PTH assembly involves inserting components through pre-drilled holes on the PCB for strong mechanical bonds, ideal for connectors and heavy parts. SMT assembly places components directly onto the surface of the PCB, enabling higher component density and faster production, which suits most modern electronics manufacturing.

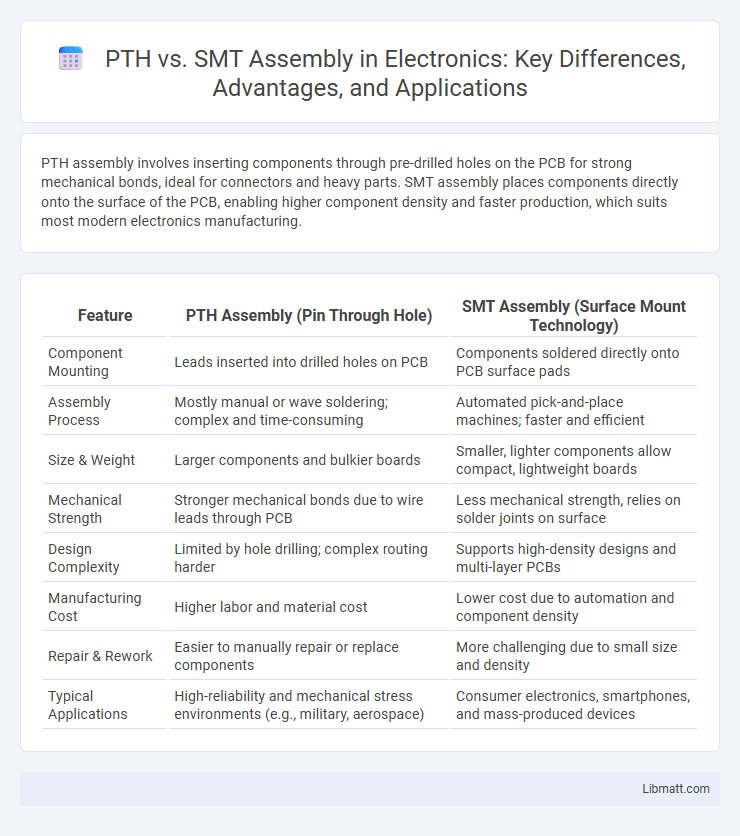

Table of Comparison

| Feature | PTH Assembly (Pin Through Hole) | SMT Assembly (Surface Mount Technology) |

|---|---|---|

| Component Mounting | Leads inserted into drilled holes on PCB | Components soldered directly onto PCB surface pads |

| Assembly Process | Mostly manual or wave soldering; complex and time-consuming | Automated pick-and-place machines; faster and efficient |

| Size & Weight | Larger components and bulkier boards | Smaller, lighter components allow compact, lightweight boards |

| Mechanical Strength | Stronger mechanical bonds due to wire leads through PCB | Less mechanical strength, relies on solder joints on surface |

| Design Complexity | Limited by hole drilling; complex routing harder | Supports high-density designs and multi-layer PCBs |

| Manufacturing Cost | Higher labor and material cost | Lower cost due to automation and component density |

| Repair & Rework | Easier to manually repair or replace components | More challenging due to small size and density |

| Typical Applications | High-reliability and mechanical stress environments (e.g., military, aerospace) | Consumer electronics, smartphones, and mass-produced devices |

Introduction to PTH and SMT Assembly

PTH (Plated Through-Hole) assembly involves inserting component leads through pre-drilled holes on a printed circuit board (PCB) and soldering them on the opposite side, providing strong mechanical bonds ideal for heavy or high-stress components. SMT (Surface Mount Technology) assembly places components directly onto the surface of the PCB using solder paste and reflow soldering, enabling higher component density and faster production speeds. Both technologies are fundamental in electronics manufacturing, with PTH favored for durability and SMT preferred for miniaturization and automation efficiency.

Definitions: What are PTH and SMT?

PTH (Plated Through-Hole) assembly involves inserting electronic components with leads through holes on a printed circuit board (PCB) and soldering them on the opposite side, providing strong mechanical bonds for heavy components. SMT (Surface Mount Technology) assembly places components directly onto the surface of the PCB pads without holes, enabling higher component density and faster production. Your choice between PTH and SMT depends on factors like component type, board design, and manufacturing volume.

Key Differences Between PTH and SMT Assembly

PTH (Plated Through-Hole) assembly involves inserting component leads into drilled holes on a PCB, providing strong mechanical bonds ideal for heavy or high-stress components. SMT (Surface Mount Technology) assembly mounts components directly onto the surface of the PCB, allowing for higher component density and faster automated production processes. PTH is preferred for durability and mechanical strength, while SMT excels in miniaturization and mass manufacturing efficiency.

Advantages of PTH Assembly

PTH (Pin Through Hole) Assembly offers superior mechanical strength due to through-hole component leads soldered on both sides of the PCB, enhancing durability under stress and vibration. This method provides reliable electrical connections for components subjected to higher power or mechanical loads, making it ideal for heavy-duty electronics and industrial applications. The robust nature of PTH assembly simplifies repairs and replacements, contributing to longer-lasting devices and easier maintenance.

Advantages of SMT Assembly

SMT Assembly offers significant advantages over PTH, including faster production speeds and increased component density, which allows for more complex and compact circuit designs. Your manufacturing process benefits from reduced labor costs and improved reliability due to less manual soldering and better electrical performance. Enhanced automation capabilities in SMT Assembly also lead to consistent quality and scalability for high-volume production.

Common Applications of PTH vs SMT

PTH (Plated Through-Hole) assembly is commonly used in applications requiring strong mechanical bonds and high reliability, such as connectors, power supplies, and heavy components in industrial and automotive electronics. SMT (Surface Mount Technology) assembly dominates in consumer electronics, telecommunications, and compact devices due to its efficiency in high-density circuit boards and automated manufacturing processes. Both technologies serve distinct roles based on component size, mechanical strength requirements, and production volume.

Assembly Process Comparison

PTH (Plated Through-Hole) assembly involves inserting component leads into drilled holes on the PCB, followed by soldering, offering strong mechanical bonds ideal for heavy or high-stress components. SMT (Surface Mount Technology) assembly places components directly onto solder paste-applied pads on the PCB surface, enabling higher component density and faster production speeds with automated pick-and-place machines. Your choice between PTH and SMT assembly depends on factors like component type, mechanical strength requirements, and manufacturing volume.

Cost Considerations for PTH and SMT

PTH (Plated Through-Hole) assembly typically incurs higher costs due to increased labor, longer production times, and the need for drilling on PCBs, which adds material and manufacturing expenses. SMT (Surface Mount Technology) assembly offers lower costs by enabling automated, high-speed placement and soldering of components directly onto the PCB surface, reducing labor and material usage. For high-volume manufacturing, SMT provides significant cost advantages with better efficiency and reduced overall production expenses compared to PTH.

Design Flexibility and Component Selection

PTH (Plated Through-Hole) assembly offers robust mechanical strength and supports larger, heavier components, providing enhanced design flexibility in environments requiring durability and high power handling. SMT (Surface Mount Technology) assembly enables higher component density, miniaturization, and automated precision, allowing designers to select smaller, more diverse components for compact and complex circuit layouts. Choosing between PTH and SMT affects component selection significantly, with PTH favoring legacy or high-reliability parts and SMT supporting advanced, high-speed, and space-efficient components.

Choosing the Right Assembly Method

Selecting between PTH (Plated Through-Hole) and SMT (Surface Mount Technology) assembly hinges on factors such as component size, board complexity, and production volume. SMT assembly is ideal for high-density designs and mass production due to its smaller component footprint and faster processing time. PTH assembly is preferred for components requiring robust mechanical support or higher power dissipation, often used in connectors and heavy-duty circuit boards.

PTH vs SMT Assembly Infographic

libmatt.com

libmatt.com