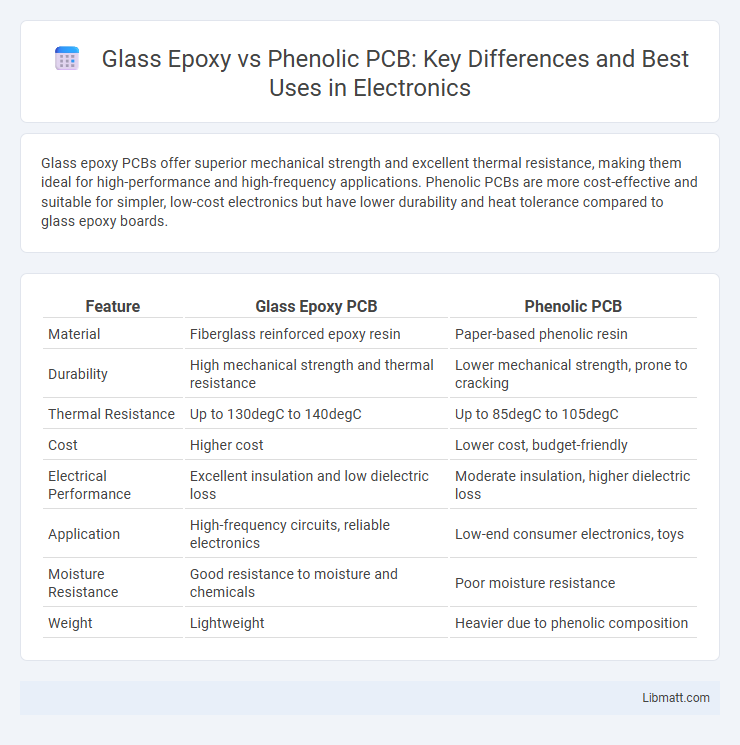

Glass epoxy PCBs offer superior mechanical strength and excellent thermal resistance, making them ideal for high-performance and high-frequency applications. Phenolic PCBs are more cost-effective and suitable for simpler, low-cost electronics but have lower durability and heat tolerance compared to glass epoxy boards.

Table of Comparison

| Feature | Glass Epoxy PCB | Phenolic PCB |

|---|---|---|

| Material | Fiberglass reinforced epoxy resin | Paper-based phenolic resin |

| Durability | High mechanical strength and thermal resistance | Lower mechanical strength, prone to cracking |

| Thermal Resistance | Up to 130degC to 140degC | Up to 85degC to 105degC |

| Cost | Higher cost | Lower cost, budget-friendly |

| Electrical Performance | Excellent insulation and low dielectric loss | Moderate insulation, higher dielectric loss |

| Application | High-frequency circuits, reliable electronics | Low-end consumer electronics, toys |

| Moisture Resistance | Good resistance to moisture and chemicals | Poor moisture resistance |

| Weight | Lightweight | Heavier due to phenolic composition |

Introduction to PCB Materials

Glass epoxy and phenolic are two primary PCB materials with distinct properties affecting performance and cost. Glass epoxy, known for its excellent thermal stability and mechanical strength, is commonly used in high-frequency and high-reliability applications. Phenolic, a cheaper alternative, offers moderate durability but lower heat resistance, making it suitable for simple, low-cost electronics where thermal demands are minimal.

Overview of Glass Epoxy PCBs

Glass epoxy PCBs, also known as FR-4 boards, consist of woven fiberglass cloth fused with epoxy resin, offering excellent mechanical strength and electrical insulation. These printed circuit boards provide high resistance to moisture, heat, and chemicals, making them ideal for a wide range of electronic applications from consumer devices to industrial equipment. Your electronics benefit from their durability and reliable performance in demanding environments.

Overview of Phenolic PCBs

Phenolic PCBs are made from a composite material combining paper or fabric with phenolic resin, resulting in a cost-effective and lightweight printed circuit board. These boards offer moderate mechanical strength and electrical insulation, making them suitable for low-frequency and consumer electronics applications. Phenolic PCBs typically have lower thermal stability and durability compared to glass epoxy PCBs, limiting their use in high-performance or high-temperature environments.

Material Composition Comparison

Glass epoxy PCBs consist of fiberglass cloth combined with epoxy resin, providing high mechanical strength and excellent electrical insulation. Phenolic PCBs use a composite of paper and phenolic resin, which results in a more affordable but less durable and heat-resistant board. The superior chemical stability and moisture resistance of glass epoxy make it ideal for high-performance electronic applications compared to the phenolic alternative.

Mechanical Strength and Durability

Glass epoxy PCBs exhibit superior mechanical strength and durability due to their reinforced fiberglass core, which provides enhanced resistance to bending, impact, and thermal stress. Phenolic PCBs, made from cellulose-based materials, offer lower mechanical robustness and are more prone to warping and cracking under mechanical strain or high humidity. Your choice of PCB material significantly affects the longevity and performance of electronic devices, especially in demanding mechanical environments.

Thermal and Electrical Performance

Glass epoxy PCBs exhibit superior thermal stability with a higher glass transition temperature (Tg) typically ranging from 130degC to 180degC, enabling reliable performance under increased heat conditions. Phenolic PCBs have lower thermal resistance, with Tg around 90degC, making them less suitable for high-temperature applications but often more cost-effective. Electrically, glass epoxy offers excellent insulation and lower dielectric loss, enhancing signal integrity in high-frequency circuits compared to phenolic boards, which exhibit higher dielectric constant and loss, limiting their use in advanced electronics.

Cost Efficiency and Affordability

Glass epoxy PCBs offer superior cost efficiency due to their widespread availability and lower material costs compared to phenolic PCBs, making them ideal for high-volume production. Phenolic PCBs, while more affordable upfront, tend to degrade faster and may require frequent replacements, increasing long-term expenses. Your choice depends on balancing initial affordability with durability and lifecycle costs.

Common Applications in Electronics

Glass epoxy PCBs are extensively used in high-frequency electronics, telecommunications, and computer hardware due to their excellent electrical insulation, mechanical strength, and heat resistance. Phenolic PCBs are preferred in low-cost, consumer electronic devices such as calculators and toys where moderate heat resistance and durability suffice. Both materials serve distinct application markets driven by performance requirements and budget constraints, with glass epoxy dominating high-performance sectors.

Environmental Impact and Lifespan

Glass epoxy PCBs offer superior environmental resistance and longer lifespan due to their strong thermal stability and moisture resistance, making them ideal for harsh conditions. Phenolic PCBs have a shorter lifespan and higher environmental impact because they absorb moisture and degrade faster under heat and humidity. Choosing glass epoxy enhances your device's durability while reducing electronic waste over time.

Choosing the Right PCB Material

Choosing the right PCB material significantly impacts your project's durability and performance, with Glass Epoxy offering superior thermal stability and electrical insulation for high-frequency applications. Phenolic PCB, while more cost-effective, provides less mechanical strength and is better suited for low-cost, low-power devices. Evaluating your product's environmental exposure and electrical requirements ensures you select the most appropriate substrate for long-term reliability.

Glass Epoxy vs Phenolic PCB Infographic

libmatt.com

libmatt.com