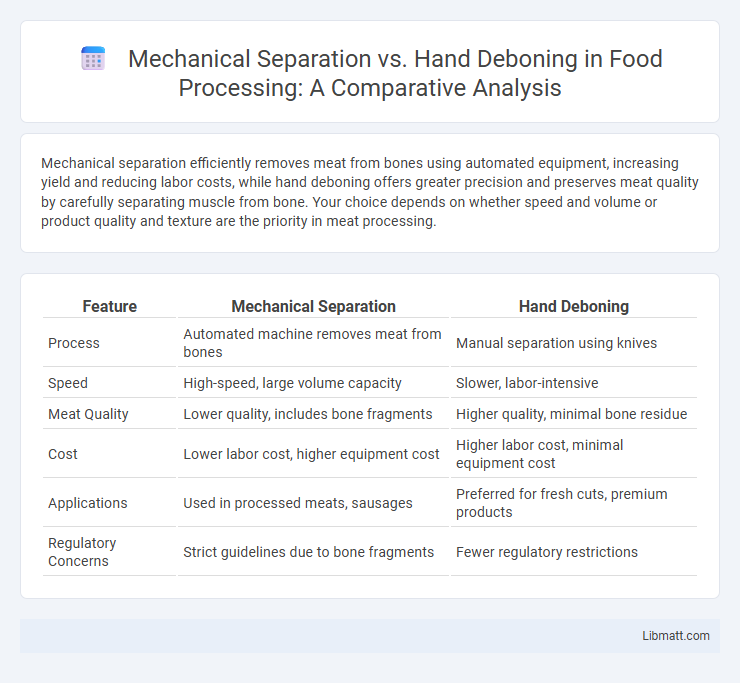

Mechanical separation efficiently removes meat from bones using automated equipment, increasing yield and reducing labor costs, while hand deboning offers greater precision and preserves meat quality by carefully separating muscle from bone. Your choice depends on whether speed and volume or product quality and texture are the priority in meat processing.

Table of Comparison

| Feature | Mechanical Separation | Hand Deboning |

|---|---|---|

| Process | Automated machine removes meat from bones | Manual separation using knives |

| Speed | High-speed, large volume capacity | Slower, labor-intensive |

| Meat Quality | Lower quality, includes bone fragments | Higher quality, minimal bone residue |

| Cost | Lower labor cost, higher equipment cost | Higher labor cost, minimal equipment cost |

| Applications | Used in processed meats, sausages | Preferred for fresh cuts, premium products |

| Regulatory Concerns | Strict guidelines due to bone fragments | Fewer regulatory restrictions |

Introduction to Meat Processing Techniques

Mechanical separation in meat processing uses high-pressure machinery to efficiently extract meat from bones, maximizing yield with minimal manual labor. Hand deboning, a traditional technique, relies on skilled workers to carefully remove meat, preserving texture and quality often preferred for premium products. Both methods play essential roles in the industry, balancing productivity and product standards.

Understanding Mechanical Separation

Mechanical separation uses high-speed machinery to strip meat from bones, maximizing yield and efficiency compared to traditional hand deboning. This process involves crushing and pressing bones to extract residual meat, which is then used in processed products like sausages or nuggets. Understanding mechanical separation helps you make informed choices about meat quality, texture, and nutritional content in your food products.

Overview of Hand Deboning

Hand deboning involves the manual removal of meat from bones using knives and precision tools, ensuring minimal damage to muscle fibers. This traditional method preserves the texture and quality of the meat, making it preferred for premium cuts and specialty products. Despite being labor-intensive and time-consuming compared to mechanical separation, hand deboning offers superior control over yield and product appearance.

Efficiency Comparison: Speed and Output

Mechanical separation dramatically increases efficiency by processing large quantities of meat faster than hand deboning, delivering higher output in less time. Hand deboning offers precise control, ideal for delicate cuts, but is significantly slower and labor-intensive compared to automated systems. Your choice depends on balancing speed and yield requirements with product quality preferences.

Yield and Meat Quality Analysis

Mechanical separation offers higher yield by extracting more meat from bones compared to hand deboning, which results in less residual meat left on the skeletal structure. However, hand deboning typically produces superior meat quality, with a better texture and lower fat content, suitable for premium products. You should balance the choice between yield and meat quality depending on your specific production goals and product requirements.

Food Safety and Contamination Risks

Mechanical separation reduces manual handling, lowering direct contamination risks but may increase the chance of bone fragments and metal debris in meat products. Hand deboning allows better visual inspection, minimizing cross-contamination and ensuring higher food safety standards through careful removal of contaminants. Your choice between these methods impacts the balance between efficiency and the level of control over contamination risks.

Cost Implications for Producers

Mechanical separation significantly reduces labor costs for producers by automating the extraction of meat from bones, increasing processing speed and output. Hand deboning, while more expensive due to higher labor requirements, offers superior product quality and less bone fragment contamination, which can justify the investment for premium markets. You must weigh the initial equipment costs against long-term operational savings and product quality demands when choosing the optimal method.

Impact on Nutritional Value

Mechanical separation retains more residual meat from bones compared to hand deboning, often resulting in higher protein yields but potentially increased fat and bone particles that can affect purity. Hand deboning maintains better control over meat quality and nutrient composition, preserving natural textures and minimizing contamination from bone marrow and cartilage. Studies show hand-deboned meat has higher retention of key vitamins and minerals, while mechanically separated meat may have altered nutrient profiles due to processing.

Sustainability and Waste Reduction

Mechanical separation significantly enhances sustainability by maximizing meat recovery from animal carcasses, reducing food waste compared to traditional hand deboning. This automated process efficiently extracts usable meat from bones and connective tissues, minimizing leftover scraps that often result from manual methods. Your choice to adopt mechanical separation supports eco-friendly practices by lowering resource consumption and decreasing landfill contributions associated with meat processing waste.

Choosing the Best Method for Your Operation

Mechanical separation offers higher efficiency and yield, ideal for large-scale poultry processing plants seeking to maximize product output and reduce labor costs. Hand deboning provides superior meat quality and texture, making it preferable for premium products where consumer experience and presentation are critical. Selecting the best method depends on operation scale, product quality requirements, and budget constraints to balance efficiency with desired end-product characteristics.

Mechanical Separation vs Hand Deboning Infographic

libmatt.com

libmatt.com