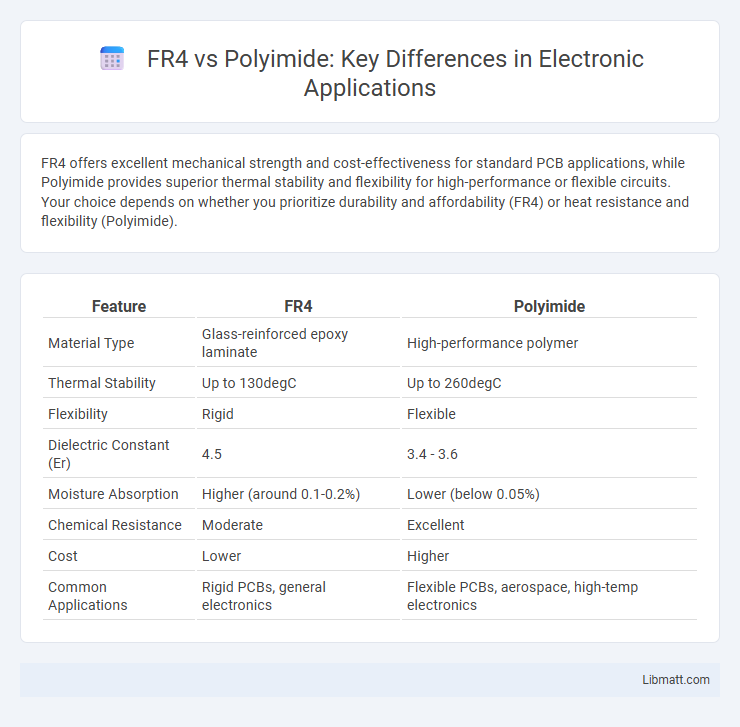

FR4 offers excellent mechanical strength and cost-effectiveness for standard PCB applications, while Polyimide provides superior thermal stability and flexibility for high-performance or flexible circuits. Your choice depends on whether you prioritize durability and affordability (FR4) or heat resistance and flexibility (Polyimide).

Table of Comparison

| Feature | FR4 | Polyimide |

|---|---|---|

| Material Type | Glass-reinforced epoxy laminate | High-performance polymer |

| Thermal Stability | Up to 130degC | Up to 260degC |

| Flexibility | Rigid | Flexible |

| Dielectric Constant (Er) | 4.5 | 3.4 - 3.6 |

| Moisture Absorption | Higher (around 0.1-0.2%) | Lower (below 0.05%) |

| Chemical Resistance | Moderate | Excellent |

| Cost | Lower | Higher |

| Common Applications | Rigid PCBs, general electronics | Flexible PCBs, aerospace, high-temp electronics |

Introduction to FR4 and Polyimide

FR4 is a widely used fiberglass-reinforced epoxy laminate known for its excellent mechanical strength, electrical insulation, and flame resistance, making it a standard material in printed circuit boards (PCBs). Polyimide is a high-performance polymer characterized by exceptional thermal stability, flexibility, and chemical resistance, commonly utilized in flexible PCBs and high-temperature applications. Both materials serve distinct purposes in electronics manufacturing, with FR4 excelling in rigid board construction and Polyimide offering advantages in environments requiring flexibility and heat endurance.

Material Composition and Structure

FR4 is a composite material made of woven fiberglass cloth and epoxy resin, offering high mechanical strength and excellent electrical insulation. Polyimide consists of polymer chains known for their thermal stability, flexibility, and resistance to chemicals and radiation. Choosing between FR4 and polyimide depends on your application's requirements for rigidity, temperature endurance, and dielectric properties.

Thermal Performance Comparison

FR4 offers a glass transition temperature (Tg) around 130-140degC, making it suitable for standard electronic applications, whereas Polyimide boasts a higher Tg typically above 250degC, enabling superior thermal stability in high-temperature environments. Polyimide's enhanced thermal performance ensures better resistance to thermal cycling and mechanical stress, extending the reliability of your flexible printed circuit boards under demanding conditions. Choosing Polyimide over FR4 improves heat dissipation and reduces the risk of material degradation during intense thermal exposure.

Mechanical Strength and Flexibility

FR4 offers superior mechanical strength with a rigid fiberglass epoxy resin structure, making it ideal for robust, high-stress applications. Polyimide excels in flexibility and thermal stability, allowing your circuits to withstand bending and flexing without compromising integrity. Choosing between them depends on whether your design prioritizes durability or adaptable flexibility.

Electrical Properties Analysis

FR4 exhibits a dielectric constant (Dk) around 4.5, providing stable electrical insulation and moderate signal integrity, while polyimide offers a lower dielectric constant typically near 3.4, enhancing high-frequency signal transmission and reducing dielectric loss. Polyimide's superior thermal stability allows it to maintain consistent electrical properties under extreme temperature variations, unlike FR4, which may experience property degradation when exposed to high heat. Dielectric loss tangent values are generally lower in polyimide, making it preferable for applications requiring minimal signal attenuation and improved high-speed performance.

Cost Differences and Budget Considerations

FR4 is significantly more cost-effective compared to polyimide, making it a preferred choice for budget-sensitive projects and high-volume production runs. Polyimide offers superior thermal stability and flexibility, but these advantages come with a higher price tag that can impact overall project budgets. Careful assessment of application requirements and cost constraints is essential to balance performance needs against material expenses.

Applications in Electronics

FR4 is widely used in printed circuit boards (PCBs) for conventional electronics due to its excellent mechanical strength, electrical insulation, and cost-effectiveness. Polyimide is preferred in high-performance and flexible electronics applications, offering superior thermal stability, chemical resistance, and flexibility for advanced wearable devices and aerospace components. Choosing between FR4 and polyimide depends on your application's thermal requirements, mechanical flexibility, and environmental conditions.

Manufacturing Process and Compatibility

FR4 is a widely used fiberglass epoxy laminate with a well-established manufacturing process involving fiberglass cloth impregnated with epoxy resin and cured under heat and pressure, ensuring excellent mechanical stability and cost-effectiveness for standard PCB applications. Polyimide, on the other hand, undergoes a more complex manufacturing process that includes using high-temperature-resistant polymer films, making it compatible with flexible, high-performance electronic substrates requiring superior thermal stability and chemical resistance. Your choice between FR4 and Polyimide hinges on the specific manufacturing requirements and compatibility with operating environments, especially when flexibility and high-temperature tolerance are critical.

Durability and Environmental Resistance

FR4 offers excellent durability with high mechanical strength and strong resistance to moisture, making it ideal for standard electronic applications. Polyimide, known for superior thermal stability and exceptional chemical resistance, outperforms FR4 in extreme temperature and harsh chemical environments. Polyimide's flexibility and endurance against thermal cycling enhance its environmental resistance, extending the lifespan of flexible and high-reliability circuits.

Choosing Between FR4 and Polyimide

When choosing between FR4 and polyimide, consider your application's thermal and mechanical requirements; FR4 offers cost-effective, rigid support ideal for standard circuit boards, while polyimide excels in high-temperature flexibility and chemical resistance. Your choice impacts device durability and performance, with polyimide preferred in aerospace or flexible electronics and FR4 suitable for most consumer electronics. Evaluate factors such as operating temperature, flexibility needs, and budget to determine the optimal substrate material.

FR4 vs Polyimide Infographic

libmatt.com

libmatt.com