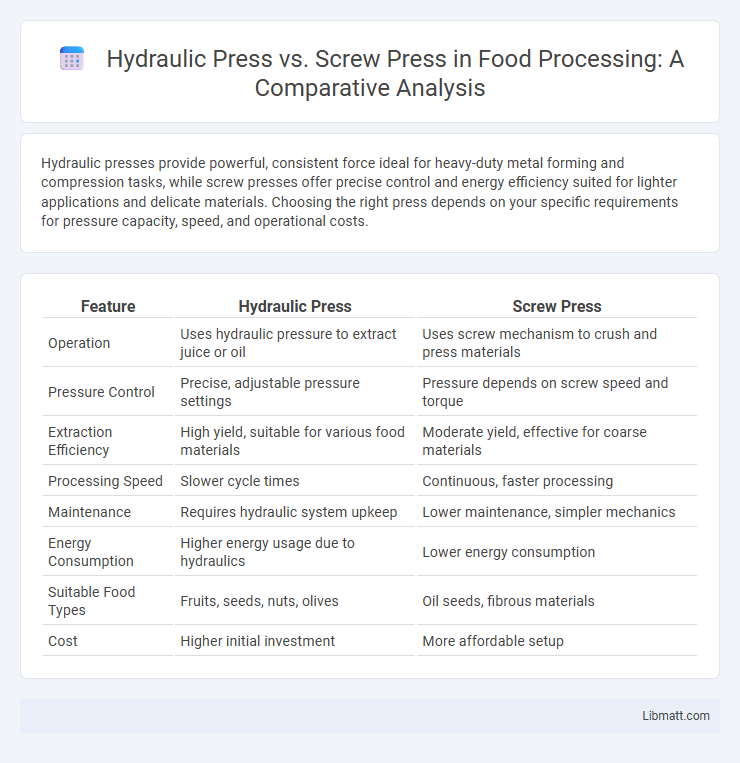

Hydraulic presses provide powerful, consistent force ideal for heavy-duty metal forming and compression tasks, while screw presses offer precise control and energy efficiency suited for lighter applications and delicate materials. Choosing the right press depends on your specific requirements for pressure capacity, speed, and operational costs.

Table of Comparison

| Feature | Hydraulic Press | Screw Press |

|---|---|---|

| Operation | Uses hydraulic pressure to extract juice or oil | Uses screw mechanism to crush and press materials |

| Pressure Control | Precise, adjustable pressure settings | Pressure depends on screw speed and torque |

| Extraction Efficiency | High yield, suitable for various food materials | Moderate yield, effective for coarse materials |

| Processing Speed | Slower cycle times | Continuous, faster processing |

| Maintenance | Requires hydraulic system upkeep | Lower maintenance, simpler mechanics |

| Energy Consumption | Higher energy usage due to hydraulics | Lower energy consumption |

| Suitable Food Types | Fruits, seeds, nuts, olives | Oil seeds, fibrous materials |

| Cost | Higher initial investment | More affordable setup |

Introduction to Hydraulic Press vs Screw Press

Hydraulic presses use fluid pressure to generate a strong, consistent force ideal for metal forming and molding applications, providing precise control over pressure and speed. Screw presses rely on mechanical energy transferred through a rotating screw to apply pressure, offering efficient energy use and simpler maintenance for tasks like forging and compacting. Both presses serve distinct industrial needs, with hydraulic presses favored for high-force, adjustable operations and screw presses valued for their robust, cost-effective performance.

Working Principle of Hydraulic Press

The working principle of a hydraulic press relies on Pascal's law, where a small force applied to a confined fluid generates a larger force through a hydraulic cylinder to compress or mold materials. This press uses hydraulic fluid to transmit pressure evenly, enabling precise and powerful pressing operations for metal forming, molding, or assembly tasks. Your choice between hydraulic and screw press depends on the need for consistent force and control, as hydraulic presses offer smooth and adjustable pressure ideal for delicate or heavy-duty applications.

Working Principle of Screw Press

The working principle of a screw press involves a rotating screw that compresses material within a cylindrical casing, generating pressure to extract liquids or shape materials. You control the pressure by adjusting the screw speed and feed rate, allowing precise handling of various substances like oilseeds or biomass. This mechanical design offers consistent, efficient extraction and is favored for continuous processing in industries such as food, agriculture, and recycling.

Key Differences Between Hydraulic and Screw Press

Hydraulic presses utilize fluid pressure to generate high force with precise control, making them ideal for applications requiring consistent pressure and versatility in stroke length. Screw presses operate via mechanical rotation of a screw, offering high force and energy efficiency but typically limited to shorter strokes and faster cycling times. The key differences lie in force generation, control precision, speed, and suitability for complex forming versus high-volume production tasks.

Advantages of Hydraulic Press

Hydraulic presses offer significant advantages such as higher force capacity, allowing for precise control over pressure and speed, which ensures consistent and accurate results in metal forming and molding applications. Their ability to maintain constant pressure throughout the stroke improves product quality, reduces material waste, and supports complex shaping processes. You benefit from greater energy efficiency and lower maintenance needs compared to screw presses, making hydraulic presses ideal for heavy-duty industrial operations.

Advantages of Screw Press

Screw presses offer significant advantages including higher energy efficiency and lower maintenance costs compared to hydraulic presses. Their design allows for continuous operation, making them ideal for processes requiring consistent pressure and speed. Your choice of a screw press can lead to improved productivity and reduced operational downtime.

Applications of Hydraulic Press

Hydraulic presses are widely used in automotive manufacturing for forming metal parts, in aerospace for composite shaping, and in industrial settings for metal stamping, forging, and molding plastic components. They offer precise control over pressure and force, making them ideal for applications requiring consistent and high-strength output. Your production process benefits from their versatility in both heavy-duty and delicate material handling tasks.

Applications of Screw Press

Screw presses are widely used in industries such as oil extraction, paper recycling, and food processing due to their efficient solid-liquid separation capabilities. Their applications include dewatering biomass, extracting oils from seeds, and compacting waste materials to reduce volume in recycling plants. You benefit from their continuous operation and consistent pressure control, making them ideal for tasks requiring precise material handling and moisture removal.

Cost Comparison: Hydraulic vs Screw Press

Hydraulic presses generally have higher upfront costs compared to screw presses due to their complex design and advanced components, but they offer greater force control and versatility, which can lead to improved product quality and reduced waste. Screw presses typically require lower initial investment and lower maintenance expenses, making them suitable for operations with budget constraints or simpler applications. Over time, the total cost of ownership for hydraulic presses may be offset by enhanced efficiency and precision, especially in heavy-duty or high-volume production environments.

Which Press is Best for Your Needs?

Hydraulic presses provide consistent pressure and are ideal for applications requiring high force and precise control, making them suitable for heavy-duty tasks like metal forming or molding. Screw presses offer efficient, high-speed operation with adjustable pressure, best for processes needing quick cycling and moderate force such as compacting or punching. Your choice depends on whether you prioritize maximum force and accuracy or speed and efficiency for your specific industrial needs.

Hydraulic Press vs Screw Press Infographic

libmatt.com

libmatt.com