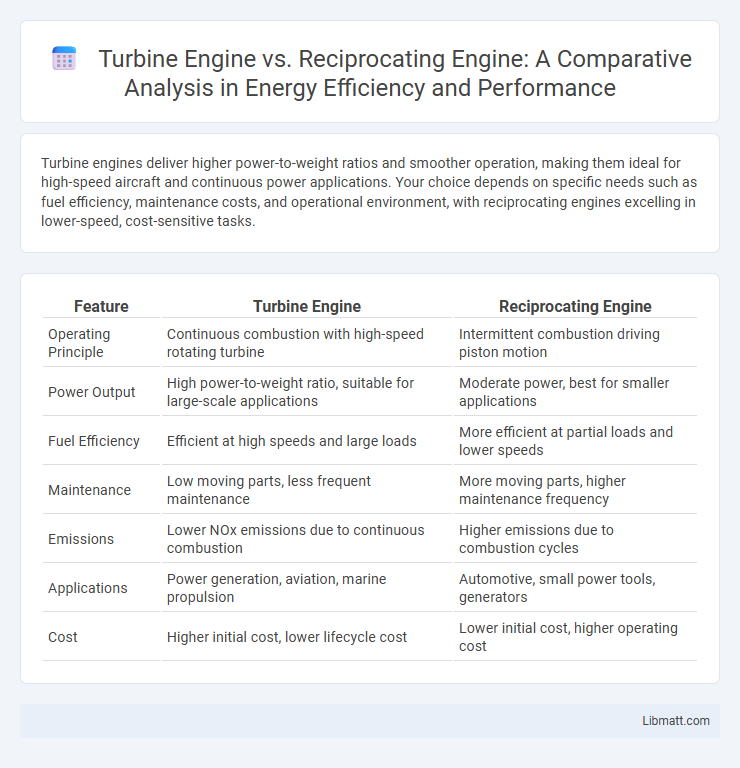

Turbine engines deliver higher power-to-weight ratios and smoother operation, making them ideal for high-speed aircraft and continuous power applications. Your choice depends on specific needs such as fuel efficiency, maintenance costs, and operational environment, with reciprocating engines excelling in lower-speed, cost-sensitive tasks.

Table of Comparison

| Feature | Turbine Engine | Reciprocating Engine |

|---|---|---|

| Operating Principle | Continuous combustion with high-speed rotating turbine | Intermittent combustion driving piston motion |

| Power Output | High power-to-weight ratio, suitable for large-scale applications | Moderate power, best for smaller applications |

| Fuel Efficiency | Efficient at high speeds and large loads | More efficient at partial loads and lower speeds |

| Maintenance | Low moving parts, less frequent maintenance | More moving parts, higher maintenance frequency |

| Emissions | Lower NOx emissions due to continuous combustion | Higher emissions due to combustion cycles |

| Applications | Power generation, aviation, marine propulsion | Automotive, small power tools, generators |

| Cost | Higher initial cost, lower lifecycle cost | Lower initial cost, higher operating cost |

Introduction to Turbine and Reciprocating Engines

Turbine engines convert energy from high-speed rotating components powered by combustion gases, offering continuous power output and efficiency at high altitudes. Reciprocating engines use pistons moving back and forth within cylinders to generate power, excelling in lower-speed applications with simpler mechanical designs. Your choice between turbine and reciprocating engines depends on performance needs, fuel efficiency, and operational environment.

Fundamental Differences Between Engine Types

Turbine engines operate on continuous combustion with high-speed rotating components, delivering greater power-to-weight ratios and efficiency at high altitudes and speeds. Reciprocating engines rely on intermittent combustion with pistons moving back and forth, making them ideal for lower-speed, lower-power applications with simpler maintenance requirements. The fundamental differences lie in their thermodynamic cycles, mechanical design, and performance characteristics tailored to distinct aerospace and automotive uses.

How Turbine Engines Work

Turbine engines operate by drawing air into a compressor, where it is pressurized before entering the combustion chamber, where fuel is ignited to produce high-velocity exhaust gases. These gases pass through turbine blades, causing them to spin and generate mechanical power for propulsion or electricity. Your understanding of turbine engine efficiency highlights their continuous combustion process, which contrasts with the intermittent explosions in reciprocating engines.

How Reciprocating Engines Operate

Reciprocating engines operate by converting the linear motion of pistons within cylinders into rotational motion through a crankshaft, using the combustion of fuel-air mixture to generate power. Each piston undergoes intake, compression, power, and exhaust strokes, providing efficient power output in small and medium-sized aircraft. Your understanding of this process highlights why reciprocating engines are favored for their simplicity and reliability in general aviation applications.

Performance and Efficiency Comparison

Turbine engines deliver higher power-to-weight ratios and operate efficiently at high speeds and altitudes, making them ideal for commercial jets and military aircraft. Reciprocating engines excel in fuel efficiency and reliability at lower speeds and altitudes, commonly powering smaller aircraft and general aviation. Your choice depends on performance requirements, with turbines favoring speed and altitude, while reciprocating engines optimize fuel consumption and maintenance.

Maintenance and Reliability Considerations

Turbine engines generally require less frequent maintenance compared to reciprocating engines due to fewer moving parts and smoother operation, leading to higher reliability in continuous-use scenarios. Reciprocating engines often demand more frequent inspections and component replacements because of mechanical complexity and increased wear from piston movement. Maintenance costs for turbine engines can be higher per event, but overall operational downtime is reduced, making them preferable in commercial aviation and high-performance applications.

Cost Factors: Initial and Operating Expenses

Turbine engines typically have higher initial costs due to advanced materials and complex manufacturing processes, while reciprocating engines are more affordable upfront because of simpler designs. Operating expenses for turbine engines include increased fuel consumption and maintenance costs associated with high-speed components, contrasting with the lower fuel efficiency but generally cheaper maintenance of reciprocating engines. The total cost of ownership balances initial investment against long-term operating efficiency and service intervals, which vary significantly between turbine and reciprocating engine applications.

Environmental Impact and Emissions

Turbine engines typically produce lower particulate emissions and fewer nitrogen oxides (NOx) compared to reciprocating engines, contributing to reduced air pollution and better compliance with environmental regulations. Reciprocating engines, often used in smaller aircraft, emit higher levels of carbon monoxide (CO), unburned hydrocarbons, and particulate matter due to incomplete combustion. The efficiency and cleaner combustion process of turbine engines result in lower greenhouse gas emissions relative to the fuel consumption of reciprocating engines.

Application Suitability in Aviation

Turbine engines, including jet and turboprop types, are ideal for high-speed commercial airliners and military aircraft due to their superior power-to-weight ratio and efficiency at high altitudes. Reciprocating engines excel in smaller general aviation aircraft and training planes because of their lower operating costs and simpler maintenance requirements. The choice between turbine and reciprocating engines hinges on mission profile, with turbines favored for long-range and heavy payloads, while reciprocating engines suit short-range, lower-speed flights.

Future Trends in Aircraft Engine Technology

Turbine engines are advancing towards higher efficiency and reduced emissions through innovations like geared turbofans and hybrid-electric propulsion systems, while reciprocating engines see ongoing development for light aircraft with improved fuel injection and alternative fuels to enhance performance. The integration of additive manufacturing and advanced materials is driving weight reduction and durability improvements in both engine types. Emerging trends emphasize electrification and sustainable fuels to meet stringent environmental regulations and support the aviation industry's shift towards greener technologies.

Turbine Engine vs Reciprocating Engine Infographic

libmatt.com

libmatt.com