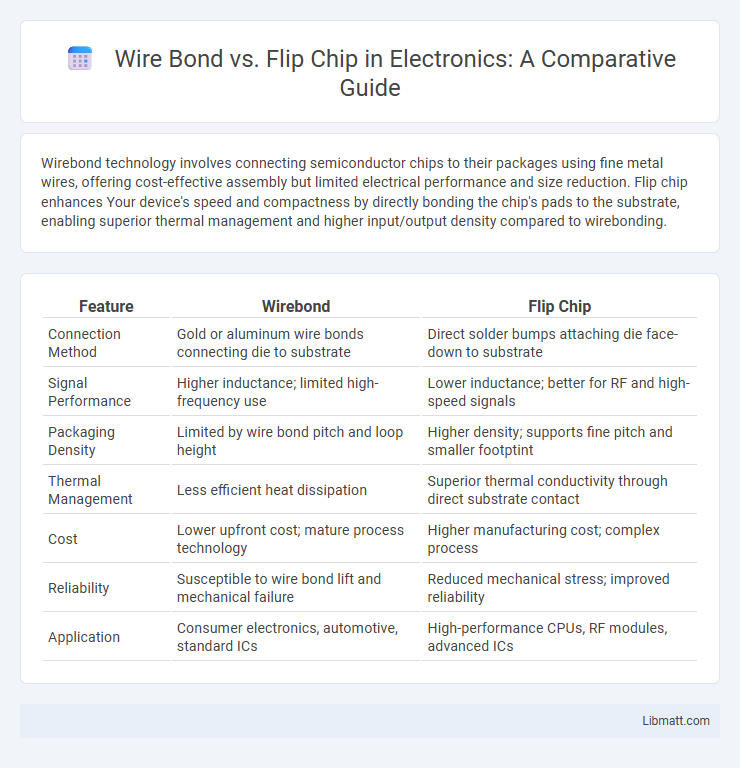

Wirebond technology involves connecting semiconductor chips to their packages using fine metal wires, offering cost-effective assembly but limited electrical performance and size reduction. Flip chip enhances Your device's speed and compactness by directly bonding the chip's pads to the substrate, enabling superior thermal management and higher input/output density compared to wirebonding.

Table of Comparison

| Feature | Wirebond | Flip Chip |

|---|---|---|

| Connection Method | Gold or aluminum wire bonds connecting die to substrate | Direct solder bumps attaching die face-down to substrate |

| Signal Performance | Higher inductance; limited high-frequency use | Lower inductance; better for RF and high-speed signals |

| Packaging Density | Limited by wire bond pitch and loop height | Higher density; supports fine pitch and smaller footptint |

| Thermal Management | Less efficient heat dissipation | Superior thermal conductivity through direct substrate contact |

| Cost | Lower upfront cost; mature process technology | Higher manufacturing cost; complex process |

| Reliability | Susceptible to wire bond lift and mechanical failure | Reduced mechanical stress; improved reliability |

| Application | Consumer electronics, automotive, standard ICs | High-performance CPUs, RF modules, advanced ICs |

Introduction to Wirebond and Flip Chip Technologies

Wirebond technology connects semiconductor chips to their packages using fine metal wires, typically gold or copper, offering reliable and cost-effective interconnections. Flip chip technology involves directly attaching the chip's active surface to the substrate using solder bumps, enabling higher interconnect density and improved electrical performance. Your choice between Wirebond and Flip chip will depend on factors such as device complexity, thermal management, and signal integrity requirements.

Key Differences Between Wirebond and Flip Chip

Wirebond uses fine metal wires to connect the semiconductor die to the package, offering lower cost and simpler manufacturing, while flip chip directly mounts the die face-down on the substrate using solder bumps, enabling higher performance and better electrical characteristics. Wirebond excels in applications requiring cost-efficiency and ease of repair, whereas flip chip supports higher input/output densities, improved thermal management, and shorter signal paths. The key differences include assembly complexity, electrical performance, thermal conductivity, and scalability for advanced packaging solutions.

Manufacturing Processes: Wirebond vs Flip Chip

Wirebond manufacturing involves attaching fine metal wires between the semiconductor die and the package substrate, using thermosonic or ultrasonic bonding techniques that offer flexibility and lower tooling costs. Flip chip manufacturing aligns the die face-down with solder bumps directly connecting to the substrate, enabling shorter electrical paths and superior high-frequency performance but requiring precise bump formation and underfill processes. Wirebond processes typically suit lower-density interconnects, while flip chip supports greater I/O density and advanced packaging solutions like system-in-package (SiP).

Performance Comparison: Signal Integrity and Speed

Wirebond technology typically exhibits higher parasitic inductance and capacitance, which can degrade signal integrity and limit high-frequency performance compared to flip chip. Flip chip offers lower interconnect length and resistance, resulting in improved signal integrity and faster signal transmission suitable for high-speed applications. The reduced parasitics in flip chip designs enable superior performance in advanced microelectronic packages requiring minimal signal distortion and high data rates.

Cost Analysis: Wirebond vs Flip Chip Packaging

Wirebond packaging generally offers lower upfront costs due to simpler manufacturing processes and established production lines, making it cost-effective for low to mid-volume applications. Flip chip packaging, while involving higher initial investment in advanced equipment and materials such as solder bumps and underfill, provides superior electrical performance and allows for higher input/output density, which can reduce overall system costs in high-performance or high-volume products. Evaluating total cost of ownership should consider not only package price but also factors like thermal management, assembly complexity, and reliability requirements.

Reliability and Durability Factors

Wirebond technology offers proven reliability with strong mechanical stability, making it suitable for applications requiring durability under thermal cycling and mechanical stress. Flip chip provides superior electrical performance and shorter interconnect paths but demands meticulous underfill processes to enhance durability and prevent solder joint fatigue. Your choice between wirebond and flip chip should consider operational environments and reliability requirements to ensure optimal long-term performance.

Applications and Use Cases

Wirebond technology remains widely used in applications requiring cost-effective, reliable connections, such as consumer electronics, automotive sensors, and power devices. Flip chip excels in high-performance computing, advanced mobile devices, and RF modules where superior electrical performance and miniaturization are crucial. Your choice depends on balancing manufacturing complexity, thermal management, and signal integrity needs specific to the application.

Thermal Management Considerations

Wirebond packages typically exhibit higher thermal resistance due to longer electrical paths and increased thermal impedance, which can hinder heat dissipation in high-power applications. Flip chip technology offers superior thermal management with direct die attachment to the substrate, enabling more efficient heat spread and reduced hotspot formation. Your choice between wirebond and flip chip should consider the thermal conductivity of the TIM materials and the overall heat dissipation requirements of the device.

Future Trends in Semiconductor Packaging

Wirebond and flip chip technologies are evolving with advances in semiconductor packaging driven by demand for higher performance and miniaturization. Fan-out wafer-level packaging (FOWLP) and 3D integration are emerging trends that combine the scalability of wirebond with the superior electrical performance of flip chip, enabling improved power efficiency and signal integrity. As you evaluate future-proof solutions, flip chip's ability to support finer interconnect pitches and heterogeneous integration makes it a preferred choice in cutting-edge applications like AI and 5G.

Choosing Between Wirebond and Flip Chip

Choosing between wirebond and flip chip depends on your device's performance, size, and cost requirements. Wirebond offers a cost-effective solution with simpler manufacturing, ideal for less complex, lower-frequency applications. Flip chip provides superior electrical performance, higher interconnect density, and better thermal management, making it suitable for high-performance, miniaturized devices.

Wirebond vs Flip chip Infographic

libmatt.com

libmatt.com