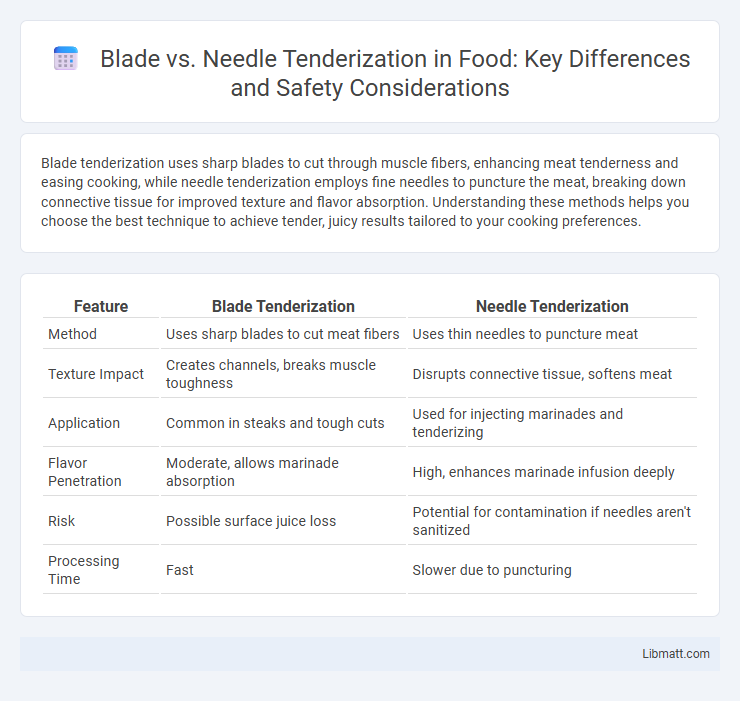

Blade tenderization uses sharp blades to cut through muscle fibers, enhancing meat tenderness and easing cooking, while needle tenderization employs fine needles to puncture the meat, breaking down connective tissue for improved texture and flavor absorption. Understanding these methods helps you choose the best technique to achieve tender, juicy results tailored to your cooking preferences.

Table of Comparison

| Feature | Blade Tenderization | Needle Tenderization |

|---|---|---|

| Method | Uses sharp blades to cut meat fibers | Uses thin needles to puncture meat |

| Texture Impact | Creates channels, breaks muscle toughness | Disrupts connective tissue, softens meat |

| Application | Common in steaks and tough cuts | Used for injecting marinades and tenderizing |

| Flavor Penetration | Moderate, allows marinade absorption | High, enhances marinade infusion deeply |

| Risk | Possible surface juice loss | Potential for contamination if needles aren't sanitized |

| Processing Time | Fast | Slower due to puncturing |

Introduction to Meat Tenderization Techniques

Meat tenderization techniques such as blade tenderization and needle tenderization improve the texture and juiciness of cuts by breaking down muscle fibers and connective tissues. Blade tenderization uses sharp blades to mechanically pierce the meat, creating small channels that enhance marinade absorption and cooking evenness. Needle tenderization employs slender needles to puncture the meat more deeply, which helps maintain structural integrity while enhancing tenderness and flavor penetration for your culinary preparation.

What Is Blade Tenderization?

Blade tenderization uses sharp blades to mechanically pierce and cut through meat fibers, breaking down connective tissues and enhancing tenderness and flavor absorption. This method contrasts with needle tenderization, which uses thin needles to puncture the meat without extensive cutting. Your choice of blade tenderization can significantly improve the texture of tougher cuts, making them more enjoyable to eat.

What Is Needle Tenderization?

Needle tenderization is a meat processing technique that uses fine needles to pierce the muscle tissue, breaking down tough fibers and improving texture and tenderness. This method allows marinades and seasonings to penetrate deeper, enhancing flavor and juiciness. If you seek a tender, flavorful cut, needle tenderization can significantly improve your meat's eating quality.

Comparing Blade and Needle Tenderization Methods

Blade tenderization involves cutting into the meat with sharp blades to break up muscle fibers, enhancing tenderness and allowing marinades to penetrate more effectively. Needle tenderization uses multiple thin needles that puncture the meat, disrupting connective tissues while preserving a more intact surface structure. Comparing both methods, blade tenderization typically produces more uniform tenderness and faster marinade absorption, whereas needle tenderization is favored for maintaining the meat's original appearance and reducing surface damage.

Impact on Meat Texture and Juiciness

Blade tenderization uses multiple small blades to cut through muscle fibers, resulting in a more consistent texture and enhanced juiciness by allowing marinades to penetrate deeper. Needle tenderization employs thin needles that pierce the meat, breaking down connective tissues to improve tenderness while preserving the meat's natural juiciness. Both methods effectively enhance tenderness, but blade tenderization tends to create a slightly moister texture due to its impact on muscle fiber structure.

Safety Concerns: Bacterial Risks and Mitigation

Blade tenderization involves slicing meat with sharp blades, which can push surface bacteria deeper into the tissue, increasing bacterial risks if the meat is not cooked thoroughly. Needle tenderization, using multiple needles to penetrate the meat, poses similar safety concerns by transferring surface pathogens internally, requiring careful handling and cooking to mitigate contamination. Your best risk management practices include sourcing meat from reputable suppliers, maintaining strict hygiene during processing, and ensuring proper cooking temperatures to neutralize bacteria introduced during tenderization.

Costs and Operational Efficiency

Blade tenderization generally incurs lower initial equipment costs compared to needle tenderization, making it a more budget-friendly choice for processing plants. Operational efficiency favors blade systems due to faster processing times and minimal maintenance requirements, which reduce labor expenses and downtime. Your decision should balance these cost differences with the specific tenderization quality needs of your production.

Industry Preferences and Trends

Blade tenderization dominates the industry due to its efficiency, cost-effectiveness, and ability to improve tenderness without compromising the meat's exterior appearance. Needle tenderization, while offering deeper penetration and enhanced marinade absorption, faces scrutiny over food safety concerns, influencing limited adoption in some sectors. Your choice between these methods should consider current industry standards, regulatory guidelines, and the desired balance between product quality and operational efficiency.

Consumer Perspectives and Labeling

Consumers often perceive blade tenderization as a more natural and less intrusive method compared to needle tenderization, influencing their purchasing decisions. Labeling regulations require clear disclosure of needle tenderization due to potential food safety concerns, alerting consumers to the mechanical injection process and associated risks. Transparent labeling increases consumer trust and allows informed choices based on preferences for meat texture and safety standards.

Conclusion: Choosing the Right Tenderization Method

Blade tenderization uses sharp blades to cut muscle fibers, enhancing tenderness quickly but risking surface contamination if not cooked properly. Needle tenderization involves inserting multiple fine needles to break down connective tissue, improving texture while maintaining juice retention and flavor. Your choice depends on the desired tenderness, cooking method, and food safety considerations, as blade tenderization suits faster cooking, while needle tenderization works better for thicker cuts requiring deeper penetration.

Blade Tenderization vs Needle Tenderization Infographic

libmatt.com

libmatt.com