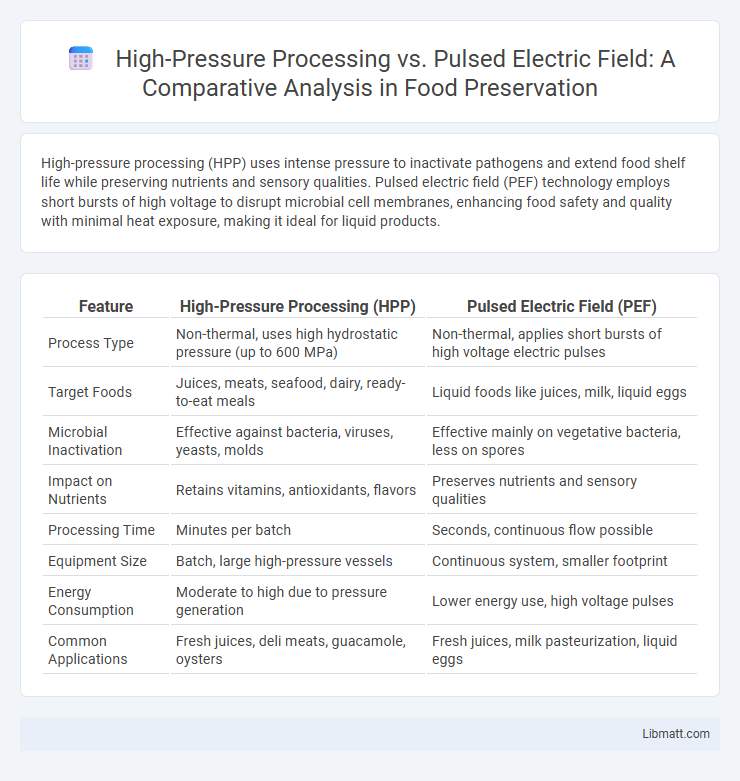

High-pressure processing (HPP) uses intense pressure to inactivate pathogens and extend food shelf life while preserving nutrients and sensory qualities. Pulsed electric field (PEF) technology employs short bursts of high voltage to disrupt microbial cell membranes, enhancing food safety and quality with minimal heat exposure, making it ideal for liquid products.

Table of Comparison

| Feature | High-Pressure Processing (HPP) | Pulsed Electric Field (PEF) |

|---|---|---|

| Process Type | Non-thermal, uses high hydrostatic pressure (up to 600 MPa) | Non-thermal, applies short bursts of high voltage electric pulses |

| Target Foods | Juices, meats, seafood, dairy, ready-to-eat meals | Liquid foods like juices, milk, liquid eggs |

| Microbial Inactivation | Effective against bacteria, viruses, yeasts, molds | Effective mainly on vegetative bacteria, less on spores |

| Impact on Nutrients | Retains vitamins, antioxidants, flavors | Preserves nutrients and sensory qualities |

| Processing Time | Minutes per batch | Seconds, continuous flow possible |

| Equipment Size | Batch, large high-pressure vessels | Continuous system, smaller footprint |

| Energy Consumption | Moderate to high due to pressure generation | Lower energy use, high voltage pulses |

| Common Applications | Fresh juices, deli meats, guacamole, oysters | Fresh juices, milk pasteurization, liquid eggs |

Introduction to High-Pressure Processing and Pulsed Electric Field

High-Pressure Processing (HPP) uses extreme pressure to inactivate microorganisms and enzymes in food, preserving freshness and nutrients without heat. Pulsed Electric Field (PEF) technology applies short bursts of high voltage to disrupt microbial cells, enhancing food safety and extending shelf life while maintaining sensory qualities. Your choice between HPP and PEF depends on the specific food matrix and desired preservation outcomes.

How High-Pressure Processing Works

High-Pressure Processing (HPP) works by applying intense pressure, up to 600 MPa, uniformly around food products, inactivating harmful bacteria, yeasts, and molds while preserving nutrients and sensory qualities. This non-thermal method disrupts microbial cell membranes and enzyme activity without significantly raising temperature, maintaining food freshness and extending shelf life. Your food undergoes minimal chemical changes, ensuring safety and quality without additives or preservatives.

The Science Behind Pulsed Electric Field

Pulsed electric field (PEF) technology uses short bursts of high voltage electric pulses to disrupt microbial cell membranes, enhancing food preservation without significant heat application. This method maintains nutritional quality and sensory attributes by inducing electroporation, which increases cell permeability and inactivates pathogens and spoilage organisms. Compared to high-pressure processing, PEF offers precise control over electrical parameters, enabling scalable, energy-efficient microbial inactivation while preserving texture and freshness in various food matrices.

Comparing Mechanisms: HPP vs PEF

High-pressure processing (HPP) uses intense pressure, typically up to 600 MPa, to inactivate microorganisms by disrupting cellular membranes and protein structures, preserving food quality without heat. Pulsed electric field (PEF) technology applies short bursts of high voltage to create pores in cell membranes (electroporation), leading to microbial inactivation while maintaining sensory and nutritional properties. Both methods effectively enhance food safety and shelf life through non-thermal preservation but differ in their mechanical versus electrical disruption mechanisms.

Food Safety and Microbial Inactivation

High-pressure processing (HPP) and pulsed electric field (PEF) technologies enhance food safety by effectively inactivating microorganisms without compromising nutritional quality. HPP disrupts microbial cell membranes via intense isostatic pressure, achieving significant reductions in pathogens such as Listeria monocytogenes and Escherichia coli. PEF inactivates microorganisms by inducing electroporation, targeting spoilage bacteria and viruses with minimal thermal effects, thereby preserving sensory attributes while ensuring product safety.

Impact on Nutritional and Sensory Quality

High-pressure processing preserves the nutritional content of fruits and vegetables by inactivating microbes with minimal heat, retaining vitamins, antioxidants, and natural flavors more effectively than thermal treatments. Pulsed electric field (PEF) technology enhances juice extraction and microbial safety while maintaining sensory attributes like color, aroma, and taste due to its non-thermal nature and short processing times. Both methods demonstrate superior retention of nutrients and sensory quality compared to conventional pasteurization, with high-pressure processing showing slightly better preservation of texture in solid foods.

Application in Food and Beverage Industries

High-pressure processing (HPP) is widely used in the food and beverage industries for pasteurizing juices, dairy products, and ready-to-eat meals by inactivating microbes while preserving flavor and nutrients. Pulsed electric field (PEF) technology offers rapid microbial inactivation in liquid foods like fruit juices and milk, enhancing shelf life and maintaining freshness without heat damage. Your choice between HPP and PEF depends on the product type and desired quality outcomes, as both methods provide innovative solutions for extending shelf life and improving food safety.

Advantages and Limitations of HPP

High-pressure processing (HPP) offers significant advantages such as retaining nutritional quality, extending shelf life without chemical preservatives, and effectively inactivating pathogens while maintaining the food's original taste and texture. Limitations include the high cost of equipment and energy consumption, challenges in processing solid foods with irregular shapes, and potential impact on the texture of certain delicate products. Your choice between HPP and pulsed electric field methods depends on balancing these benefits against the operational constraints and specific food product requirements.

Benefits and Drawbacks of PEF

Pulsed Electric Field (PEF) technology preserves food quality by inactivating microbes without significant heat, maintaining flavor, nutrients, and texture better than traditional methods. This non-thermal process offers energy efficiency and rapid treatment times compared to High-Pressure Processing (HPP), but its effectiveness is limited to liquid or semi-liquid foods, restricting its broader application. High capital costs and potential equipment complexity pose additional challenges, while HPP can treat solid and liquid foods with uniform microbial inactivation.

Future Trends and Innovations in Food Preservation

High-pressure processing (HPP) and pulsed electric field (PEF) technologies are advancing rapidly, with innovations aiming to enhance microbial inactivation while preserving nutritional quality and sensory attributes of foods. Future trends include integrating these methods with smart sensors and AI for real-time monitoring and precision control, improving energy efficiency and scalability for commercial use. Your food preservation strategies can benefit from these developments, enabling safer, fresher products with extended shelf life and reduced reliance on chemical preservatives.

high-pressure processing vs pulsed electric field Infographic

libmatt.com

libmatt.com