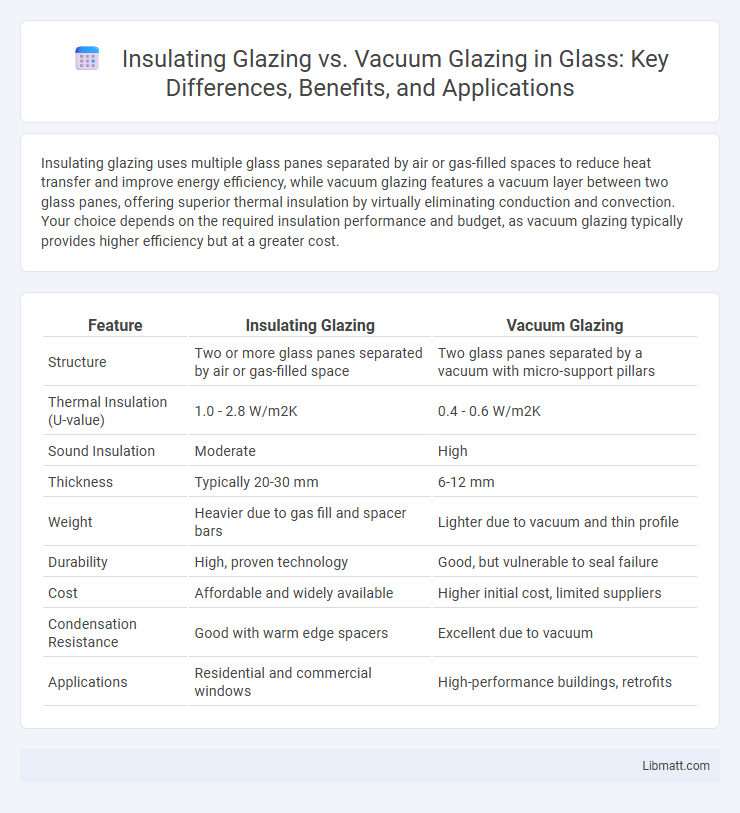

Insulating glazing uses multiple glass panes separated by air or gas-filled spaces to reduce heat transfer and improve energy efficiency, while vacuum glazing features a vacuum layer between two glass panes, offering superior thermal insulation by virtually eliminating conduction and convection. Your choice depends on the required insulation performance and budget, as vacuum glazing typically provides higher efficiency but at a greater cost.

Table of Comparison

| Feature | Insulating Glazing | Vacuum Glazing |

|---|---|---|

| Structure | Two or more glass panes separated by air or gas-filled space | Two glass panes separated by a vacuum with micro-support pillars |

| Thermal Insulation (U-value) | 1.0 - 2.8 W/m2K | 0.4 - 0.6 W/m2K |

| Sound Insulation | Moderate | High |

| Thickness | Typically 20-30 mm | 6-12 mm |

| Weight | Heavier due to gas fill and spacer bars | Lighter due to vacuum and thin profile |

| Durability | High, proven technology | Good, but vulnerable to seal failure |

| Cost | Affordable and widely available | Higher initial cost, limited suppliers |

| Condensation Resistance | Good with warm edge spacers | Excellent due to vacuum |

| Applications | Residential and commercial windows | High-performance buildings, retrofits |

Introduction to Insulating Glazing and Vacuum Glazing

Insulating glazing, commonly known as double or triple glazing, uses multiple glass panes separated by a gas-filled cavity to reduce heat transfer and improve energy efficiency. Vacuum glazing replaces the gas with a vacuum between two glass panes, significantly enhancing thermal insulation by minimizing convection and conduction. Your choice between these technologies depends on factors like insulation performance, space constraints, and cost.

How Insulating Glazing Works

Insulating glazing utilizes two or more glass panes separated by a spacer filled with air or inert gas, creating thermal insulation by reducing heat transfer through conduction and convection. The sealed air gap acts as an effective barrier, significantly minimizing heat loss and improving energy efficiency in windows. Low-emissivity coatings on the glass further enhance insulation by reflecting infrared radiation back into the interior space.

How Vacuum Glazing Works

Vacuum glazing works by creating a hermetically sealed space between two glass panes, with a vacuum in between to eliminate air and reduce heat transfer through conduction and convection. Tiny support pillars maintain the structural integrity of the panes, preventing them from collapsing inward under atmospheric pressure. Your energy efficiency is significantly improved compared to traditional insulating glazing due to the ultra-thin vacuum gap that minimizes thermal conductivity.

Thermal Performance Comparison

Vacuum glazing outperforms insulating glazing in thermal performance by significantly reducing heat transfer through a near-complete vacuum between glass panes, achieving U-values as low as 0.3 W/m2K compared to insulating glazing's typical 1.2 W/m2K. The absence of gas in vacuum glazing eliminates convection and conduction heat losses, providing superior insulation in thinner profiles, making it ideal for applications requiring enhanced energy efficiency without increased thickness. Insulating glazing relies on inert gas fills such as argon or krypton and spacer technologies that, while effective, cannot match the thermal barrier efficiency of vacuum glazing.

Acoustic Insulation: Which Performs Better?

Vacuum glazing offers superior acoustic insulation compared to traditional insulating glazing due to its minimal air gap, which significantly reduces sound transmission. The vacuum layer effectively blocks airborne noise, making it ideal for environments requiring enhanced soundproofing. Choosing vacuum glazing for your windows ensures better noise reduction and a quieter indoor atmosphere.

Energy Efficiency and Cost Savings

Insulating glazing improves energy efficiency by reducing heat transfer through multiple glass panes separated by air or gas, while vacuum glazing enhances this effect by eliminating air, creating a near-perfect thermal barrier with U-values as low as 0.4 W/m2K. Vacuum glazing typically offers greater energy savings over time, despite higher initial costs compared to traditional insulating glass units, making it a cost-effective solution for reducing heating and cooling expenses in your home. Investing in vacuum glazing maximizes insulation performance, leading to lower energy bills and increased long-term return on investment.

Durability and Lifespan

Vacuum glazing offers superior durability and a longer lifespan compared to traditional insulating glazing due to its robust construction and resistance to seal failure over time. Insulating glazing typically has a lifespan of 15-25 years, whereas vacuum glazing can last over 30 years when properly maintained. The enhanced durability of vacuum glazing results from its ability to maintain an ultra-thin vacuum layer that reduces thermal stress and minimizes condensation-related degradation.

Application Scenarios and Suitability

Insulating glazing is widely used in residential and commercial buildings for improving thermal performance and sound insulation, making it suitable for windows in temperate climates and energy-efficient construction. Vacuum glazing is ideal for high-performance applications requiring ultra-thin profiles and superior thermal insulation, such as heritage building renovations and skylights where space constraints and thermal efficiency are critical. Both technologies enhance energy savings, but vacuum glazing offers a higher insulation value, making it preferable in extreme climates or passive house designs.

Environmental Impact and Sustainability

Insulating glazing typically uses inert gases like argon or krypton between panes to reduce heat transfer, enhancing energy efficiency and lowering carbon emissions in buildings. Vacuum glazing achieves superior thermal insulation by creating a near-vacuum space between glass layers, minimizing conduction and convection, which significantly reduces heating and cooling energy demands. Both technologies contribute to sustainability by decreasing energy consumption, but vacuum glazing's thinner profile allows for lighter structures and less material use, offering additional environmental benefits.

Choosing the Right Glazing for Your Project

Insulating glazing, typically composed of two or more glass panes separated by a gas-filled space, offers excellent thermal insulation and soundproofing for residential and commercial buildings. Vacuum glazing uses a near-vacuum space between glass panes to drastically reduce heat transfer, providing superior energy efficiency in thinner profiles suitable for retrofit projects. Selecting the right glazing depends on factors such as project budget, desired thermal performance, space constraints, and long-term energy savings goals.

insulating glazing vs vacuum glazing Infographic

libmatt.com

libmatt.com