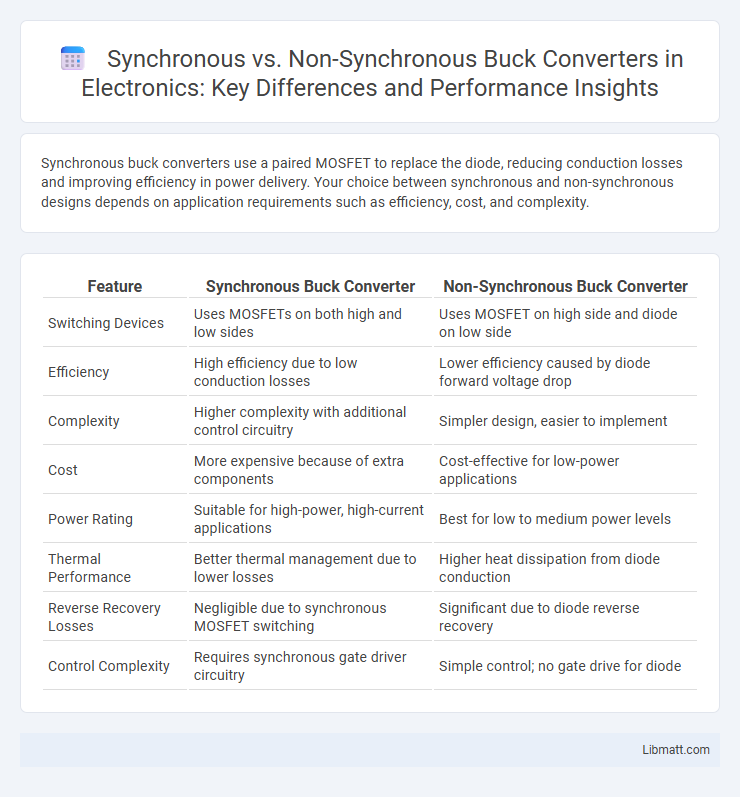

Synchronous buck converters use a paired MOSFET to replace the diode, reducing conduction losses and improving efficiency in power delivery. Your choice between synchronous and non-synchronous designs depends on application requirements such as efficiency, cost, and complexity.

Table of Comparison

| Feature | Synchronous Buck Converter | Non-Synchronous Buck Converter |

|---|---|---|

| Switching Devices | Uses MOSFETs on both high and low sides | Uses MOSFET on high side and diode on low side |

| Efficiency | High efficiency due to low conduction losses | Lower efficiency caused by diode forward voltage drop |

| Complexity | Higher complexity with additional control circuitry | Simpler design, easier to implement |

| Cost | More expensive because of extra components | Cost-effective for low-power applications |

| Power Rating | Suitable for high-power, high-current applications | Best for low to medium power levels |

| Thermal Performance | Better thermal management due to lower losses | Higher heat dissipation from diode conduction |

| Reverse Recovery Losses | Negligible due to synchronous MOSFET switching | Significant due to diode reverse recovery |

| Control Complexity | Requires synchronous gate driver circuitry | Simple control; no gate drive for diode |

Introduction to Buck Converters

Buck converters are DC-DC power regulators designed to step down voltage efficiently while maintaining high current output. Synchronous buck converters integrate MOSFET switches for reduced conduction losses and improved efficiency compared to non-synchronous versions that use diodes for the freewheeling path. Key performance metrics include voltage conversion ratio, switching frequency, and power loss, which impact thermal management and overall system reliability.

Overview of Synchronous vs Non-synchronous Designs

Synchronous buck converters use MOSFETs for both the high-side and low-side switches, significantly improving efficiency by reducing conduction losses compared to non-synchronous designs, which rely on a diode as the low-side switch. Non-synchronous converters are simpler and less costly but suffer from higher power dissipation and lower efficiency due to diode forward voltage drops. Synchronous designs are preferred in applications requiring high efficiency and thermal management, such as in power supplies for CPUs and GPUs.

Core Operating Principles

Synchronous buck converters use MOSFETs as both high-side and low-side switches, improving efficiency by reducing conduction losses compared to the diode used in non-synchronous versions. Non-synchronous buck converters rely on a diode for the low-side switch, which results in higher power dissipation during conduction due to the diode's forward voltage drop. The core operating principle of both involves regulating output voltage by rapidly switching the high-side device on and off, but synchronous converters enable better control and lower losses through actively controlled synchronous MOSFETs.

Key Components and Circuitry

Synchronous buck converters utilize MOSFETs for both the high-side and low-side switches, improving efficiency by reducing conduction losses compared to the diode used in non-synchronous buck converters. Key components in synchronous designs include a pair of complementary MOSFETs controlled by a PWM signal and a controller IC to manage switch timing, while non-synchronous designs primarily rely on a single MOSFET and a diode to regulate voltage conversion. Your choice of converter impacts circuit complexity, efficiency, and thermal performance due to the differences in components and switching mechanics.

Efficiency and Power Loss Comparison

Synchronous buck converters use MOSFETs for both the high-side and low-side switches, significantly reducing conduction losses and improving efficiency compared to non-synchronous converters that rely on diodes for the low-side switch, which introduces higher power loss due to diode forward voltage drop. Your design benefits from synchronous converters' enhanced efficiency, especially at lower output voltages and higher load currents, where reduced switching and conduction losses translate into better thermal performance and longer battery life. Efficiency gains can reach 5-10% or more, making synchronous buck converters the preferred choice for power-sensitive applications.

Performance at Light Load and Heavy Load

Synchronous buck converters offer higher efficiency at heavy loads by replacing the diode with a controlled MOSFET, reducing conduction losses and heat generation. Non-synchronous buck converters tend to perform better at light loads due to their simpler design and lower gate charge losses, which conserves energy when demand is minimal. Your choice between these converters should consider the expected load range to optimize power efficiency and thermal performance.

Cost and Complexity Analysis

Synchronous buck converters typically incur higher costs and design complexity due to the integration of MOSFETs in place of diodes, which require precise gate drive circuits and thermal management. Non-synchronous buck converters offer simpler designs and lower component costs by using diodes but sacrifice efficiency, especially at low output voltages and high currents. Evaluating cost versus performance, synchronous converters are favored in high-efficiency applications where power loss reduction justifies the increased complexity and expense.

Thermal Management Considerations

Synchronous buck converters typically offer higher efficiency than non-synchronous designs, significantly reducing heat generation and easing thermal management challenges. Non-synchronous converters rely on a diode which produces higher losses and more heat, requiring larger heat sinks or advanced cooling techniques to maintain optimal operation. Your choice between these converters directly impacts the cooling requirements and overall reliability of your power system.

Application Suitability and Use Cases

Synchronous buck converters offer higher efficiency and better thermal performance, making them ideal for battery-powered devices, laptops, and high-performance CPUs where energy savings are critical. Non-synchronous buck converters, with simpler design and lower cost, are well-suited for applications demanding lower power and less stringent efficiency, such as LED drivers and basic power supplies. Your choice depends on prioritizing efficiency and cost for applications ranging from mobile electronics to industrial equipment.

Selection Guidelines for Designers

In choosing between synchronous and non-synchronous buck converters, designers should consider efficiency, cost, and complexity; synchronous converters offer higher efficiency by replacing the diode with a MOSFET, reducing conduction losses especially at low voltages. Non-synchronous converters are simpler and more cost-effective, making them suitable for applications with moderate efficiency requirements or where design simplicity is critical. Your decision should align with system power demands, thermal management capabilities, and budget constraints to optimize performance and reliability.

Synchronous vs Non-synchronous buck converter Infographic

libmatt.com

libmatt.com