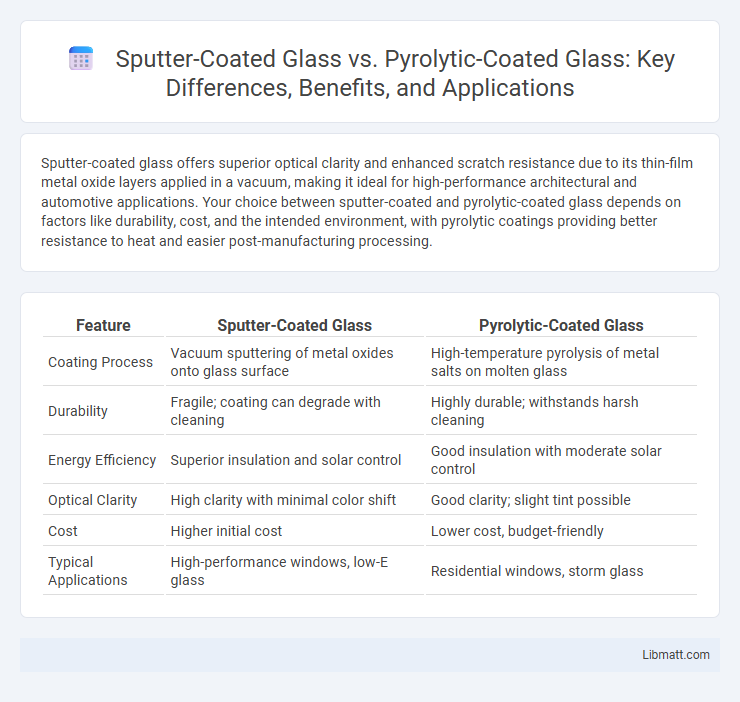

Sputter-coated glass offers superior optical clarity and enhanced scratch resistance due to its thin-film metal oxide layers applied in a vacuum, making it ideal for high-performance architectural and automotive applications. Your choice between sputter-coated and pyrolytic-coated glass depends on factors like durability, cost, and the intended environment, with pyrolytic coatings providing better resistance to heat and easier post-manufacturing processing.

Table of Comparison

| Feature | Sputter-Coated Glass | Pyrolytic-Coated Glass |

|---|---|---|

| Coating Process | Vacuum sputtering of metal oxides onto glass surface | High-temperature pyrolysis of metal salts on molten glass |

| Durability | Fragile; coating can degrade with cleaning | Highly durable; withstands harsh cleaning |

| Energy Efficiency | Superior insulation and solar control | Good insulation with moderate solar control |

| Optical Clarity | High clarity with minimal color shift | Good clarity; slight tint possible |

| Cost | Higher initial cost | Lower cost, budget-friendly |

| Typical Applications | High-performance windows, low-E glass | Residential windows, storm glass |

Introduction to Glass Coating Technologies

Sputter-coated glass utilizes a vacuum-based physical vapor deposition process to apply ultra-thin metal or metal oxide layers, enhancing thermal insulation and solar control properties. Pyrolytic-coated glass, or hard-coated glass, applies a high-temperature chemical vapor deposition during manufacturing, resulting in durable, scratch-resistant coatings ideal for energy-efficient windows. Your choice depends on the desired balance between cost, durability, and performance in solar heat rejection and visible light transmittance.

What is Sputter-Coated Glass?

Sputter-coated glass is created by depositing thin layers of metal or metal oxides onto glass surfaces using a vacuum-based physical vapor deposition process, enhancing properties such as solar control and thermal insulation. This coating technique allows precise control over layer thickness and composition, resulting in improved durability and optical clarity compared to other methods. Sputter-coated glass is commonly used in architectural and automotive applications for its superior energy efficiency and resistance to environmental factors.

What is Pyrolytic-Coated Glass?

Pyrolytic-coated glass, also known as hard-coated glass, is produced by applying a durable coating during the glass manufacturing process while the glass is still hot, resulting in excellent adhesion and resistance to scratching. This coating provides enhanced solar control and energy efficiency by reflecting infrared radiation while allowing visible light to pass through. Pyrolytic coatings are commonly used in windows and architectural applications due to their durability and ease of handling, making them suitable for both single and double glazing units.

Key Differences Between Sputter and Pyrolytic Coatings

Sputter-coated glass involves a vacuum process that deposits thin metal oxide layers, offering superior durability and precise control over coating thickness compared to pyrolytic-coated glass, which applies coatings during the glass manufacturing process for moderate durability. Sputter coatings excel in high-performance applications requiring enhanced solar control and reflectivity, while pyrolytic coatings provide cost-effective solutions with moderate anti-reflective and self-cleaning properties. Your choice depends on balancing performance needs with budget considerations and specific environmental conditions.

Performance Comparison: Energy Efficiency

Sputter-coated glass offers superior energy efficiency through its multiple thin metal oxide layers, enhancing solar control and thermal insulation by reflecting infrared radiation while allowing visible light. Pyrolytic-coated glass, with its integrated metal oxide during manufacturing, provides moderate energy savings by reducing heat transfer but generally has lower solar control performance compared to sputter coatings. Choosing the right glass for Your building impacts overall energy consumption, with sputter-coated glass often delivering better performance in reducing heating and cooling loads.

Durability and Maintenance Requirements

Sputter-coated glass offers enhanced durability due to its multi-layered metal oxides, making it more resistant to abrasion and environmental factors compared to pyrolytic-coated glass. Pyrolytic-coated glass features a hard, single-layer coating that bonds during the glass manufacturing process, providing moderate durability but easier maintenance since it can withstand on-site handling and cleaning without damage. Overall, sputter-coated glass requires careful maintenance to preserve its performance, while pyrolytic-coated glass is more forgiving and suitable for applications demanding simple upkeep.

Visual and Aesthetic Considerations

Sputter-coated glass offers superior clarity and a more neutral color appearance, making it ideal for applications where maintaining natural light and true colors is essential. Pyrolytic-coated glass tends to have a slight tint or reflective quality, which can influence the overall aesthetic by adding a subtle hue or glare. Your choice between these glass types will impact the visual ambiance and style of your space, with sputter-coated glass providing a cleaner, more transparent look.

Cost Analysis and Investment Value

Sputter-coated glass typically has a higher upfront cost due to its complex vacuum deposition process, making it a premium option for energy efficiency and aesthetic appeal. Pyrolytic-coated glass, while more affordable, offers durable performance with a lower initial investment, ideal for projects requiring cost-effective solutions. Your choice impacts long-term savings, with sputter-coated glass providing greater energy efficiency benefits that can enhance the overall investment value through reduced utility bills and improved property performance.

Best Applications for Each Glass Type

Sputter-coated glass excels in architectural applications requiring high thermal insulation and energy efficiency, such as commercial buildings with large window expanses, due to its durable multi-layer metal oxide coatings that reduce heat transfer. Pyrolytic-coated glass is best suited for single-step manufacturing processes and applications needing moderate solar control and scratch resistance, like automotive windows and facades, because its coating bonds at high temperatures during production. Understanding your project's specific performance needs helps determine whether sputter-coated or pyrolytic-coated glass offers the optimal balance of energy savings and durability.

Choosing the Right Coated Glass for Your Project

Sputter-coated glass offers superior energy efficiency and enhanced solar control due to its multi-layered thin film applied in a vacuum environment, making it ideal for high-performance architectural projects. Pyrolytic-coated glass, also known as hard-coated glass, provides durable, weather-resistant properties suitable for tempering and cost-effective applications requiring moderate insulation and scratch resistance. Selecting the right coated glass depends on balancing project requirements such as thermal insulation, solar heat gain coefficient, visible light transmittance, and budget constraints to optimize building performance and occupant comfort.

Sputter-coated glass vs pyrolytic-coated glass Infographic

libmatt.com

libmatt.com