Borofloat glass offers excellent thermal resistance and mechanical durability, making it ideal for laboratory glassware and cookware, while quartz glass provides superior optical clarity and higher temperature tolerance, perfect for semiconductor manufacturing and UV optics. Your choice depends on the required thermal properties, chemical resistance, and optical performance for your specific application.

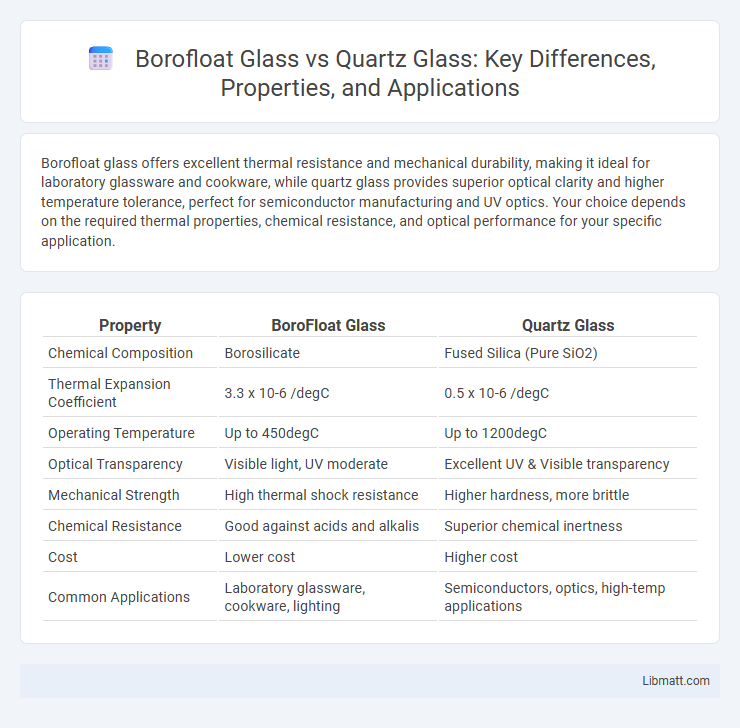

Table of Comparison

| Property | BoroFloat Glass | Quartz Glass |

|---|---|---|

| Chemical Composition | Borosilicate | Fused Silica (Pure SiO2) |

| Thermal Expansion Coefficient | 3.3 x 10-6 /degC | 0.5 x 10-6 /degC |

| Operating Temperature | Up to 450degC | Up to 1200degC |

| Optical Transparency | Visible light, UV moderate | Excellent UV & Visible transparency |

| Mechanical Strength | High thermal shock resistance | Higher hardness, more brittle |

| Chemical Resistance | Good against acids and alkalis | Superior chemical inertness |

| Cost | Lower cost | Higher cost |

| Common Applications | Laboratory glassware, cookware, lighting | Semiconductors, optics, high-temp applications |

Introduction to Borofloat Glass and Quartz Glass

Borofloat glass is a type of borosilicate glass known for its high thermal resistance, low thermal expansion coefficient (approximately 3.3 x 10^-6 /degC), and excellent chemical durability, commonly used in laboratory glassware and industrial applications. Quartz glass, composed of nearly pure silicon dioxide (SiO2), offers superior optical clarity, extremely high melting point (about 1,650degC), and exceptional ultraviolet light transmission, making it ideal for semiconductor and photonics industries. Both materials provide unique benefits: Borofloat is favored for mechanical strength and thermal shock resistance, while quartz glass excels in optical performance and purity.

Key Chemical Compositions

Borofloat glass primarily consists of approximately 80% silica (SiO2) with boron oxide (B2O3) making up around 13%, along with smaller amounts of sodium oxide (Na2O) and aluminum oxide (Al2O3). Quartz glass is nearly pure silica, containing over 99% SiO2, with minimal impurities and no significant boron content. Your choice between these materials should consider the higher thermal resistance and chemical purity of quartz glass versus the improved thermal shock resistance and easier manufacturability of borofloat glass.

Thermal Properties Comparison

Borofloat glass exhibits a low coefficient of thermal expansion around 3.3 x 10^-6 /degC, allowing it to withstand rapid temperature changes and thermal shock up to approximately 500degC. Quartz glass offers superior thermal stability with an extremely low thermal expansion coefficient near 0.5 x 10^-6 /degC and can endure temperatures exceeding 1,000degC without deformation. The choice between Borofloat and quartz glass depends on application-specific thermal resistance needs, with quartz providing higher temperature tolerance and Borofloat offering cost-effective thermal shock resistance.

Optical Clarity and Light Transmission

Borofloat glass offers excellent optical clarity with high light transmission rates of approximately 90%, making it ideal for applications requiring clear visualization and minimal distortion. Quartz glass surpasses Borofloat in ultraviolet light transmission, maintaining over 90% transmittance down to 200 nm, critical for high-precision optical and UV-sensitive processes. Both materials provide excellent optical properties, but quartz glass is preferred where UV transparency and superior optical clarity are essential.

Mechanical Strength and Durability

Borofloat glass offers high mechanical strength and excellent thermal shock resistance due to its borosilicate composition, making it suitable for applications requiring durability under rapid temperature changes. Quartz glass exhibits superior hardness and exceptional durability against chemical corrosion, maintaining structural integrity at extreme temperatures above 1000degC. While borofloat glass balances strength and thermal stability for everyday use, quartz glass is preferred for high-performance environments demanding maximum mechanical resilience.

Temperature Resistance and Thermal Shock

Borofloat glass offers excellent temperature resistance up to around 450degC and superior thermal shock resistance, making it ideal for applications involving rapid temperature changes. Quartz glass withstands much higher temperatures, exceeding 1,000degC, but with lower resistance to sudden thermal shocks due to its brittleness. For Your needs involving frequent temperature fluctuations, Borofloat glass provides more reliable durability.

Chemical Resistance Differences

Borofloat glass exhibits excellent chemical resistance against most acids, alkalis, and organic solvents, making it suitable for a variety of laboratory and industrial applications. Quartz glass, composed of pure silicon dioxide, offers superior resistance to hydrofluoric acid and high temperatures, outperforming borofloat in highly corrosive and extreme environments. The distinct chemical resistance profiles make borofloat glass ideal for general chemical exposure, whereas quartz glass is preferred for high-purity and aggressive chemical processing.

Applications in Industry and Science

Borofloat glass offers exceptional thermal shock resistance and chemical durability, making it ideal for laboratory glassware, pharmaceutical processing, and optical components in industrial automation. Quartz glass excels in high-purity applications requiring extreme temperature tolerance and UV transparency, such as semiconductor manufacturing, photolithography, and scientific instruments. Both materials are essential in scientific research and industrial processes, with Borofloat favored for mechanical robustness and quartz preferred for high-temperature and UV-specific applications.

Cost Efficiency and Availability

Borofloat glass offers superior cost efficiency due to its lower production expenses and widespread availability, making it a budget-friendly choice for many applications. Quartz glass, while more expensive, provides exceptional thermal and chemical resistance, but limited availability and higher manufacturing costs impact overall affordability. Your decision between the two depends on balancing budget constraints with performance requirements.

Choosing Between Borofloat and Quartz Glass

Choosing between Borofloat and quartz glass depends on your specific application's thermal and chemical requirements. Borofloat glass offers excellent thermal shock resistance and good chemical durability, making it ideal for labware and cookware. Quartz glass provides superior purity and higher temperature tolerance, suitable for high-precision optical components and semiconductor manufacturing.

borofloat glass vs quartz glass Infographic

libmatt.com

libmatt.com