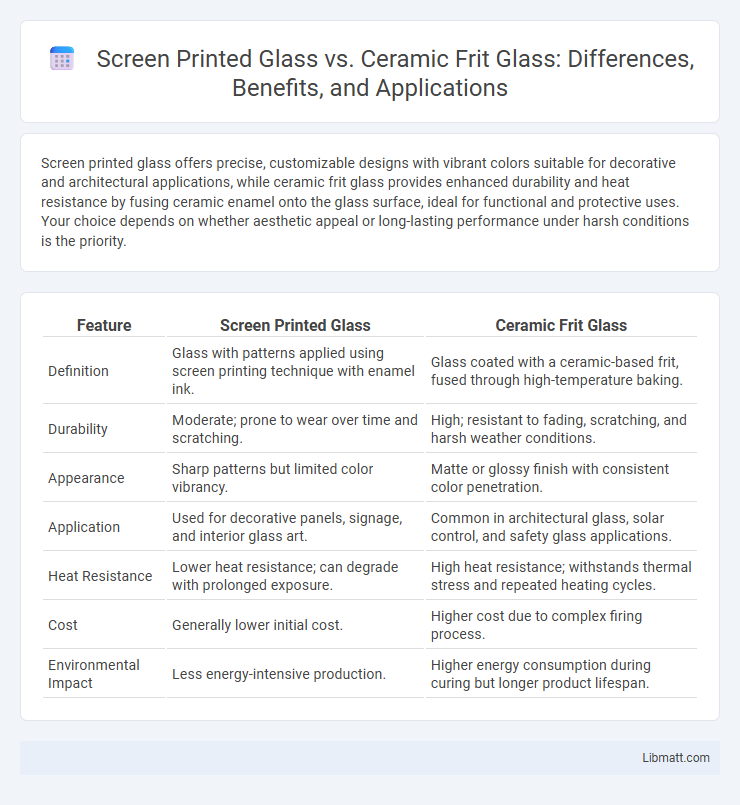

Screen printed glass offers precise, customizable designs with vibrant colors suitable for decorative and architectural applications, while ceramic frit glass provides enhanced durability and heat resistance by fusing ceramic enamel onto the glass surface, ideal for functional and protective uses. Your choice depends on whether aesthetic appeal or long-lasting performance under harsh conditions is the priority.

Table of Comparison

| Feature | Screen Printed Glass | Ceramic Frit Glass |

|---|---|---|

| Definition | Glass with patterns applied using screen printing technique with enamel ink. | Glass coated with a ceramic-based frit, fused through high-temperature baking. |

| Durability | Moderate; prone to wear over time and scratching. | High; resistant to fading, scratching, and harsh weather conditions. |

| Appearance | Sharp patterns but limited color vibrancy. | Matte or glossy finish with consistent color penetration. |

| Application | Used for decorative panels, signage, and interior glass art. | Common in architectural glass, solar control, and safety glass applications. |

| Heat Resistance | Lower heat resistance; can degrade with prolonged exposure. | High heat resistance; withstands thermal stress and repeated heating cycles. |

| Cost | Generally lower initial cost. | Higher cost due to complex firing process. |

| Environmental Impact | Less energy-intensive production. | Higher energy consumption during curing but longer product lifespan. |

Introduction to Decorative Glass Technologies

Screen printed glass utilizes durable inks applied through mesh screens to create vibrant, customizable patterns directly on the glass surface, ideal for architectural and interior design applications. Ceramic frit glass incorporates finely ground ceramic particles fused to the glass during the tempering process, offering enhanced durability, weather resistance, and UV stability for decorative and functional uses. Both technologies enable unique aesthetic customization while balancing performance requirements such as opacity, light transmission, and thermal resistance in modern decorative glass solutions.

What is Screen Printed Glass?

Screen printed glass involves applying ceramic or enamel inks through a mesh screen onto glass surfaces, creating precise patterns or designs that are fused during the tempering or baking process. This technique enhances the glass's aesthetic appeal and functional properties, such as UV protection and light diffusion, making it popular in architectural and decorative applications. Screen printed glass offers durability and customization, distinguishing it from ceramic frit glass, which uses powdered glass mixed with pigments before firing.

Understanding Ceramic Frit Glass

Ceramic frit glass is created by fusing finely ground ceramic particles onto glass, forming a durable, opaque coating that withstands high temperatures and UV exposure. This type of glass offers superior scratch resistance and longevity compared to screen printed glass, making it ideal for architectural applications where durability and aesthetic precision are crucial. Understanding ceramic frit glass helps you choose a material that maintains vibrant colors and structural integrity over time without fading or chipping.

Manufacturing Process Comparison

Screen printed glass involves applying ceramic-based inks through a mesh stencil to create patterns or designs, followed by curing at high temperatures to fuse the ink to the glass surface. Ceramic frit glass manufacturing entails coating the glass with powdered ceramic frit, which is then sintered during heat treatment to form a durable, opaque or translucent layer that bonds permanently to the glass. The primary difference lies in screen printing's precision for detailed graphics versus ceramic frit's robust, uniform coating suited for functional applications like solar control or privacy.

Durability and Performance Differences

Screen printed glass offers moderate durability with vibrant, customizable designs that withstand typical indoor use but may wear under harsh outdoor conditions. Ceramic frit glass features superior durability due to its baked-on ceramic frit coating, providing enhanced resistance to fading, scratching, and weathering, making it ideal for exterior applications. Your choice affects long-term performance, with ceramic frit glass delivering greater longevity and resilience in demanding environments.

Aesthetic Versatility and Design Options

Screen printed glass offers exceptional aesthetic versatility through vibrant colors and intricate patterns, allowing for custom designs that enhance architectural appeal. Ceramic frit glass provides durable, permanent finishes with a matte or textured appearance, ideal for subtle designs or privacy applications. Your choice depends on whether you prioritize bold, customizable visuals or long-lasting, understated elegance in design options.

Applications in Architecture and Interiors

Screen printed glass enhances architectural facades and interior partitions with customizable patterns and vibrant colors, providing excellent aesthetic versatility and solar control. Ceramic frit glass is preferred for its durability and weather resistance, ideal for exterior cladding and spandrel panels where long-lasting performance and opacity are required. Your choice depends on whether you prioritize decorative appeal or robust functionality in architectural and interior glass applications.

Cost Analysis: Screen Printed vs Ceramic Frit Glass

Screen printed glass typically offers lower upfront costs due to simpler manufacturing processes and faster production times compared to ceramic frit glass, which involves higher temperatures and more complex curing. However, ceramic frit glass provides better durability and resistance to weathering, potentially reducing long-term maintenance and replacement expenses. When analyzing cost, initial savings with screen printed glass must be balanced against the superior longevity and performance of ceramic frit glass in demanding environments.

Environmental and Safety Considerations

Screen printed glass typically uses organic inks that may release volatile organic compounds (VOCs) during production, requiring proper ventilation and handling to minimize environmental impact. Ceramic frit glass incorporates inorganic ceramic materials fused onto the glass surface at high temperatures, offering greater durability and resistance to weathering without harmful emissions. Both options should comply with regulations regarding emissions and worker safety, but ceramic frit glass generally provides an environmentally safer alternative with enhanced longevity and reduced maintenance needs.

Choosing the Right Glass for Your Project

Selecting between screen printed glass and ceramic frit glass depends on your project's specific needs, including durability, aesthetics, and application. Screen printed glass offers detailed designs and vibrant colors ideal for decorative purposes, while ceramic frit glass provides a more durable, weather-resistant surface suitable for exterior architectural use. Understanding your project's exposure and design requirements will help you choose the most effective glass type for lasting performance and visual appeal.

Screen printed glass vs ceramic frit glass Infographic

libmatt.com

libmatt.com