Fused glass involves melting multiple layers of glass together at high temperatures, creating a smooth, solid piece with vibrant, blended colors and intricate designs, while slumped glass is heated just enough to soften and bend the glass into molds, maintaining its original layers and textures. When choosing between fused and slumped glass, your decision depends on whether you prefer a more seamless, artistic finish or a shaped, dimensional form for your project.

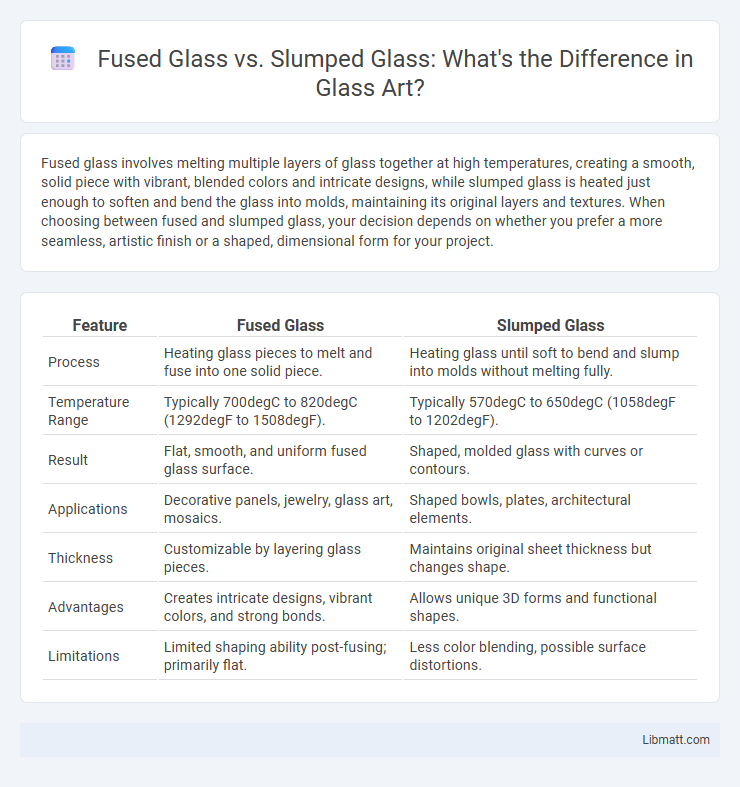

Table of Comparison

| Feature | Fused Glass | Slumped Glass |

|---|---|---|

| Process | Heating glass pieces to melt and fuse into one solid piece. | Heating glass until soft to bend and slump into molds without melting fully. |

| Temperature Range | Typically 700degC to 820degC (1292degF to 1508degF). | Typically 570degC to 650degC (1058degF to 1202degF). |

| Result | Flat, smooth, and uniform fused glass surface. | Shaped, molded glass with curves or contours. |

| Applications | Decorative panels, jewelry, glass art, mosaics. | Shaped bowls, plates, architectural elements. |

| Thickness | Customizable by layering glass pieces. | Maintains original sheet thickness but changes shape. |

| Advantages | Creates intricate designs, vibrant colors, and strong bonds. | Allows unique 3D forms and functional shapes. |

| Limitations | Limited shaping ability post-fusing; primarily flat. | Less color blending, possible surface distortions. |

Understanding Fused Glass: Definition and Techniques

Fused glass involves melting pieces of glass together at high temperatures, typically between 1,100degF and 1,500degF, to create a single solid piece with smooth, seamless surfaces. Techniques include tack fusing, where glass pieces partially melt and retain some texture, and full fusing, which results in a completely fused, flat surface. Unlike slumped glass, which is heated just enough to soften and conform to a mold's shape without full melting, fused glass achieves complete fusion through controlled heating cycles in a kiln.

What is Slumped Glass? Process and Applications

Slumped glass is formed by heating glass sheets in a kiln until they soften and bend over a mold, creating three-dimensional shapes without fully melting the glass. This process allows for precise shaping of glass for applications such as decorative bowls, plates, and architectural panels. Common in artisan crafts, slumped glass is valued for its smooth contours and structural integrity in functional art pieces.

Key Differences Between Fused and Slumped Glass

Fused glass involves heating glass pieces until they melt together into a single, smooth surface, creating vibrant, seamless art with strong structural integrity. Slumped glass is formed by heating glass over a mold just enough to soften and take its shape, producing curved or textured designs without full fusion. Understanding these key differences helps you choose the right technique for your project's desired texture, shape, and durability.

Materials and Tools Needed for Each Process

Fused glass requires high-quality glass sheets, a kiln capable of reaching temperatures between 1400degF and 1500degF, and compatibility between glass types to prevent cracking during the melting process. Slumped glass involves pre-cut glass pieces, molds often made from ceramic or steel, and a kiln set to a lower temperature range, typically between 1100degF and 1300degF, to soften rather than fully melt the glass. Your choice between these techniques depends on the specific materials and tools available, as fused glass demands precise thermal control for proper fusion, while slumped glass focuses on shaping softened glass over molds.

Artistic Possibilities with Fused Glass

Fused glass offers unparalleled artistic possibilities by allowing you to layer multiple glass pieces and colors in intricate patterns that fuse together during the kiln heating process, creating vibrant, seamless designs. Unlike slumped glass, which molds glass into shapes by softening it over a mold, fused glass maintains detailed patterns and complex color blending, making it ideal for detailed decorative art pieces. Artists can experiment with textures, inclusions, and varying degrees of transparency to achieve unique effects that are difficult to replicate with slumping techniques.

Design Flexibility in Slumped Glass Creations

Slumped glass offers exceptional design flexibility by allowing you to create complex three-dimensional shapes through controlled heating processes. Unlike fused glass, which primarily involves layering and bonding flat pieces, slumped glass can conform to molds for custom contours, making it ideal for artistic and functional applications like bowls, lampshades, and architectural elements. This versatility enables unique textures and forms that enhance the visual and tactile appeal of your glass creations.

Durability and Strength Comparison

Fused glass features higher durability and strength due to its process of melting glass layers into a single, solid piece at temperatures around 1400degF, resulting in enhanced structural integrity. Slumped glass, heated to lower temperatures (around 1200degF) to mold into shapes without fully fusing, tends to be more fragile and less resistant to impact or stress. Understanding these differences helps you choose the right glass type for projects requiring superior strength and longevity.

Cost Considerations: Fused vs Slumped Glass

Fused glass typically incurs higher material and labor costs due to the precision required in layering and the longer kiln firing times, making it more expensive than slumped glass. Slumped glass generally offers a more cost-effective option because it utilizes simpler techniques and shorter firing cycles, reducing energy consumption and production time. Choosing between fused and slumped glass depends on budget constraints and the desired intricacy of the finished piece.

Popular Uses in Art, Décor, and Architecture

Fused glass is popular in creating vibrant art pieces, decorative panels, and intricate jewelry due to its ability to combine multiple glass colors and textures seamlessly. Slumped glass is frequently used in architectural applications such as custom sinks, tabletops, and door inserts, where its curved shapes and structural form add both functionality and aesthetic appeal. Both techniques enhance interior decor by offering unique visual effects, with fused glass highlighting detailed designs and slumped glass emphasizing smooth, organic contours.

Choosing the Right Glass Technique for Your Project

Fused glass involves melting multiple glass layers at high temperatures to create a single, smooth piece with vivid color blends, ideal for intricate designs and jewelry. Slumped glass is heated just enough to soften and mold the glass over a form, perfect for creating curved shapes like bowls or plates with precise contours. Selecting between fused and slumped glass depends on the desired texture, form complexity, and functional purpose of your project.

Fused glass vs slumped glass Infographic

libmatt.com

libmatt.com