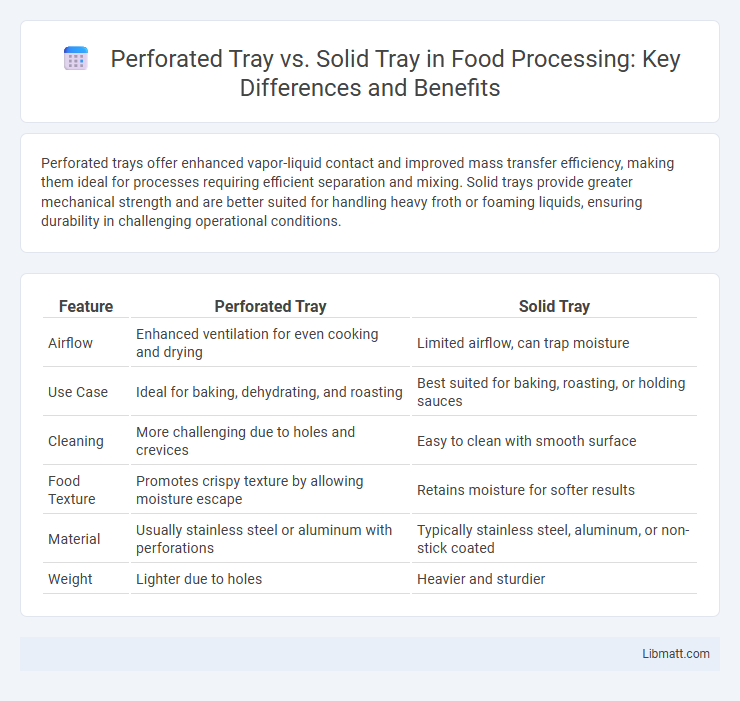

Perforated trays offer enhanced vapor-liquid contact and improved mass transfer efficiency, making them ideal for processes requiring efficient separation and mixing. Solid trays provide greater mechanical strength and are better suited for handling heavy froth or foaming liquids, ensuring durability in challenging operational conditions.

Table of Comparison

| Feature | Perforated Tray | Solid Tray |

|---|---|---|

| Airflow | Enhanced ventilation for even cooking and drying | Limited airflow, can trap moisture |

| Use Case | Ideal for baking, dehydrating, and roasting | Best suited for baking, roasting, or holding sauces |

| Cleaning | More challenging due to holes and crevices | Easy to clean with smooth surface |

| Food Texture | Promotes crispy texture by allowing moisture escape | Retains moisture for softer results |

| Material | Usually stainless steel or aluminum with perforations | Typically stainless steel, aluminum, or non-stick coated |

| Weight | Lighter due to holes | Heavier and sturdier |

Introduction to Perforated and Solid Trays

Perforated trays feature evenly spaced openings allowing improved vapor-liquid contact and efficient mass transfer in distillation columns. Solid trays, being flat and impermeable, provide support and distribution of liquid but rely on alternative methods, such as downcomers, to handle vapor flow. Selecting between perforated and solid trays depends on factors like column design, pressure drop, and specific process requirements.

Key Differences Between Perforated and Solid Trays

Perforated trays feature evenly spaced holes allowing improved vapor-liquid contact and enhanced mass transfer efficiency in distillation or absorption columns. Solid trays provide greater mechanical strength and support but limit fluid flow, causing potential pressure drop issues in processes requiring higher throughput. Your selection depends on balancing tray vapor handling capacity, mechanical stability, and specific operational requirements in industrial applications.

Material Options for Perforated and Solid Trays

Perforated trays are commonly manufactured from stainless steel, aluminum, and galvanized steel, offering corrosion resistance and durability ideal for industrial applications. Solid trays are typically made from stainless steel, mild steel, and plastic composites, providing robust support and chemical resistance for diverse process conditions. Material selection for both trays depends on factors like temperature, chemical exposure, and load capacity to optimize performance and longevity.

Advantages of Perforated Trays

Perforated trays offer superior gas-liquid contact efficiency compared to solid trays, enhancing mass transfer performance in distillation and absorption processes. They provide better liquid hold-up and improved vapor distribution, reducing channeling and ensuring uniform phase interaction throughout the column. Your process benefits from increased throughput and reduced pressure drop, making perforated trays ideal for high-capacity separation tasks.

Benefits of Using Solid Trays

Solid trays offer enhanced liquid retention and better vapor-liquid contact compared to perforated trays, improving mass transfer efficiency in distillation and absorption processes. They provide superior mechanical strength and durability, reducing maintenance costs and downtime in industrial applications. Solid trays also minimize fouling and plugging issues, ensuring more consistent operation in challenging process conditions.

Common Applications for Perforated Trays

Perforated trays are widely used in chemical processing and distillation columns where efficient vapor-liquid contact is essential for separation and reaction. These trays facilitate better fluid distribution and minimize pressure drop, making them ideal for applications such as absorption, stripping, and rectification. Your choice of perforated trays enhances mass transfer efficiency in systems requiring controlled phase interactions.

Typical Uses for Solid Trays

Solid trays are commonly used in distillation and absorption processes where liquid mixing without vapor-liquid contact is essential, such as in reactive absorption or certain stripping operations. Their design prevents vapor flow through the tray, making them ideal for applications requiring liquid holding or redistribution. You benefit from solid trays when precise liquid handling and retention are critical to process efficiency.

Factors to Consider When Choosing Between Perforated and Solid Trays

Choosing between perforated and solid trays depends on factors such as airflow requirements, product stability, and application type. Perforated trays allow better ventilation and drying, ideal for processes needing uniform air distribution, while solid trays provide enhanced support for fragile or liquid-containing items. Material compatibility, load capacity, and ease of cleaning also influence the decision based on operational needs.

Maintenance and Cleaning: Perforated vs Solid Trays

Perforated trays facilitate easier maintenance and cleaning due to their open design, allowing debris and residues to be easily washed away and preventing buildup. Solid trays, while more prone to accumulation of dirt and liquids, require more frequent manual scrubbing and inspection to ensure hygiene and functionality. Choosing perforated trays reduces downtime and labor costs associated with cleaning compared to solid trays in industrial and food processing applications.

Conclusion: Which Tray is Best for Your Needs?

Choosing between a perforated tray and a solid tray depends on your specific process requirements, such as mass transfer efficiency, pressure drop, and liquid distribution. Perforated trays offer superior gas-liquid contact and are ideal for applications demanding high vapor throughput and separation efficiency, while solid trays provide simpler construction and are better suited for operations with lower vapor flow or fouling concerns. Assessing your operational conditions and desired outcomes will help determine which tray best meets your process needs.

Perforated Tray vs Solid Tray Infographic

libmatt.com

libmatt.com