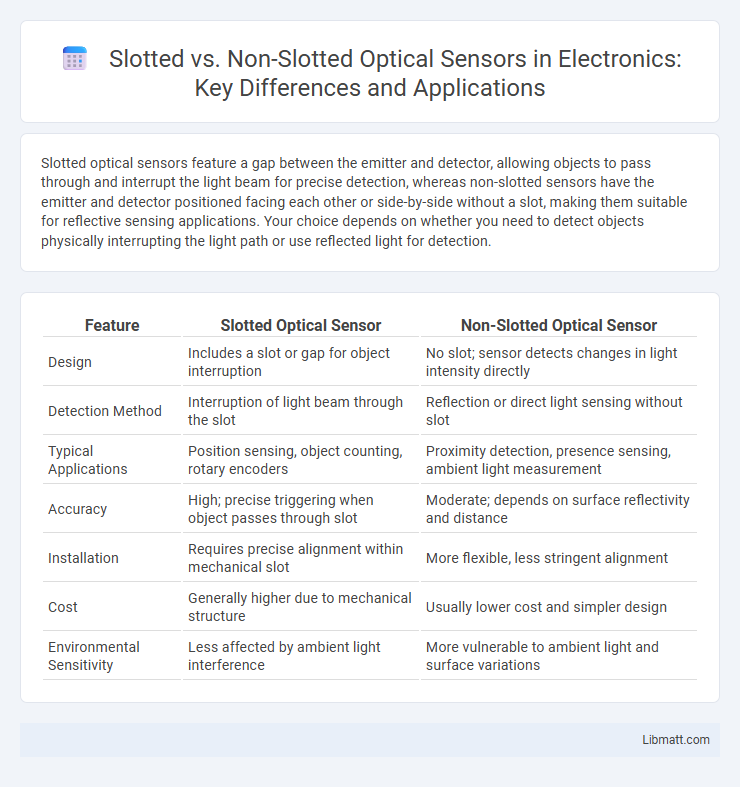

Slotted optical sensors feature a gap between the emitter and detector, allowing objects to pass through and interrupt the light beam for precise detection, whereas non-slotted sensors have the emitter and detector positioned facing each other or side-by-side without a slot, making them suitable for reflective sensing applications. Your choice depends on whether you need to detect objects physically interrupting the light path or use reflected light for detection.

Table of Comparison

| Feature | Slotted Optical Sensor | Non-Slotted Optical Sensor |

|---|---|---|

| Design | Includes a slot or gap for object interruption | No slot; sensor detects changes in light intensity directly |

| Detection Method | Interruption of light beam through the slot | Reflection or direct light sensing without slot |

| Typical Applications | Position sensing, object counting, rotary encoders | Proximity detection, presence sensing, ambient light measurement |

| Accuracy | High; precise triggering when object passes through slot | Moderate; depends on surface reflectivity and distance |

| Installation | Requires precise alignment within mechanical slot | More flexible, less stringent alignment |

| Cost | Generally higher due to mechanical structure | Usually lower cost and simpler design |

| Environmental Sensitivity | Less affected by ambient light interference | More vulnerable to ambient light and surface variations |

Introduction to Optical Sensors

Optical sensors detect light changes to measure physical properties like distance or presence, with slotted and non-slotted types serving distinct applications. Slotted optical sensors feature a gap where an object interrupts the light beam, enabling precise detection of object position or movement. Non-slotted sensors rely on reflective or transmissive detection without a gap, ideal for broader sensing tasks such as proximity or color detection.

Overview of Slotted Optical Sensors

Slotted optical sensors, also known as fork sensors, consist of an emitter and detector housed in a U-shaped casing that allows an object to pass through the slot, interrupting the light beam to detect its presence or position. These sensors are widely used for object detection, counting, and position sensing in industrial automation due to their compact design and precise detection capabilities. Their configuration enables easy alignment and effective detection of small or opaque objects without the need for reflective surfaces.

Overview of Non-slotted Optical Sensors

Non-slotted optical sensors operate without a physical slot or gap, relying instead on the direct interruption or reflection of light to detect objects. These sensors are commonly used in applications requiring simple presence or proximity detection with higher durability since they have fewer moving parts. Your choice of a non-slotted optical sensor can enhance reliability in environments where dust or debris might obstruct slotted sensor slots.

Working Principles: Slotted vs Non-slotted

Slotted optical sensors detect objects by interrupting a light beam between an emitter and a receiver within a physical slot, making them highly effective for edge detection and position sensing. Non-slotted optical sensors, however, rely on reflective principles where the emitter projects light onto a surface and the receiver detects the reflected signal, suitable for detecting surface presence or color changes. Your choice between slotted and non-slotted sensors depends on the specific application requirements related to object detection and sensor placement.

Key Applications of Slotted Sensors

Slotted optical sensors are widely used in industrial automation for detecting the presence or absence of objects within the sensor slot, making them ideal for applications like paper edge detection, object counting on conveyor belts, and position sensing in printers and copiers. These sensors provide reliable, high-speed detection by utilizing an LED and phototransistor aligned opposite each other with a slot in between, ensuring precise object interruption detection. Your manufacturing or quality control processes benefit from the accuracy and simplicity of slotted sensors when identifying item positions or ensuring consistent product flow.

Common Uses of Non-slotted Sensors

Non-slotted optical sensors are commonly used in object detection, proximity sensing, and industrial automation where physical interruption is not feasible or required. These sensors are ideal for applications like conveyor belt monitoring, counting items passing through a designated area, and liquid level detection. Their design allows non-contact sensing in environments where dust, dirt, or alignment issues could affect slotted sensor performance.

Performance Comparison: Accuracy and Speed

Slotted optical sensors offer higher accuracy by providing precise alignment through a physical slot that guides the target, minimizing detection errors caused by misalignment or ambient light interference. Non-slotted optical sensors rely on reflective detection which can result in slightly lower accuracy but offer faster response times due to simpler signal processing mechanisms. The choice between slotted and non-slotted sensors depends on application-specific requirements for detection speed versus positional precision.

Installation and Maintenance Considerations

Slotted optical sensors simplify installation by allowing easy alignment of the target object within the slot, reducing the need for precise positioning and minimizing setup time. Non-slotted sensors require more careful alignment and stable mounting because the sensor and emitter are housed separately, increasing installation complexity. Maintenance for slotted sensors is generally easier since dirt and debris inside the slot can be more accessible for cleaning, whereas non-slotted sensors might need more frequent recalibration to maintain sensor accuracy.

Cost and Availability Analysis

Slotted optical sensors generally cost more due to their intricate designs and higher precision components, making them less widely available than non-slotted variants. Non-slotted optical sensors offer a cost-effective solution with broader availability in the market, largely due to simpler construction and higher production volumes. The choice between the two hinges on balancing budget constraints with specific application requirements for accuracy and sensor placement.

Choosing the Right Optical Sensor for Your Needs

Select a slotted optical sensor for precise object detection where an interrupt in the light beam is required, ideal for applications like rotary encoders and position sensing. Non-slotted optical sensors work best for proximity detection without physical interruption, suitable for material presence or color detection tasks. Evaluate factors like sensing distance, environmental conditions, and speed requirements to determine the optimal sensor type for your specific application.

Slotted vs Non-slotted optical sensor Infographic

libmatt.com

libmatt.com