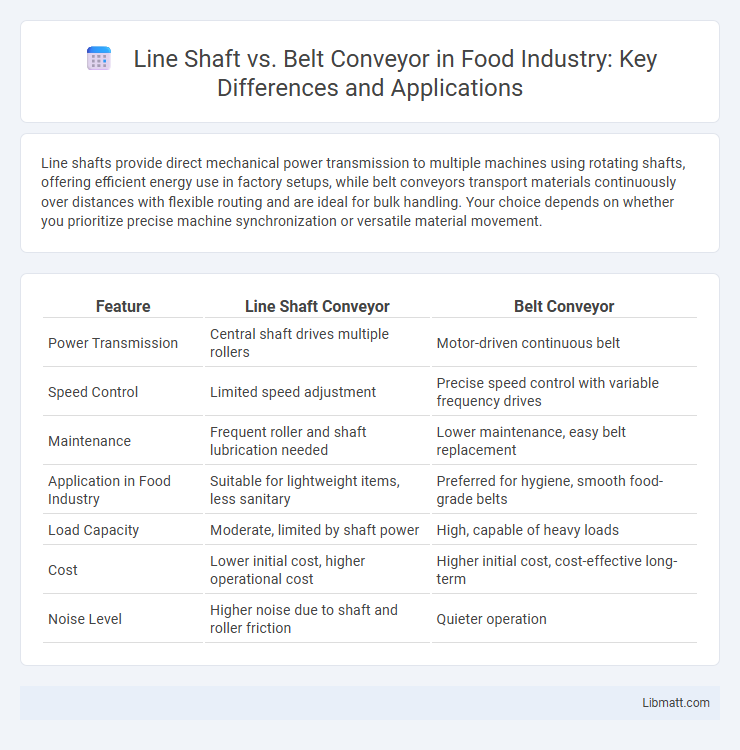

Line shafts provide direct mechanical power transmission to multiple machines using rotating shafts, offering efficient energy use in factory setups, while belt conveyors transport materials continuously over distances with flexible routing and are ideal for bulk handling. Your choice depends on whether you prioritize precise machine synchronization or versatile material movement.

Table of Comparison

| Feature | Line Shaft Conveyor | Belt Conveyor |

|---|---|---|

| Power Transmission | Central shaft drives multiple rollers | Motor-driven continuous belt |

| Speed Control | Limited speed adjustment | Precise speed control with variable frequency drives |

| Maintenance | Frequent roller and shaft lubrication needed | Lower maintenance, easy belt replacement |

| Application in Food Industry | Suitable for lightweight items, less sanitary | Preferred for hygiene, smooth food-grade belts |

| Load Capacity | Moderate, limited by shaft power | High, capable of heavy loads |

| Cost | Lower initial cost, higher operational cost | Higher initial cost, cost-effective long-term |

| Noise Level | Higher noise due to shaft and roller friction | Quieter operation |

Introduction to Line Shaft and Belt Conveyors

Line shaft conveyors use a single rotating shaft powered by a motor to drive multiple rollers, providing efficient material transport in various industries. Belt conveyors consist of a continuous belt looped over pulleys, ideal for moving bulk or packaged materials smoothly over long distances. Your choice between these conveyor types depends on factors like load size, distance, and application requirements.

Basic Working Principles

Line shaft conveyors operate using a rotating shaft powered by a single motor, with pulleys transferring motion to individual rollers through belts, enabling synchronized movement along the conveyor line. Belt conveyors consist of a continuous looped belt driven by pulleys at either end, supporting and moving materials directly on the belt surface for efficient transport. Understanding these basic working principles helps you select the appropriate conveyor type for your material handling needs.

Key Differences Between Line Shaft and Belt Conveyors

Line shaft conveyors use a rotating shaft to drive the rollers directly, enabling efficient movement of light to medium-weight products in packaging and distribution applications. Belt conveyors transport products on a continuous belt powered by motors, offering higher load capacity and smooth handling of bulky or irregular items. Key differences include power transmission method, load capacity, and suitability for specific product types and conveyor layouts.

Application Scenarios and Industries

Line shaft conveyors excel in lightweight assembly, packaging, and manufacturing industries where precise control and compact layouts are essential. Belt conveyors are ideal for bulk material handling across mining, agriculture, and food processing sectors due to their high capacity and ability to transport diverse materials over long distances. Your choice depends on operational needs like load type, speed, and spatial constraints within your production environment.

Advantages of Line Shaft Conveyors

Line shaft conveyors offer several advantages, including low power consumption and quiet operation, making them ideal for environments requiring minimal noise and energy efficiency. Their simple design allows for easy maintenance and installation, reducing downtime and operational costs. You benefit from their versatility in handling a wide range of products, enhancing productivity in manufacturing and packaging processes.

Advantages of Belt Conveyors

Belt conveyors offer superior flexibility in handling various types of materials, including bulk, unit, and packaged products, making them suitable for diverse industrial applications. They provide continuous, efficient material flow with low noise levels and minimal maintenance requirements, resulting in reduced operational downtime and cost savings. Their ability to cover long distances and navigate complex layouts gives belt conveyors a significant advantage over line shafts in optimizing production line efficiency.

Limitations and Drawbacks

Line shafts suffer from high maintenance due to frequent bearing wear and alignment issues, leading to increased downtime and operational costs. Belt conveyors face limitations in handling heavy or abrasive materials, which can cause belt damage and frequent replacements. Both systems may struggle with energy inefficiency, but belt conveyors generally offer better scalability for longer distances despite their susceptibility to slippage and tracking problems.

Cost Comparison and Maintenance

Line shafts typically incur higher initial installation costs due to complex mechanical components, while belt conveyors offer a cost-effective solution with simpler setup and scalability. Maintenance expenses for line shafts are generally greater because of frequent lubrication, shaft alignment, and bearing replacements, whereas belt conveyors demand regular belt tension checks and pulley inspections but less intensive upkeep. Overall, belt conveyors present lower lifetime maintenance costs and reduced operational downtime compared to line shaft systems.

Factors to Consider When Choosing

When choosing between a line shaft and a belt conveyor, consider factors such as load capacity, speed control, and installation complexity. Line shaft conveyors offer precise speed regulation and are ideal for moderate loads, while belt conveyors excel in handling heavier materials and providing continuous movement. Evaluate maintenance requirements and energy consumption to ensure optimal operational efficiency for your specific application.

Future Trends in Conveyor Technology

Future trends in conveyor technology emphasize increased automation, energy efficiency, and smart integration, with belt conveyors adopting IoT sensors and predictive maintenance systems to minimize downtime and optimize performance. Line shaft conveyors continue to evolve with quieter, more compact designs and enhanced safety features, making them suitable for sensitive applications and smaller spaces. Your facility can benefit from these advancements by selecting conveyors that improve throughput while reducing operational costs and environmental impact.

Line Shaft vs Belt Conveyor Infographic

libmatt.com

libmatt.com