UHT (Ultra-High Temperature) processing heats milk or other liquids above 135degC for a few seconds to extend shelf life without refrigeration, while HTST (High-Temperature Short Time) heating typically uses around 72degC for 15 seconds to preserve freshness with a shorter shelf life. Your choice between UHT and HTST depends on whether you prioritize longer storage without refrigeration or maintaining a fresher taste with refrigerated storage.

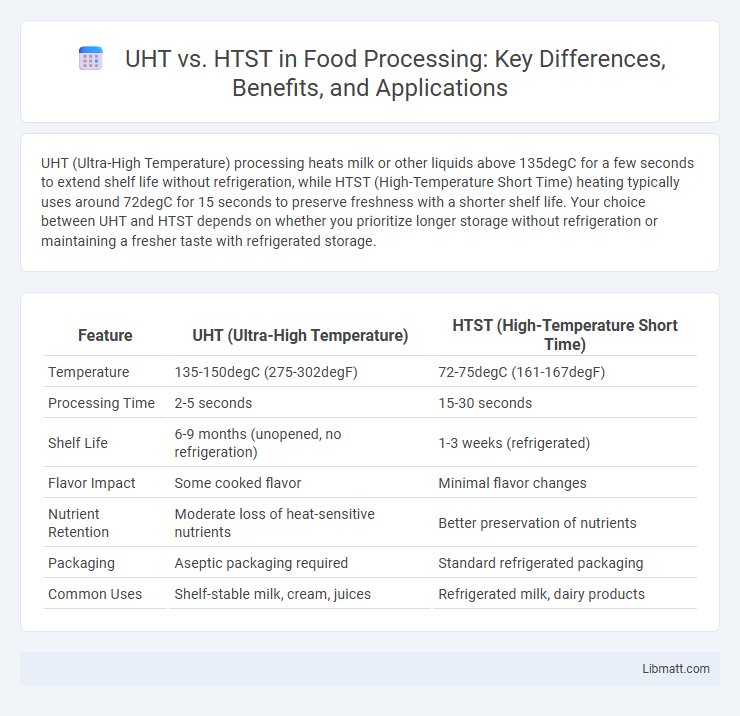

Table of Comparison

| Feature | UHT (Ultra-High Temperature) | HTST (High-Temperature Short Time) |

|---|---|---|

| Temperature | 135-150degC (275-302degF) | 72-75degC (161-167degF) |

| Processing Time | 2-5 seconds | 15-30 seconds |

| Shelf Life | 6-9 months (unopened, no refrigeration) | 1-3 weeks (refrigerated) |

| Flavor Impact | Some cooked flavor | Minimal flavor changes |

| Nutrient Retention | Moderate loss of heat-sensitive nutrients | Better preservation of nutrients |

| Packaging | Aseptic packaging required | Standard refrigerated packaging |

| Common Uses | Shelf-stable milk, cream, juices | Refrigerated milk, dairy products |

Introduction to UHT and HTST Pasteurization

UHT (Ultra-High Temperature) and HTST (High-Temperature Short Time) pasteurization are two heat-treatment methods primarily used to ensure the safety and extend the shelf life of dairy products. UHT involves heating products to around 135-150degC for 2-5 seconds, effectively sterilizing and making milk shelf-stable without refrigeration for several months. HTST pasteurization heats milk to 72degC for 15 seconds, preserving more fresh taste while reducing microbial load for refrigerated storage.

Definition and Process of UHT Pasteurization

UHT (Ultra-High Temperature) pasteurization involves rapidly heating milk or other liquids to at least 135degC (275degF) for 2 to 5 seconds to eliminate harmful bacteria and extend shelf life. This process differs from HTST (High-Temperature Short Time) pasteurization, which heats liquid to 72degC (161degF) for 15 seconds. UHT's rapid heating and aseptic packaging ensure your dairy products remain fresh without refrigeration for several months.

Definition and Process of HTST Pasteurization

HTST pasteurization, or High-Temperature Short-Time pasteurization, involves heating milk to at least 72degC (161degF) for 15 seconds to eliminate pathogenic microorganisms while preserving quality. This process uses rapid heating and cooling techniques to minimize nutrient loss and maintain flavor integrity compared to longer or higher-heat treatments. For your dairy products, HTST ensures safety with minimal impact on taste and nutritional value, making it ideal for fresh milk consumption.

Key Differences Between UHT and HTST

UHT (Ultra-High Temperature) processing heats milk to 135-150degC for 2-5 seconds, resulting in extended shelf life without refrigeration, while HTST (High-Temperature Short-Time) heats milk to 72degC for 15 seconds, primarily targeting pasteurization to kill pathogens with shorter shelf life. UHT sterilizes products through intense heat and rapid cooling, preserving taste and nutrients, whereas HTST maintains more natural flavor but requires cold storage. Your choice depends on storage needs and desired product freshness, with UHT suitable for long-term storage and HTST for fresher dairy consumption.

Impact on Nutritional Content

UHT (Ultra-High Temperature) processing exposes milk to temperatures above 135degC for a few seconds, which results in minimal loss of vitamins but can slightly reduce heat-sensitive nutrients like vitamin B12 and folate. HTST (High-Temperature Short Time) pasteurization heats milk to 72degC for 15 seconds, preserving more of the sensory qualities and most heat-sensitive nutrients while effectively reducing microbial load. Both methods impact nutritional content differently, with UHT offering longer shelf life but slightly altered nutrient profiles compared to HTST.

Effects on Flavor and Texture

UHT (Ultra High Temperature) processing results in a slightly cooked flavor and a smoother texture due to rapid heating at temperatures above 135degC for a few seconds. HTST (High Temperature Short Time) preserves more of the milk's natural flavor and creaminess by heating at 72degC for 15 seconds, maintaining a fresher taste and slightly firmer texture. Your choice between UHT and HTST impacts the flavor intensity and mouthfeel of dairy products, with UHT offering longer shelf life but altered sensory qualities.

Shelf Life Comparison

UHT (Ultra-High Temperature) processing extends shelf life significantly, allowing products to stay fresh for 6 to 9 months without refrigeration, compared to HTST (High-Temperature Short Time), which typically extends shelf life by only 2 to 3 weeks under refrigerated conditions. This difference is due to UHT's ability to sterilize by heating milk above 135degC for a few seconds, destroying more spores and bacteria than HTST's 72degC for 15 seconds. Understanding shelf life comparison helps you choose the right processing method based on your storage and distribution needs.

Safety and Microbial Elimination

UHT (Ultra-High Temperature) processing heats milk to 135-150degC for 2-5 seconds, ensuring near-complete microbial elimination and extended shelf life without refrigeration. HTST (High Temperature Short Time) involves heating milk to 72degC for 15 seconds, effectively reducing common pathogens but requiring refrigeration to prevent microbial growth post-processing. UHT provides superior safety through sterilization, while HTST relies on pasteurization to maintain microbial control, balancing taste and storage needs.

Environmental and Economic Considerations

UHT (Ultra High Temperature) processing requires less energy per liter of milk due to its shorter processing time compared to HTST (High Temperature Short Time), reducing greenhouse gas emissions and operational costs. However, UHT's higher initial equipment investment and packaging requirements can increase upfront expenses, while HTST systems, though more energy-intensive over time, benefit from lower packaging costs using traditional dairy cartons. Choosing between UHT and HTST impacts environmental footprint and economic efficiency, influenced by production scale, energy sources, and supply chain logistics.

Choosing the Right Pasteurization Method

Choosing the right pasteurization method depends on the desired shelf life, flavor retention, and nutrient preservation of dairy products. Ultra-High Temperature (UHT) pasteurization heats milk above 135degC for 2-5 seconds, extending shelf life up to 6 months without refrigeration but slightly altering taste. High-Temperature Short-Time (HTST) pasteurization, typically at 72degC for 15 seconds, maintains more natural flavor and nutrients but requires refrigeration and offers a shorter shelf life of 2-3 weeks.

UHT vs HTST Infographic

libmatt.com

libmatt.com