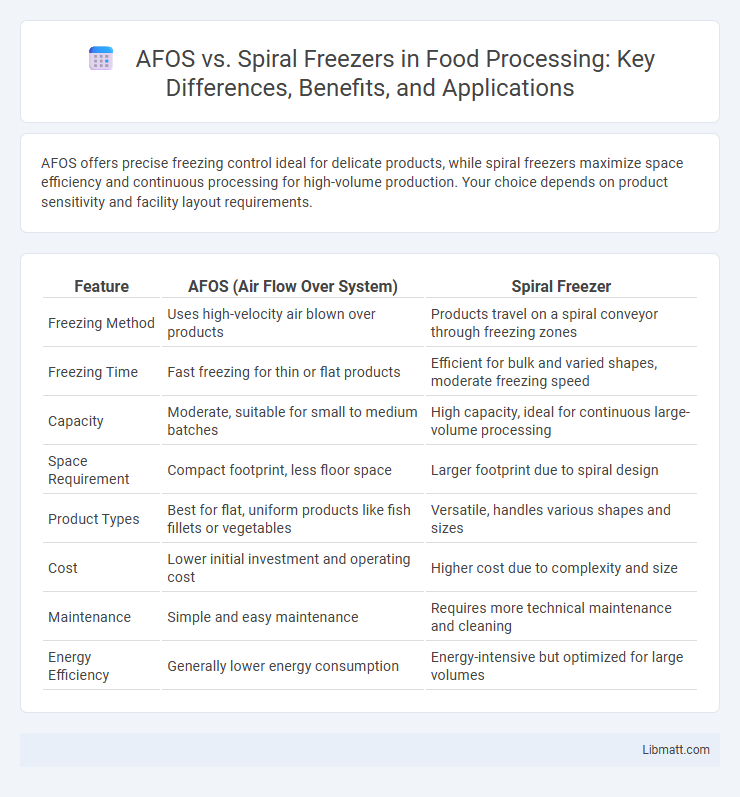

AFOS offers precise freezing control ideal for delicate products, while spiral freezers maximize space efficiency and continuous processing for high-volume production. Your choice depends on product sensitivity and facility layout requirements.

Table of Comparison

| Feature | AFOS (Air Flow Over System) | Spiral Freezer |

|---|---|---|

| Freezing Method | Uses high-velocity air blown over products | Products travel on a spiral conveyor through freezing zones |

| Freezing Time | Fast freezing for thin or flat products | Efficient for bulk and varied shapes, moderate freezing speed |

| Capacity | Moderate, suitable for small to medium batches | High capacity, ideal for continuous large-volume processing |

| Space Requirement | Compact footprint, less floor space | Larger footprint due to spiral design |

| Product Types | Best for flat, uniform products like fish fillets or vegetables | Versatile, handles various shapes and sizes |

| Cost | Lower initial investment and operating cost | Higher cost due to complexity and size |

| Maintenance | Simple and easy maintenance | Requires more technical maintenance and cleaning |

| Energy Efficiency | Generally lower energy consumption | Energy-intensive but optimized for large volumes |

Introduction to AFOS and Spiral Freezers

AFOS (Automated Food Operating Systems) and spiral freezers are critical components in modern food processing. AFOS integrates advanced automation to enhance precision and efficiency in food handling, while spiral freezers employ a continuous conveyor belt system that coils food products in a space-saving spiral for rapid, uniform freezing. Both technologies optimize production throughput and product quality in industrial freezing applications.

Overview of Freezing Technologies

AFOS (Advanced Freeze-on-Set) technology offers rapid freezing by directly immersing products in cryogenic liquids, ensuring minimal ice crystal formation and preserving texture and flavor. Spiral freezers utilize a continuous conveyor belt system that circulates food through cold air chambers, providing consistent freezing for high-volume production lines. Compared to spiral freezers, AFOS delivers faster freezing times and superior product quality, especially for delicate items, while spiral freezers excel in energy efficiency and large-scale throughput.

Key Features of AFOS Freezers

AFOS freezers utilize advanced ammonia-based refrigeration systems that offer rapid and uniform freezing, preserving food texture and nutritional value effectively. These freezers feature customizable airflow patterns and precise temperature controls to optimize freezing cycles and enhance energy efficiency. Their modular design supports scalability and easy maintenance, making AFOS freezers ideal for high-capacity industrial food processing.

Key Features of Spiral Freezers

Spiral freezers feature a continuous belt system that maximizes freezing efficiency by exposing products to cold air in a compact vertical design, saving valuable floor space. They offer advanced temperature control and adjustable belt speeds, allowing precise freezing tailored to various food products such as seafood, meat, and bakery items. The spiral freezer's energy-efficient operation and improved airflow distribution ensure consistent product quality by minimizing thawing and dehydration during the freezing process.

Performance Comparison: AFOS vs Spiral Freezer

AFOS delivers higher processing capacity and more uniform freezing compared to traditional spiral freezers, optimizing product quality and reducing energy consumption. The advanced airflow system in AFOS ensures faster heat transfer rates, enhancing freeze efficiency and minimizing dehydration loss. Spiral freezers offer compact design and continuous operation but often lag behind AFOS in temperature consistency and throughput for high-demand industrial applications.

Energy Efficiency Analysis

AFOS systems typically offer higher energy efficiency compared to spiral freezers by reducing air recirculation and optimizing heat transfer through rotating airflow technology. Spiral freezers consume more energy due to continuous belt movement and extensive refrigeration load to maintain consistent freezing throughout the spiral belt. Evaluating your specific processing needs can determine which technology minimizes energy consumption while maintaining product quality.

Space and Footprint Considerations

AFOS systems generally require less floor space due to their vertical stacking design, making them ideal for facilities with limited footprint availability. Spiral freezers, while offering high throughput, demand a larger horizontal footprint because of their extended conveyor belt loops. Your choice depends on balancing space constraints with processing capacity needs to optimize production efficiency.

Product Quality and Consistency

AFOS technology ensures superior product quality by maintaining uniform airflow and precise temperature control, resulting in consistent freezing and minimal texture degradation. Spiral freezers provide high capacity but may experience variations in product consistency due to uneven airflow distribution across the spiral path. Your choice depends on prioritizing exacting quality standards, where AFOS offers enhanced consistency for delicate or premium products.

Cost and Maintenance Factors

AFOS systems generally offer lower upfront costs compared to Spiral Freezers due to simpler construction and reduced installation complexity. Maintenance for AFOS is often less intensive, with fewer moving parts and easier access for repairs, while Spiral Freezers require regular servicing of their conveyor belts and motor components, which can increase operational expenses. You should consider the total cost of ownership, including long-term maintenance, when deciding between AFOS and Spiral Freezers for your freezing needs.

Choosing the Right Freezing Solution

Selecting the right freezing solution between AFOS and Spiral Freezers depends on product type, production capacity, and space constraints. AFOS (Air Fluidized Oven System) provides uniform freezing with excellent airflow for delicate or irregularly shaped products, while Spiral Freezers offer continuous, high-capacity freezing ideal for standardized products like seafood or baked goods. Consider processing speed, energy efficiency, and maintenance requirements to optimize freezing performance and product quality.

AFOS vs Spiral Freezer Infographic

libmatt.com

libmatt.com