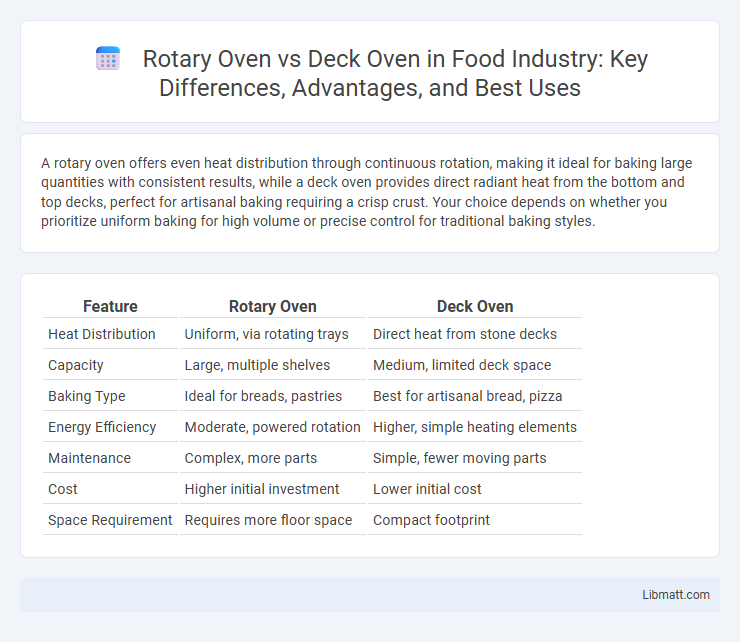

A rotary oven offers even heat distribution through continuous rotation, making it ideal for baking large quantities with consistent results, while a deck oven provides direct radiant heat from the bottom and top decks, perfect for artisanal baking requiring a crisp crust. Your choice depends on whether you prioritize uniform baking for high volume or precise control for traditional baking styles.

Table of Comparison

| Feature | Rotary Oven | Deck Oven |

|---|---|---|

| Heat Distribution | Uniform, via rotating trays | Direct heat from stone decks |

| Capacity | Large, multiple shelves | Medium, limited deck space |

| Baking Type | Ideal for breads, pastries | Best for artisanal bread, pizza |

| Energy Efficiency | Moderate, powered rotation | Higher, simple heating elements |

| Maintenance | Complex, more parts | Simple, fewer moving parts |

| Cost | Higher initial investment | Lower initial cost |

| Space Requirement | Requires more floor space | Compact footprint |

Introduction to Rotary Ovens and Deck Ovens

Rotary ovens feature rotating racks that ensure even heat distribution, making them ideal for baking large batches of bread, pastries, and cakes uniformly. Deck ovens heat through stone or metal decks, providing consistent bottom heat that enhances crust quality, preferred for artisan breads and pizzas. Both ovens cater to different baking needs, with rotary ovens excelling in volume and deck ovens offering superior crust development.

How Rotary Ovens Work

Rotary ovens use a rotating rack system inside a convection oven, allowing even heat distribution and consistent baking results by gently tumbling products as they cook. This mechanism ensures uniform exposure to hot air, which is ideal for baking large batches of bread, pastries, and other bakery goods with consistent texture and color. Your bakery operations benefit from increased efficiency and scalability due to the rotary oven's ability to handle diverse product loads with minimal monitoring.

How Deck Ovens Work

Deck ovens work by using stone or steel decks that evenly distribute heat directly to the food, creating a consistent baking environment ideal for bread and pizzas. Heat sources located beneath or above the decks ensure high temperatures and moisture retention, producing a crisp crust while maintaining a soft interior. Your baking results benefit from precise temperature control and the ability to bake multiple items simultaneously on separate decks.

Key Differences Between Rotary and Deck Ovens

Rotary ovens feature a rotating rack system that ensures even heat distribution and consistent baking, making them ideal for large-scale production of bread and pastries. Deck ovens use stationary, stone or metal baking surfaces stacked in decks, offering direct heat and superior crust formation, preferred for artisan breads and pizzas. The main differences lie in their heat delivery methods, capacity, and suitability for various baking products, with rotary ovens excelling in volume and uniformity while deck ovens provide precise temperature control and texture.

Energy Efficiency Comparison

Rotary ovens typically offer higher energy efficiency due to their continuous rotation, which ensures even heat distribution and reduces baking time, leading to lower energy consumption. Deck ovens, while effective for certain baking tasks, often require longer preheating and baking periods, resulting in increased energy use. Understanding these differences can help you choose the most energy-efficient oven for your bakery operations.

Baking Performance and Results

Rotary ovens provide consistent heat distribution through rotating racks, ensuring even baking and uniform color on baked goods, which is ideal for high-volume production. Deck ovens offer excellent steam retention and precise temperature control, resulting in superior crust development and artisan-quality bread. Both ovens excel in baking performance, but rotary ovens are preferred for large-scale uniformity, while deck ovens shine in producing traditional bakery textures and flavors.

Space and Installation Requirements

Rotary ovens require more space due to their rotating racks and larger footprint, making them better suited for commercial bakeries with ample room. Deck ovens have a compact design with stackable units, optimizing installation in smaller bakeries or kitchens with limited floor space. Your choice depends on available space and installation ease to maximize kitchen efficiency.

Maintenance and Durability

Rotary ovens feature complex moving parts requiring regular lubrication and calibration to maintain optimal performance, while deck ovens have simpler, stationary components that generally demand less frequent maintenance. The durable construction of deck ovens, often with heavy-duty stone or brick decks, supports long-term heat retention and consistent baking, enhancing their lifespan in commercial settings. Maintenance for rotary ovens can be more intensive due to rotating racks and airflow systems, but they excel in even baking and capacity, balancing wear with operational efficiency.

Cost Analysis: Initial and Operational

Rotary ovens typically demand a higher initial investment due to their complex design and advanced technology, while deck ovens offer a more affordable upfront cost with simpler construction. Operational expenses for rotary ovens can be greater because of increased energy consumption and maintenance needs, whereas deck ovens generally have lower energy requirements and reduced upkeep costs. Understanding your production scale and budget will help you determine which oven type aligns best with your financial goals.

Choosing the Right Oven for Your Bakery

Rotary ovens provide consistent heat circulation, ideal for high-volume bakeries requiring uniform baking of bread and pastries. Deck ovens offer direct radiant heat, perfect for artisan loaves and pizza with a crispy crust and traditional texture. Selecting the right oven depends on your bakery's production scale, desired product quality, and energy efficiency needs.

rotary oven vs deck oven Infographic

libmatt.com

libmatt.com