A nail joint relies on nails driven into materials to hold them together, offering quick and cost-effective assembly ideal for lightweight or temporary structures. A screw joint provides superior strength and durability by creating a threaded connection that resists pull-out and loosening, making it suitable for your projects requiring long-lasting stability.

Table of Comparison

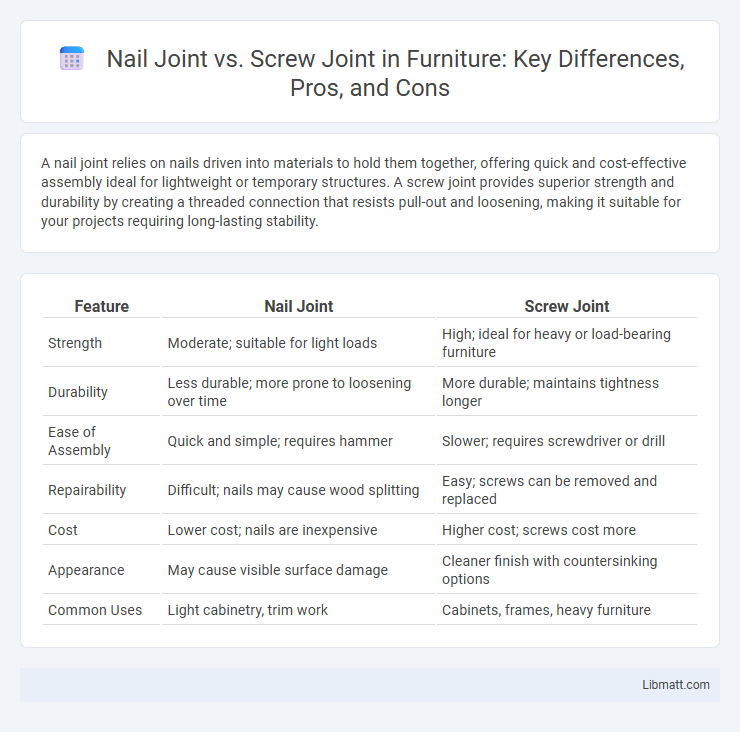

| Feature | Nail Joint | Screw Joint |

|---|---|---|

| Strength | Moderate; suitable for light loads | High; ideal for heavy or load-bearing furniture |

| Durability | Less durable; more prone to loosening over time | More durable; maintains tightness longer |

| Ease of Assembly | Quick and simple; requires hammer | Slower; requires screwdriver or drill |

| Repairability | Difficult; nails may cause wood splitting | Easy; screws can be removed and replaced |

| Cost | Lower cost; nails are inexpensive | Higher cost; screws cost more |

| Appearance | May cause visible surface damage | Cleaner finish with countersinking options |

| Common Uses | Light cabinetry, trim work | Cabinets, frames, heavy furniture |

Introduction to Nail Joints and Screw Joints

Nail joints and screw joints are fundamental techniques used to connect wooden components in construction and woodworking. Nail joints rely on hammer-driven nails to fasten pieces, offering quick assembly and moderate holding strength, while screw joints utilize threaded screws to provide superior grip and resistance to pulling forces. Understanding the differences between these joints helps you select the appropriate fastener for durability, load-bearing capacity, and application-specific requirements.

Key Differences Between Nail and Screw Joints

Nail joints rely on friction and shear strength with smooth-shanked fasteners, making them ideal for quick assembly but less resistant to withdrawal forces. Screw joints feature threaded fasteners that provide superior holding power through mechanical interlocking, enhancing resistance to pull-out and allowing for disassembly. Nail joints are commonly used in framing and rough carpentry, while screw joints excel in applications requiring precision and long-term stability.

Strength and Durability: Nails vs Screws

Screw joints provide greater strength and durability compared to nail joints due to their threaded design, which offers superior holding power and resistance to pull-out forces. Nail joints are more prone to loosening over time under dynamic loads or vibrations, while screws ensure a tighter, long-lasting connection in your woodworking or construction projects. For applications demanding high structural integrity, choosing screws over nails enhances joint stability and longevity.

Application Suitability: When to Use Nails or Screws

Nail joints are ideal for applications requiring quick assembly and shear strength, such as framing and roofing, where holding materials in place without tension is critical. Screw joints offer superior tensile strength and are better suited for projects needing strong, long-lasting connections, like cabinetry or decking, where resistance to pulling forces and ease of disassembly are important. Choosing between nails and screws depends on the load type and the need for durability, with screws favored for precision and structural stability and nails preferred for speed and flexibility.

Installation Process: Nails Compared to Screws

Nail joints involve quickly driving nails into materials using a hammer or nail gun, offering fast and efficient installation ideal for framing and rough carpentry. Screw joints require pre-drilling pilot holes or using power drills to drive screws, providing a more secure and adjustable connection suitable for fine woodworking and applications needing higher holding power. Your choice depends on the desired strength, precision, and installation speed, with nails favoring speed and screws prioritizing stability.

Cost Comparison: Nails versus Screws

Nail joints generally offer a lower cost compared to screw joints due to the cheaper price of nails and faster installation time, making them ideal for large-scale projects with budget constraints. Screws, while more expensive per unit, provide superior holding strength and reduced risk of loosening, which can reduce long-term maintenance costs in high-stress applications. When balancing initial expense and durability, choosing between nail joints and screw joints depends on the specific requirements of the construction project and material compatibility.

Holding Power: Which Joint Lasts Longer?

Screw joints typically offer superior holding power compared to nail joints due to their threaded design, which provides greater resistance to pull-out forces and ensures a tighter connection. Nail joints may loosen over time with vibration or wood movement, leading to reduced joint longevity. For projects requiring durable and long-lasting fastening, your best choice is a screw joint.

Common Uses for Nail and Screw Joints

Nail joints are commonly used in framing, roofing, and wood paneling due to their quick installation and strong shear strength, making them ideal for joining thinner materials and temporary structures. Screw joints provide superior holding power and resistance to withdrawal, making them preferable for cabinetry, furniture assembly, and projects requiring long-lasting, load-bearing connections. When deciding between the two, your choice depends on the application's strength needs, material thickness, and whether the joint must withstand tension or shear forces.

Pros and Cons of Nail Joints

Nail joints offer quick installation and cost-effectiveness making them ideal for light-duty applications or temporary structures. They provide decent shear strength but lack the holding power and precision alignment of screw joints, which can result in loosening under heavy or repetitive loads. Your choice depends on balancing ease of use and load requirements, with nail joints suitable for speed but less reliable for long-term durability.

Pros and Cons of Screw Joints

Screw joints offer superior strength and durability compared to nail joints, providing better resistance to shear and pull-out forces, making them ideal for heavy-duty applications. They allow for easy disassembly and adjustment, which enhances maintenance and repair efficiency. However, screw joints can be time-consuming to install and may require pre-drilling to prevent wood splitting, increasing the overall labor and material costs of your project.

nail joint vs screw joint Infographic

libmatt.com

libmatt.com