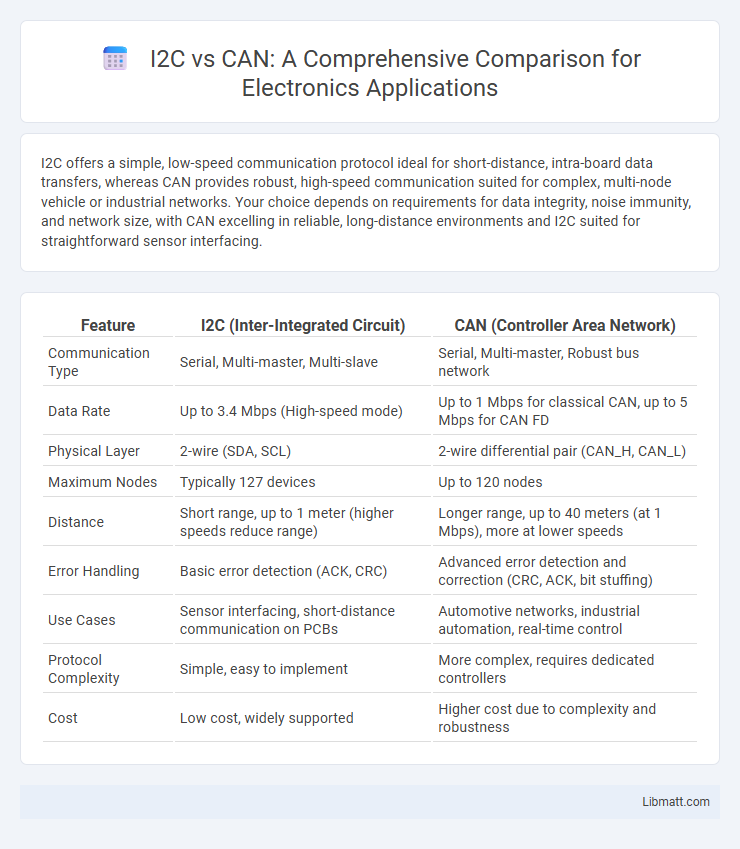

I2C offers a simple, low-speed communication protocol ideal for short-distance, intra-board data transfers, whereas CAN provides robust, high-speed communication suited for complex, multi-node vehicle or industrial networks. Your choice depends on requirements for data integrity, noise immunity, and network size, with CAN excelling in reliable, long-distance environments and I2C suited for straightforward sensor interfacing.

Table of Comparison

| Feature | I2C (Inter-Integrated Circuit) | CAN (Controller Area Network) |

|---|---|---|

| Communication Type | Serial, Multi-master, Multi-slave | Serial, Multi-master, Robust bus network |

| Data Rate | Up to 3.4 Mbps (High-speed mode) | Up to 1 Mbps for classical CAN, up to 5 Mbps for CAN FD |

| Physical Layer | 2-wire (SDA, SCL) | 2-wire differential pair (CAN_H, CAN_L) |

| Maximum Nodes | Typically 127 devices | Up to 120 nodes |

| Distance | Short range, up to 1 meter (higher speeds reduce range) | Longer range, up to 40 meters (at 1 Mbps), more at lower speeds |

| Error Handling | Basic error detection (ACK, CRC) | Advanced error detection and correction (CRC, ACK, bit stuffing) |

| Use Cases | Sensor interfacing, short-distance communication on PCBs | Automotive networks, industrial automation, real-time control |

| Protocol Complexity | Simple, easy to implement | More complex, requires dedicated controllers |

| Cost | Low cost, widely supported | Higher cost due to complexity and robustness |

Introduction to I2C and CAN Protocols

I2C (Inter-Integrated Circuit) is a multi-master, multi-slave, serial communication protocol primarily used for short-distance communication between microcontrollers and peripherals within embedded systems. CAN (Controller Area Network) is a robust vehicle bus standard designed for reliable communication in automotive and industrial environments, supporting error detection and fault confinement. Both protocols offer efficient data transfer but differ in complexity, speed, and application scope, with I2C suited for simple, low-speed tasks and CAN optimized for high-speed, fault-tolerant networks.

Key Features of I2C Communication

I2C communication features a a multi-master, multi-slave architecture using just two bidirectional lines: the Serial Data Line (SDA) and Serial Clock Line (SCL), enabling efficient short-distance data transfer between microcontrollers and peripherals. It supports speed modes from 100 kbps (standard) up to 3.4 Mbps (high-speed), providing flexibility for various embedded system applications. Your choice of I2C is ideal for simple, low-speed sensor interfacing where minimal wiring and easy synchronization matter most.

Essential Characteristics of CAN Bus

The CAN bus features a multi-master, message-oriented protocol designed for robust communication in automotive and industrial environments, supporting speeds up to 1 Mbps and real-time data exchange through prioritized message arbitration. Its differential signaling ensures noise immunity and reliability over long distances, making it ideal for controlling complex systems. You can rely on CAN's error detection and fault confinement mechanisms to maintain high data integrity and network stability.

Speed and Data Rate Comparison

I2C typically operates at speeds up to 400 kbps in Fast Mode, with some variants reaching 3.4 Mbps in High-Speed Mode, while CAN supports data rates up to 1 Mbps for Classical CAN and 5 Mbps for CAN FD. In applications where high-speed and robust data transmission over longer distances is crucial, CAN provides superior performance compared to I2C. Your choice between I2C and CAN should consider these speed and data rate differences based on the specific demands of your communication system.

Network Topology and Scalability

I2C employs a simple bus topology ideal for short-distance communication with limited devices due to its single-master multi-slave configuration, constraining scalability. CAN utilizes a multi-master bus topology with differential signaling, supporting robust, long-distance communication and easily scalable networks of up to 30 or more nodes in automotive and industrial environments. The flexibility of CAN's topology and error-handling mechanisms significantly enhance scalability for complex distributed control systems compared to I2C.

Communication Reliability and Error Handling

I2C communication offers basic error detection through acknowledgment bits but lacks advanced error correction, making it less reliable in noisy environments compared to CAN. CAN protocol integrates robust error handling with automatic retransmission and error confinement features, ensuring high communication reliability in automotive and industrial applications. Your choice between I2C and CAN should consider the criticality of error management and network robustness required for your system.

Power Consumption Considerations

I2C typically consumes less power than CAN due to its simpler protocol and lower data rates, making it ideal for battery-powered or energy-sensitive applications. CAN's higher power consumption results from its robust error-checking and longer communication distances, which require stronger signal driving and transceivers. Your choice depends on balancing power efficiency with communication reliability and range requirements.

Typical Applications of I2C and CAN

I2C is commonly used in low-speed communication between microcontrollers and peripheral devices such as sensors, EEPROMs, and real-time clocks in consumer electronics and embedded systems. CAN is widely employed in automotive and industrial environments for robust, high-speed communication among electronic control units (ECUs) and devices requiring fault-tolerant data exchange. Your choice between I2C and CAN depends on the need for short-range, simple data transfer or long-distance, reliable communication with error handling.

Hardware and Implementation Costs

I2C (Inter-Integrated Circuit) typically incurs lower hardware and implementation costs due to its simpler two-wire design and minimal component requirements, making it ideal for short-distance communication within a single device or between nearby components. CAN (Controller Area Network), designed for robust automotive and industrial applications, requires more complex transceivers and controllers, leading to higher hardware costs but offering superior noise immunity and long-distance capabilities. Implementation expenses for CAN also include more intricate software protocols and diagnostic tools, whereas I2C's straightforward protocol reduces development time and associated costs.

Choosing the Right Protocol: I2C vs CAN

Choosing between I2C and CAN depends on your application's requirements for communication speed, distance, and complexity. I2C is suitable for short-distance, low-speed communication within devices due to its simple two-wire interface and ease of implementation. CAN offers robust, high-speed communication over longer distances with error detection and fault tolerance, making it ideal for automotive and industrial environments.

I2C vs CAN Infographic

libmatt.com

libmatt.com