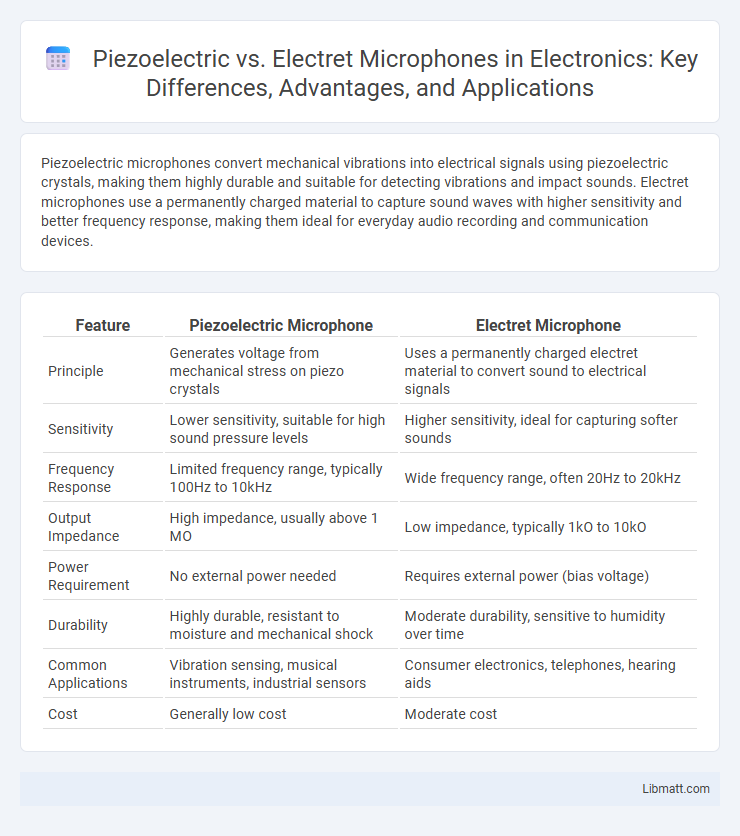

Piezoelectric microphones convert mechanical vibrations into electrical signals using piezoelectric crystals, making them highly durable and suitable for detecting vibrations and impact sounds. Electret microphones use a permanently charged material to capture sound waves with higher sensitivity and better frequency response, making them ideal for everyday audio recording and communication devices.

Table of Comparison

| Feature | Piezoelectric Microphone | Electret Microphone |

|---|---|---|

| Principle | Generates voltage from mechanical stress on piezo crystals | Uses a permanently charged electret material to convert sound to electrical signals |

| Sensitivity | Lower sensitivity, suitable for high sound pressure levels | Higher sensitivity, ideal for capturing softer sounds |

| Frequency Response | Limited frequency range, typically 100Hz to 10kHz | Wide frequency range, often 20Hz to 20kHz |

| Output Impedance | High impedance, usually above 1 MO | Low impedance, typically 1kO to 10kO |

| Power Requirement | No external power needed | Requires external power (bias voltage) |

| Durability | Highly durable, resistant to moisture and mechanical shock | Moderate durability, sensitive to humidity over time |

| Common Applications | Vibration sensing, musical instruments, industrial sensors | Consumer electronics, telephones, hearing aids |

| Cost | Generally low cost | Moderate cost |

Introduction to Microphone Technologies

Piezoelectric microphones use piezoelectric materials that generate an electrical signal when subjected to mechanical stress, making them highly durable and resistant to moisture, ideal for industrial and outdoor applications. Electret microphones incorporate a permanently charged dielectric material, offering high sensitivity and low noise performance, commonly used in consumer electronics like smartphones and hearing aids. Both technologies transform acoustic energy into electrical signals, but vary significantly in sensitivity, frequency response, and typical usage scenarios.

What is a Piezoelectric Microphone?

A piezoelectric microphone converts mechanical vibrations or sound waves into electrical signals using the piezoelectric effect, where certain materials generate voltage when subjected to pressure changes. These microphones typically consist of piezoelectric crystals or ceramics that deform under sound-induced mechanical stress, producing measurable electrical output. Piezoelectric microphones are known for their durability, low cost, and ability to operate without an external power source, making them suitable for applications like contact microphones and rugged environments.

What is an Electret Microphone?

An electret microphone is a type of condenser microphone that uses a permanently charged material called an electret to eliminate the need for external power to maintain the electric field. This design offers high sensitivity and low noise, making electret microphones ideal for applications such as smartphones, hearing aids, and portable audio devices. Compared to piezoelectric microphones, electret microphones provide better frequency response and consistent sound quality in compact, cost-effective packages.

Core Working Principles Compared

Piezoelectric microphones generate electrical signals by converting mechanical vibrations into voltage through the deformation of piezoelectric materials, making them highly durable and suitable for harsh environments. Electret microphones rely on a permanently charged dielectric material that modulates the capacitance between a diaphragm and backplate, providing stable and sensitive sound capture with minimal power consumption. Understanding these core working principles helps you select the right microphone for applications like industrial sensing or high-fidelity audio recording.

Sensitivity and Frequency Response

Piezoelectric microphones typically offer moderate sensitivity, making them suitable for detecting vibrations but less effective for capturing subtle acoustic details compared to electret microphones. Electret microphones provide higher sensitivity and a wider frequency response range, generally from 20 Hz to 20 kHz, making them ideal for high-fidelity audio recording. The frequency response of piezoelectric microphones is often limited and less flat, resulting in less accurate sound reproduction across the audible spectrum.

Durability and Environmental Resistance

Piezoelectric microphones demonstrate superior durability due to their solid-state construction, making them highly resistant to mechanical shock and extreme temperature variations. Electret microphones, while sensitive and compact, are more vulnerable to humidity and dust, which can degrade their internal electret material over time. Piezoelectric units are preferred in harsh environmental conditions where long-term stability and minimal maintenance are critical.

Power Requirements and Usage

Piezoelectric microphones operate without external power due to their ability to generate voltage from mechanical stress, making them ideal for low-power or battery-free applications. Electret microphones require a power source, typically a small bias voltage, to maintain the permanent electric charge in their dielectric material for consistent performance. Power consumption in electret microphones is minimal but necessary for amplification and signal stability in devices like smartphones and hearing aids.

Applications in Audio and Industry

Piezoelectric microphones are widely used in industrial applications due to their durability and ability to detect vibrations and ultrasonic sounds, making them ideal for machinery monitoring and harsh environments. Electret microphones excel in audio devices like smartphones, hearing aids, and voice recorders because of their high sensitivity and low noise levels. Your choice between these microphones should depend on the specific audio quality requirements and environmental conditions of your application.

Pros and Cons: Piezoelectric vs Electret

Piezoelectric microphones offer high sensitivity to vibrations and durability in harsh environments but often suffer from limited frequency response and higher noise levels. Electret microphones provide excellent sound quality, low power consumption, and consistent performance but can be more susceptible to damage from moisture and typically require a bias voltage for operation. Selecting between piezoelectric and electret microphones depends on application-specific needs such as environmental conditions, audio fidelity, and power availability.

Conclusion: Choosing the Right Microphone

Piezoelectric microphones excel in durability and high-frequency response, making them ideal for musical instrument pickups and industrial applications, while electret microphones offer superior sensitivity and low noise levels, suitable for voice recording and communication devices. Your choice depends on the specific requirements of sound quality, environmental conditions, and power availability. Opt for piezoelectric if you need ruggedness and durability; select electret for clear, consistent audio in everyday recording scenarios.

Piezoelectric vs Electret microphone Infographic

libmatt.com

libmatt.com