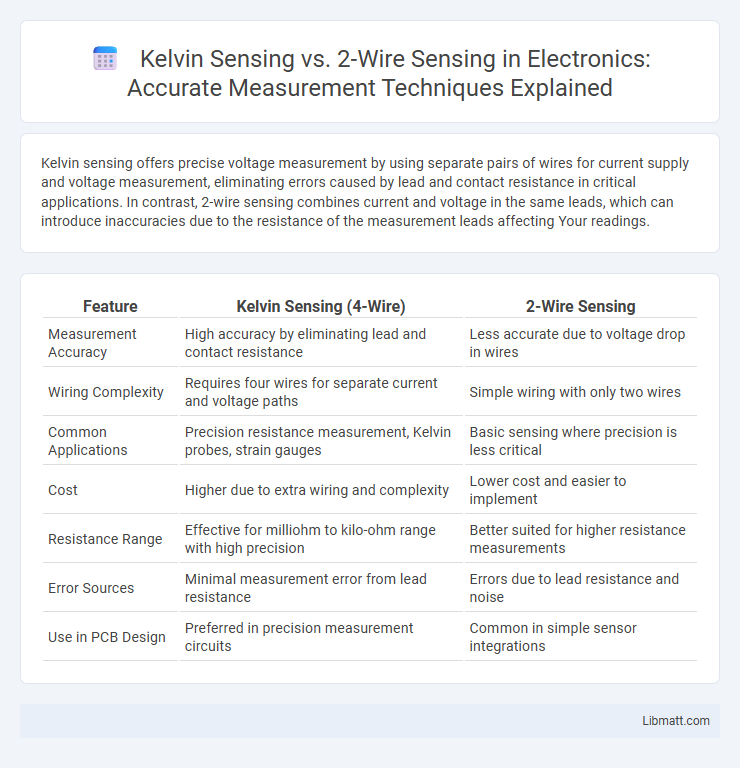

Kelvin sensing offers precise voltage measurement by using separate pairs of wires for current supply and voltage measurement, eliminating errors caused by lead and contact resistance in critical applications. In contrast, 2-wire sensing combines current and voltage in the same leads, which can introduce inaccuracies due to the resistance of the measurement leads affecting Your readings.

Table of Comparison

| Feature | Kelvin Sensing (4-Wire) | 2-Wire Sensing |

|---|---|---|

| Measurement Accuracy | High accuracy by eliminating lead and contact resistance | Less accurate due to voltage drop in wires |

| Wiring Complexity | Requires four wires for separate current and voltage paths | Simple wiring with only two wires |

| Common Applications | Precision resistance measurement, Kelvin probes, strain gauges | Basic sensing where precision is less critical |

| Cost | Higher due to extra wiring and complexity | Lower cost and easier to implement |

| Resistance Range | Effective for milliohm to kilo-ohm range with high precision | Better suited for higher resistance measurements |

| Error Sources | Minimal measurement error from lead resistance | Errors due to lead resistance and noise |

| Use in PCB Design | Preferred in precision measurement circuits | Common in simple sensor integrations |

Introduction to Kelvin Sensing and 2-Wire Sensing

Kelvin sensing, also known as 4-wire sensing, measures voltage directly at the load to eliminate errors caused by lead and contact resistances, providing highly accurate resistance measurements. In contrast, 2-wire sensing uses the same pair of wires for current supply and voltage measurement, making it simpler but less precise due to voltage drops in the leads. Your choice between Kelvin and 2-wire sensing depends on the need for precision, especially in low-resistance applications where Kelvin sensing offers superior accuracy.

What is Kelvin Sensing?

Kelvin sensing is a precise electrical measurement technique that eliminates the effects of lead and contact resistance by using separate pairs of current-carrying and voltage-sensing electrodes. Unlike 2-wire sensing, which combines current and voltage paths and can introduce significant measurement errors in low-resistance components, Kelvin sensing ensures accurate readings by isolating the voltage measurement from the current flow. Your measurements benefit from improved accuracy and reliability, especially in applications involving small resistances or sensitive electronic components.

What is 2-Wire Sensing?

2-wire sensing measures voltage and current through the same pair of wires, making it simpler but less accurate due to voltage drop caused by wire resistance. Kelvin sensing, or 4-wire sensing, uses separate pairs for current and voltage measurements, eliminating errors from lead resistance. You can achieve higher precision in low-resistance measurements with Kelvin sensing compared to the more basic 2-wire method.

Key Differences Between Kelvin and 2-Wire Sensing

Kelvin sensing uses four wires to eliminate the effect of lead resistance, ensuring highly accurate voltage measurements by separating current-carrying and voltage-sensing pathways. In contrast, 2-wire sensing combines current and voltage measurement in the same leads, resulting in potential measurement errors due to voltage drops across the leads. The key difference lies in Kelvin sensing's ability to provide precise readings in low-resistance applications, whereas 2-wire sensing is simpler but less accurate.

Pros and Cons of Kelvin Sensing

Kelvin sensing, also known as 4-wire sensing, offers superior accuracy by eliminating the effect of lead and contact resistance, making it ideal for precise low-resistance measurements in industrial and laboratory applications. Its main disadvantage is the increased complexity and cost due to additional wiring and connectors compared to 2-wire sensing, which is simpler but more susceptible to measurement errors caused by resistive losses in the leads. You benefit from Kelvin sensing when measurement precision is critical, despite the trade-off in installation effort and expense.

Pros and Cons of 2-Wire Sensing

2-wire sensing offers simplicity and cost-effectiveness by using only two conductors for both current supply and voltage measurement but suffers from inaccuracies due to voltage drops along the wires, particularly in longer distances or higher currents. This method is suitable for short runs with low current, where errors remain minimal, but becomes unreliable in precision applications where exact voltage measurement at the load is critical. The lack of separate sense lines in 2-wire sensing limits its ability to compensate for lead resistance, resulting in potential measurement errors that impact control and performance.

Application Scenarios: When to Use Each Method

Kelvin sensing is ideal for high-precision measurements in low-resistance applications, such as PCB trace resistance testing and strain gauge sensors, where eliminating lead and contact resistance is critical. Two-wire sensing suits general-purpose measurements with higher resistance values or less stringent accuracy requirements, like basic temperature sensing or battery voltage monitoring. Your choice depends on the need for accuracy and resistance levels in the specific application scenario.

Accuracy Comparisons: Kelvin vs 2-Wire Sensing

Kelvin sensing offers superior accuracy compared to 2-wire sensing by eliminating the effects of lead and contact resistances, which can introduce significant measurement errors in 2-wire configurations. The 4-wire Kelvin method uses separate pairs of current-carrying and voltage-sensing leads, ensuring that voltage measurement is unaffected by the resistance of the leads. As a result, Kelvin sensing is preferred in high-precision applications such as resistance measurements below 1 ohm, where its accuracy can be within micro-ohm ranges.

Implementation Challenges and Solutions

Kelvin sensing uses four wires to accurately measure voltage directly at the load, minimizing the effects of lead resistance and improving precision, while 2-wire sensing relies on the combined voltage drop across the load and leads, causing measurement errors in high-current or long-wire applications. Implementation challenges of Kelvin sensing include increased wiring complexity and the need for precise connection points, which require careful layout and insulation design to avoid noise and interference. Solutions involve using dedicated Kelvin sensing connectors, twisted-pair wiring, and careful PCB trace routing to ensure stable, accurate voltage readings in sensitive electronic systems.

Conclusion: Choosing the Right Sensing Technique

Kelvin sensing provides superior accuracy by eliminating the effects of lead and contact resistance, making it ideal for precise low-resistance measurements in sensitive applications. In contrast, 2-wire sensing is simpler and more cost-effective but can introduce significant measurement errors in low-resistance or high-precision scenarios. Selecting the right sensing technique depends on the required measurement accuracy, application complexity, and budget constraints.

Kelvin sensing vs 2-wire sensing Infographic

libmatt.com

libmatt.com