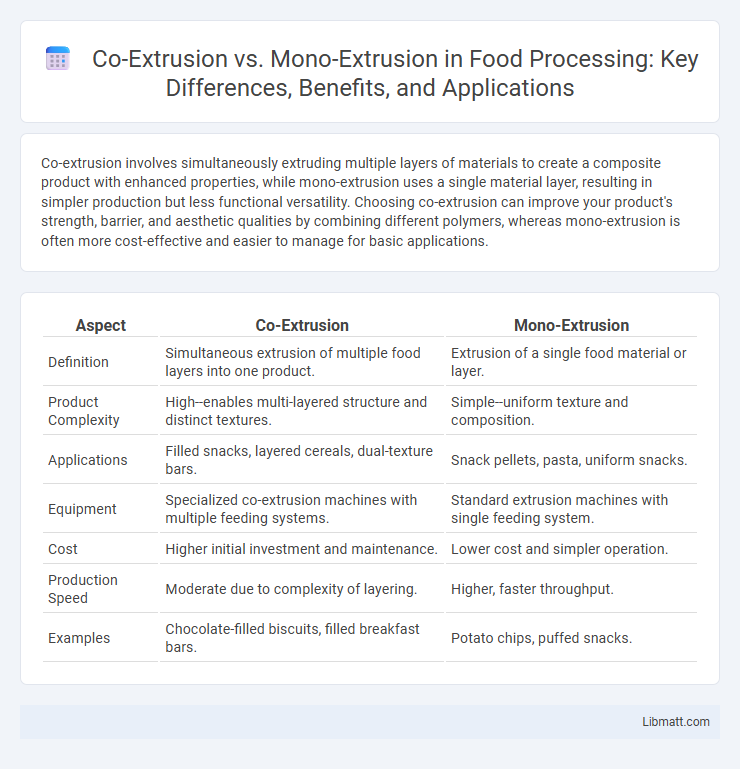

Co-extrusion involves simultaneously extruding multiple layers of materials to create a composite product with enhanced properties, while mono-extrusion uses a single material layer, resulting in simpler production but less functional versatility. Choosing co-extrusion can improve your product's strength, barrier, and aesthetic qualities by combining different polymers, whereas mono-extrusion is often more cost-effective and easier to manage for basic applications.

Table of Comparison

| Aspect | Co-Extrusion | Mono-Extrusion |

|---|---|---|

| Definition | Simultaneous extrusion of multiple food layers into one product. | Extrusion of a single food material or layer. |

| Product Complexity | High--enables multi-layered structure and distinct textures. | Simple--uniform texture and composition. |

| Applications | Filled snacks, layered cereals, dual-texture bars. | Snack pellets, pasta, uniform snacks. |

| Equipment | Specialized co-extrusion machines with multiple feeding systems. | Standard extrusion machines with single feeding system. |

| Cost | Higher initial investment and maintenance. | Lower cost and simpler operation. |

| Production Speed | Moderate due to complexity of layering. | Higher, faster throughput. |

| Examples | Chocolate-filled biscuits, filled breakfast bars. | Potato chips, puffed snacks. |

Introduction to Extrusion Processes

Extrusion processes involve shaping materials by forcing them through a die to create continuous profiles, with co-extrusion combining multiple materials or layers in a single process to enhance product properties like barrier protection and strength. Mono-extrusion uses a single material, providing simplicity and cost-effectiveness but with limited functional versatility. Understanding these differences helps you select the optimal extrusion method for applications ranging from packaging to automotive components.

What is Mono-Extrusion?

Mono-extrusion is a plastic manufacturing process that involves melting and shaping a single type of polymer through one extruder to produce uniform sheets, films, or profiles. This method offers simplicity, cost-efficiency, and consistent material properties, making it ideal for applications requiring a single-layer structure. Your choice of mono-extrusion depends on the need for straightforward production and specific material characteristics without the complexity of combining multiple layers.

What is Co-Extrusion?

Co-extrusion is a manufacturing process that combines two or more layers of different materials into a single, unified product through simultaneous extrusion. This technique allows for enhanced material properties such as improved barrier resistance, strength, and aesthetic appeal by layering specialized polymers or additives. Unlike mono-extrusion, which uses a single material, co-extrusion enables tailored functionality by leveraging the combined benefits of multiple materials in one continuous profile.

Key Differences Between Mono-Extrusion and Co-Extrusion

Mono-extrusion involves a single material melted and shaped through one extruder, producing uniform products ideal for simple applications. Co-extrusion uses multiple extruders to simultaneously process different polymers or materials, resulting in multi-layered structures with enhanced properties such as improved barrier resistance, strength, or aesthetics. The key differences lie in complexity, material versatility, and the ability to combine unique material characteristics within one product.

Advantages of Mono-Extrusion

Mono-extrusion offers advantages such as simplified production processes, lower manufacturing costs, and easier material recycling compared to co-extrusion. Its single-layer structure ensures consistent thickness and uniform material properties, making it ideal for packaging applications requiring strength and clarity. You benefit from faster production speeds and reduced equipment complexity when choosing mono-extrusion for your product needs.

Advantages of Co-Extrusion

Co-extrusion offers enhanced material versatility by combining multiple polymers in a single process, enabling superior barrier properties, improved strength, and customized functionality compared to mono-extrusion. It reduces production costs by integrating diverse layers without additional lamination steps, increasing efficiency in packaging and manufacturing industries. The ability to tailor layer thickness and composition also leads to optimized performance in applications such as food packaging, medical devices, and automotive components.

Material Compatibility in Extrusion Techniques

Co-extrusion allows the combination of multiple materials with varying properties, enabling enhanced barrier protection, improved strength, and tailored functionality in a single product. Mono-extrusion is limited to one material type, restricting the final product's versatility and performance characteristics. Your choice depends on the application requirements, with co-extrusion providing superior material compatibility for complex designs.

Common Applications of Mono-Extrusion and Co-Extrusion

Mono-extrusion is commonly used for producing single-layer films, pipes, and profiles in packaging, agriculture, and construction due to its simplicity and cost-effectiveness. Co-extrusion is favored in applications requiring multilayer structures, such as food packaging, medical devices, and automotive parts, where enhanced barrier properties, flexibility, and durability are crucial. Your choice between mono-extrusion and co-extrusion depends on the performance requirements and complexity of the end product.

Cost Implications: Co-Extrusion vs Mono-Extrusion

Co-extrusion typically involves higher initial equipment costs and more complex setup compared to mono-extrusion, leading to increased capital expenditure. However, co-extrusion offers material savings and enhanced product functionality by combining multiple layers, which can reduce long-term operational expenses. Your choice between co-extrusion and mono-extrusion must balance upfront costs with potential efficiencies and product performance benefits.

Choosing the Right Extrusion Process for Your Project

Selecting the appropriate extrusion process depends on your project's material complexity and performance requirements. Co-extrusion offers the advantage of combining multiple layers with different properties, enhancing functionality such as barrier protection, durability, and aesthetic appeal, while mono-extrusion involves a single material layer suitable for simpler applications. Understanding factors like cost, production speed, and desired product characteristics ensures you choose between co-extrusion and mono-extrusion efficiently.

co-extrusion vs mono-extrusion Infographic

libmatt.com

libmatt.com