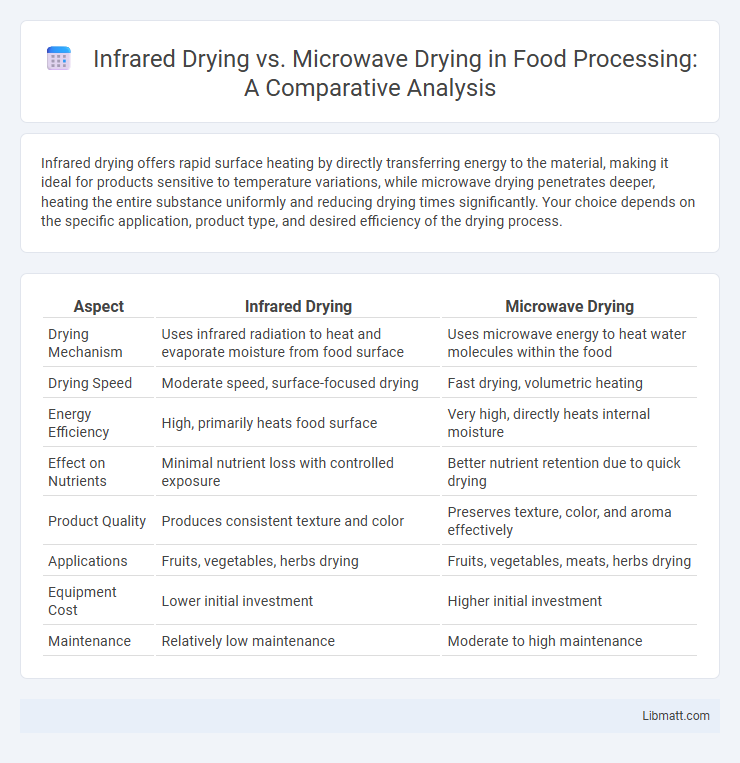

Infrared drying offers rapid surface heating by directly transferring energy to the material, making it ideal for products sensitive to temperature variations, while microwave drying penetrates deeper, heating the entire substance uniformly and reducing drying times significantly. Your choice depends on the specific application, product type, and desired efficiency of the drying process.

Table of Comparison

| Aspect | Infrared Drying | Microwave Drying |

|---|---|---|

| Drying Mechanism | Uses infrared radiation to heat and evaporate moisture from food surface | Uses microwave energy to heat water molecules within the food |

| Drying Speed | Moderate speed, surface-focused drying | Fast drying, volumetric heating |

| Energy Efficiency | High, primarily heats food surface | Very high, directly heats internal moisture |

| Effect on Nutrients | Minimal nutrient loss with controlled exposure | Better nutrient retention due to quick drying |

| Product Quality | Produces consistent texture and color | Preserves texture, color, and aroma effectively |

| Applications | Fruits, vegetables, herbs drying | Fruits, vegetables, meats, herbs drying |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Maintenance | Relatively low maintenance | Moderate to high maintenance |

Introduction to Infrared and Microwave Drying

Infrared drying uses electromagnetic radiation with wavelengths typically between 0.7 to 1.5 microns, penetrating the material's surface to generate heat efficiently, making it ideal for uniform moisture removal from food or industrial products. Microwave drying utilizes microwave radiation, usually at frequencies of 915 MHz or 2.45 GHz, causing water molecules within the material to vibrate and generate heat internally, enabling faster drying times and energy efficiency compared to conventional methods. Your choice between infrared and microwave drying depends on the desired drying speed, product characteristics, and energy consumption priorities.

Principles of Infrared Drying

Infrared drying operates by emitting infrared radiation that penetrates material surfaces, converting light energy into heat to evaporate moisture efficiently. Unlike microwave drying, which heats water molecules directly through electromagnetic waves, infrared targets the surface layer, resulting in uniform temperature distribution and reduced drying times. Your choice of infrared drying enhances energy efficiency and preserves product quality by minimizing thermal degradation.

Principles of Microwave Drying

Microwave drying utilizes electromagnetic waves in the microwave frequency range to generate heat directly within the material by exciting water molecules, leading to rapid internal moisture evaporation. This volumetric heating principle contrasts with infrared drying, which relies on surface heat transfer through radiation, causing slower moisture migration from the interior to the surface. Microwave drying achieves uniform temperature distribution and faster drying rates, reducing processing time and energy consumption in industrial applications.

Energy Efficiency Comparison

Infrared drying generally offers higher energy efficiency by directly heating the surface of materials, resulting in reduced heat loss and faster drying times compared to microwave drying, which heats materials volumetrically but may cause uneven energy distribution. Microwave drying can consume more power due to the complexity of electromagnetic energy absorption, yet it often achieves uniform moisture removal without overheating the surface. Your choice between infrared and microwave drying should consider the specific moisture content, material properties, and energy consumption rates to optimize operational efficiency.

Drying Speed and Process Time

Infrared drying offers rapid surface heating, resulting in faster initial moisture removal but may require longer overall process time for uniform drying. Microwave drying penetrates materials deeply, significantly reducing drying speed and overall process time by heating from the inside out. Your choice depends on the balance between drying speed and quality requirements specific to the application.

Effects on Product Quality

Infrared drying preserves product color and nutrient content by providing uniform and gentle heating, minimizing thermal degradation and moisture loss. Microwave drying offers rapid dehydration that retains volatile compounds and bioactive elements but may cause uneven heating, leading to hotspots and potential quality deterioration. Both methods enhance drying efficiency while impacting texture and flavor retention differently based on product type and drying parameters.

Applications in Food and Pharmaceutical Industries

Infrared drying is extensively used in the food industry for surface drying of fruits, vegetables, and herbs, offering energy efficiency and uniform heat distribution, which helps preserve flavor and nutrients. In contrast, microwave drying excels in pharmaceutical applications by enabling rapid moisture removal from heat-sensitive drugs and granules while maintaining structural integrity and bioactivity. Both methods support industrial scalability, with infrared drying favored for its low operational cost and microwave drying preferred for its precision and speed in complex formulations.

Equipment and Cost Analysis

Infrared drying equipment typically consists of infrared lamps and emitters that provide direct heat, offering high energy efficiency and lower initial investment compared to microwave drying systems. Microwave drying machines utilize magnetrons or solid-state generators to produce electromagnetic waves, resulting in faster drying times but higher equipment costs and maintenance expenses. The capital cost for industrial-scale infrared dryers generally ranges from $10,000 to $50,000, whereas microwave drying units can exceed $100,000, reflecting differences in technology complexity and operational speed.

Environmental Impact and Sustainability

Infrared drying consumes less energy and produces fewer greenhouse gas emissions compared to microwave drying, making it a more environmentally friendly option. Microwave drying often requires higher electricity input, which can increase its carbon footprint depending on the energy source. Choosing infrared drying can enhance your sustainability efforts by reducing energy consumption and minimizing environmental impact.

Choosing the Right Drying Technology

Infrared drying offers rapid surface heating suitable for thin or delicate materials, while microwave drying provides volumetric heating ideal for uniform moisture removal in dense or bulky products. Selecting the right drying technology depends on factors such as product type, moisture content, energy efficiency, and desired drying speed. Evaluating these parameters ensures optimal drying performance, cost-effectiveness, and product quality preservation.

Infrared Drying vs Microwave Drying Infographic

libmatt.com

libmatt.com