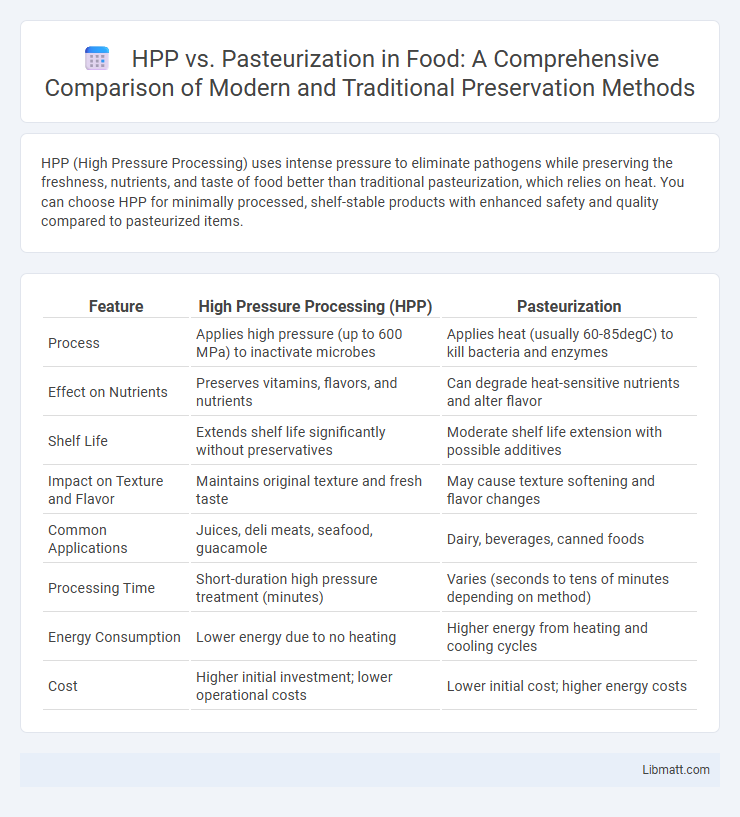

HPP (High Pressure Processing) uses intense pressure to eliminate pathogens while preserving the freshness, nutrients, and taste of food better than traditional pasteurization, which relies on heat. You can choose HPP for minimally processed, shelf-stable products with enhanced safety and quality compared to pasteurized items.

Table of Comparison

| Feature | High Pressure Processing (HPP) | Pasteurization |

|---|---|---|

| Process | Applies high pressure (up to 600 MPa) to inactivate microbes | Applies heat (usually 60-85degC) to kill bacteria and enzymes |

| Effect on Nutrients | Preserves vitamins, flavors, and nutrients | Can degrade heat-sensitive nutrients and alter flavor |

| Shelf Life | Extends shelf life significantly without preservatives | Moderate shelf life extension with possible additives |

| Impact on Texture and Flavor | Maintains original texture and fresh taste | May cause texture softening and flavor changes |

| Common Applications | Juices, deli meats, seafood, guacamole | Dairy, beverages, canned foods |

| Processing Time | Short-duration high pressure treatment (minutes) | Varies (seconds to tens of minutes depending on method) |

| Energy Consumption | Lower energy due to no heating | Higher energy from heating and cooling cycles |

| Cost | Higher initial investment; lower operational costs | Lower initial cost; higher energy costs |

Introduction to HPP and Pasteurization

High Pressure Processing (HPP) uses intense pressure to eliminate pathogens and extend shelf life while preserving food's nutrients and flavor, contrasting with traditional pasteurization that applies heat to achieve microbial safety. HPP maintains the freshness and texture of foods without thermal damage, making it ideal for sensitive products like juices and deli meats. Your choice between HPP and pasteurization depends on desired product quality, shelf life, and nutritional retention.

How HPP (High Pressure Processing) Works

High Pressure Processing (HPP) utilizes intense pressure, typically between 400 to 600 MPa, to inactivate pathogens and spoilage microorganisms in food without applying heat. This method preserves the texture, flavor, and nutritional value of your products by avoiding high temperatures used in traditional pasteurization. HPP's non-thermal mechanism disrupts microbial cell membranes while maintaining food quality and safety effectively.

Traditional Pasteurization Explained

Traditional pasteurization involves heating liquids such as milk or juice to specific temperatures (typically 72degC for 15 seconds) to kill pathogenic bacteria and extend shelf life. This thermal process can alter taste, texture, and nutrient content due to heat exposure. Conventional pasteurization remains widely used in the food industry for its effectiveness and simplicity despite potential quality degradation.

Key Differences Between HPP and Pasteurization

High Pressure Processing (HPP) uses extreme pressure to inactivate bacteria and enzymes while preserving the food's original flavor, texture, and nutrients, unlike Pasteurization, which relies on heat to kill pathogens, often affecting taste and nutritional value. HPP is a non-thermal method, making it ideal for fresh juices, meats, and ready-to-eat meals, whereas Pasteurization is commonly used for dairy, milk, and canned products to ensure safety through thermal treatment. Understanding these key differences helps you choose the best preservation method for maintaining food quality and extending shelf life.

Impact on Nutritional Value

High Pressure Processing (HPP) preserves more vitamins, antioxidants, and enzymes compared to traditional pasteurization due to its non-thermal method, which minimizes nutrient degradation. Pasteurization, involving heat, often reduces heat-sensitive nutrients such as vitamin C and B vitamins, impacting overall nutritional quality. Studies show HPP-treated foods retain higher levels of bioactive compounds, supporting better nutrient absorption and health benefits.

Effects on Flavor and Texture

High Pressure Processing (HPP) preserves the fresh, natural flavor and crisp texture of foods by inactivating microbes without heat, maintaining the original sensory qualities better than traditional pasteurization. Pasteurization uses heat, which can alter flavor profiles by creating cooked or caramelized notes and may soften textures due to protein denaturation. You can expect products treated with HPP to retain more of their authentic taste and firm texture compared to those undergoing heat pasteurization.

Food Safety and Microbial Reduction

HPP (High Pressure Processing) uses extreme pressure to inactivate pathogens and spoilage microorganisms without heat, preserving food quality while ensuring safety. Pasteurization relies on thermal treatment to kill harmful microbes, which can sometimes alter flavor and nutrients. Choosing HPP or pasteurization for microbial reduction depends on your food's texture, shelf life requirements, and safety standards.

Shelf Life Comparison

High Pressure Processing (HPP) extends product shelf life significantly longer than traditional pasteurization by inactivating pathogens and spoilage microorganisms without the use of heat. Unlike pasteurization, which typically allows a shelf life of a few weeks under refrigeration, HPP-treated products can maintain freshness and safety for several months. Your choice between HPP and pasteurization impacts storage duration and product quality, with HPP offering superior shelf life retention.

Environmental and Energy Considerations

High Pressure Processing (HPP) consumes less energy compared to traditional pasteurization because it operates at ambient temperatures, reducing the need for prolonged heating and cooling cycles. HPP's cold pasteurization method also minimizes greenhouse gas emissions by lowering fossil fuel usage associated with heating water and equipment. Overall, HPP offers a more sustainable and eco-friendly alternative to conventional thermal pasteurization by decreasing energy consumption and environmental impact in food processing.

Choosing the Right Method for Your Food Product

HPP (High Pressure Processing) preserves the fresh taste and nutrients of your food by using intense pressure to eliminate pathogens without heat, making it ideal for sensitive or fresh products like juices and deli meats. Pasteurization relies on heat treatment to kill harmful microorganisms but may alter the texture and nutritional content, better suited for dairy products and shelf-stable items. Understanding your product's sensitivity to heat, shelf life requirements, and target market can guide the choice between HPP and pasteurization for optimal safety and quality.

HPP vs Pasteurization Infographic

libmatt.com

libmatt.com