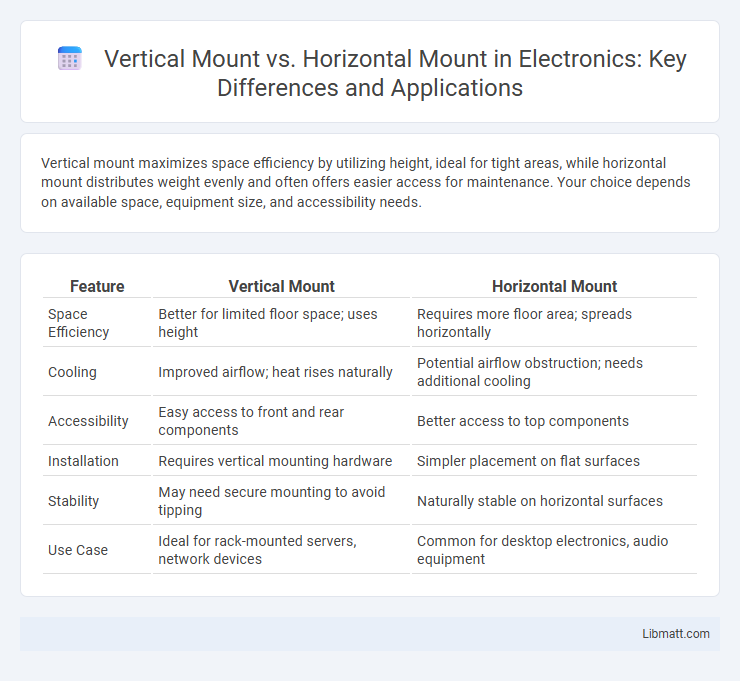

Vertical mount maximizes space efficiency by utilizing height, ideal for tight areas, while horizontal mount distributes weight evenly and often offers easier access for maintenance. Your choice depends on available space, equipment size, and accessibility needs.

Table of Comparison

| Feature | Vertical Mount | Horizontal Mount |

|---|---|---|

| Space Efficiency | Better for limited floor space; uses height | Requires more floor area; spreads horizontally |

| Cooling | Improved airflow; heat rises naturally | Potential airflow obstruction; needs additional cooling |

| Accessibility | Easy access to front and rear components | Better access to top components |

| Installation | Requires vertical mounting hardware | Simpler placement on flat surfaces |

| Stability | May need secure mounting to avoid tipping | Naturally stable on horizontal surfaces |

| Use Case | Ideal for rack-mounted servers, network devices | Common for desktop electronics, audio equipment |

Understanding Vertical Mount and Horizontal Mount

Vertical mount systems position components upright, optimizing space and improving airflow in tight areas, commonly used in server racks and industrial equipment. Horizontal mount configurations lay components flat, offering easier access and stability, preferred in desktop setups and certain machinery. Selecting between vertical and horizontal mounts depends on equipment design, space constraints, and cooling requirements to maximize performance and efficiency.

Key Differences Between Vertical and Horizontal Mount

Vertical mount installations offer a compact footprint and are ideal for saving floor space, while horizontal mounts provide greater stability and easier access for maintenance. Vertical mounts typically support LOAD capacities aligned with height restrictions, whereas horizontal mounts distribute weight more evenly across a broader base. Your choice depends on space constraints and load management requirements specific to your project.

Advantages of Vertical Mount

Vertical mount offers better space utilization in compact environments, making it ideal for small rooms or tight installations. It enhances airflow and cooling efficiency since heat rises naturally, reducing overheating risks for electronic devices. This mounting style also provides easier access for maintenance and cable management in vertical orientations.

Benefits of Horizontal Mount

Horizontal mount systems offer enhanced stability and weight distribution, making them ideal for heavy or bulky items. They facilitate easier access and maintenance, reducing downtime in industrial or mechanical applications. This mounting style also improves airflow and cooling efficiency, particularly for electronic components, ensuring optimal performance and longevity.

Application Scenarios for Vertical Mount

Vertical mount configurations are ideal for applications requiring a reduced footprint or enhanced airflow, often found in server racks, industrial machinery, and compact electronics. Your equipment benefits from improved heat dissipation and space efficiency, especially in environments with limited horizontal space. This mounting style supports vertical stacking and alignment, making it crucial for scalable, high-density setups.

Ideal Use Cases for Horizontal Mount

Horizontal mounts are ideal for applications requiring easy access and maintenance, such as in industrial control panels or equipment with frequent adjustments. They provide stable support for components like circuit breakers, relays, or HVAC controls where space allows lateral installation. You benefit from improved visibility and organized wiring pathways, optimizing operational efficiency in environments with ample horizontal clearance.

Performance Comparison: Vertical vs Horizontal

Vertical mount installations typically offer superior cooling performance due to improved airflow dynamics and natural heat dissipation, which enhances the efficiency of components in your system. Horizontal mounts may experience constrained airflow, leading to higher operating temperatures that can impact longevity and overall performance. Choosing a vertical mount can optimize thermal management, resulting in better sustained performance and reliability.

Space and Installation Considerations

Vertical mount systems maximize floor space by utilizing wall height, ideal for rooms with limited floor area but sufficient wall clearance. Horizontal mounts require more wall width but offer easier installation access and maintenance, making them suitable for wide, open spaces. Your choice depends on available space dimensions and ease of installation preference to optimize functionality and accessibility.

Cost Implications: Vertical vs Horizontal Mount

Vertical mount systems often involve higher initial installation costs due to specialized equipment and structural support requirements, whereas horizontal mounts generally offer lower expenses with simpler installation procedures. Maintenance costs for vertical mounts can also be elevated because of accessibility challenges, while horizontal mounts facilitate easier servicing and potential cost savings. Long-term cost implications favor horizontal mounts in scenarios where ease of access reduces labor and downtime expenses.

Choosing the Right Mount for Your Needs

Choosing the right mount depends on space availability and intended use, with vertical mounts saving floor area and providing easier access in tight spaces, while horizontal mounts offer enhanced stability for heavier equipment. Assessing environment constraints and device orientation is critical to ensure optimal performance and safety. Prioritize load capacity, ventilation, and maintenance accessibility to match your specific application requirements.

Vertical mount vs Horizontal mount Infographic

libmatt.com

libmatt.com