher pin counts and better heat dissipation compared to the Quad Flat Package (QFP), which uses gull-wing leads around the edges. BGA offers improved electrical performance and reduced inductance, making it ideal for high-frequency applications, while QFP is easier to inspect and rework due to its visible leads. Understanding these key differences can help you select the appropriate package for your PCB design needs.

Physical Structure and Design Comparison

Ball Grid Array (BGA) features a grid of solder balls on the underside, enabling a smaller footprint and better heat dissipation compared to the Quad Flat Package (QFP), which has leads extending from the package edges. BGA's design supports higher pin counts and improved electrical performance, while QFP's gull-wing leads simplify visual inspection and prototyping. Your choice depends on requirements for thermal management, space constraints, and assembly complexity.

Electrical Performance: BGA vs QFP

Ball Grid Array (BGA) packages offer superior electrical performance compared to Quad Flat Package (QFP) due to shorter lead lengths and reduced parasitic inductance, resulting in lower signal distortion and improved high-frequency operation. The BGA's array of solder balls under the package provides enhanced thermal dissipation and better ground and power integrity, crucial for high-speed, high-density circuits. In contrast, QFPs have longer leads that increase inductance and resistance, limiting their effectiveness in high-frequency or high-performance applications.

Assembly and Soldering Techniques

Ball Grid Array (BGA) packages employ solder balls beneath the component for assembly, providing superior thermal and electrical performance due to their uniform heat distribution and shorter interconnections. Quad Flat Package (QFP) devices use gull-wing leads soldered on PCB pads, requiring precise alignment and careful soldering to avoid bridging or cold joints. Your choice between BGA and QFP will impact the soldering technique, with BGA demanding specialized reflow processes and X-ray inspection for quality assurance, whereas QFP allows for more conventional wave soldering methods and optical inspection.

Reliability and Durability Considerations

Ball Grid Array (BGA) packages offer superior reliability due to their evenly distributed solder balls, which reduce mechanical stress and improve heat dissipation compared to Quad Flat Package (QFP) leads that are more prone to bending and cracking. BGAs provide enhanced durability in high-vibration environments, making them ideal for applications requiring long-term performance and minimal failure rates. Your choice should consider the specific operating conditions, as BGAs handle thermal cycling and mechanical fatigue more effectively than QFPs.

Thermal Management: Which is Better?

Ball Grid Array (BGA) packages offer superior thermal management compared to Quad Flat Packages (QFP) due to their enhanced heat dissipation capabilities through solder balls directly connected to the PCB, enabling efficient thermal conduction. BGA's lower thermal resistance supports higher power devices by facilitating better heat spread and reducing hotspots. In contrast, QFPs rely on lead frames with limited thermal pathways, often resulting in less effective heat dissipation and higher operating temperatures.

Cost Implications of BGA and QFP

Ball Grid Array (BGA) packages generally have higher initial manufacturing costs due to complex assembly processes and specialized equipment requirements, but they offer cost savings in high-volume production through improved reliability and reduced board space. Quad Flat Package (QFP) designs typically incur lower upfront costs with simpler assembly and inspection methods but may lead to increased expenses in advanced applications because of larger PCB real estate and potential thermal management challenges. Choosing between BGA and QFP involves balancing these cost factors against production scale, performance needs, and long-term reliability considerations.

Applications and Industry Use Cases

Ball Grid Array (BGA) packages are widely used in high-performance computing, mobile devices, and aerospace due to their superior thermal dissipation and reliable electrical connections, making them ideal for complex integrated circuits like GPUs and CPUs. Quad Flat Package (QFP) finds its applications primarily in consumer electronics, automotive control systems, and industrial devices where ease of inspection and lower manufacturing costs are crucial. Your choice between BGA and QFP should consider the specific performance requirements and assembly constraints of your target industry or application.

Choosing the Right Package: BGA or QFP?

Choosing the right package between Ball Grid Array (BGA) and Quad Flat Package (QFP) depends on factors like board space, thermal performance, and assembly complexity. BGA offers superior electrical performance with higher pin density and better heat dissipation, making it ideal for compact, high-speed applications. QFP provides easier visual inspection and reworkability, suitable for designs requiring lower cost and simpler manufacturing processes.

Ball Grid Array vs Quad Flat Package Infographic

libmatt.com

libmatt.com