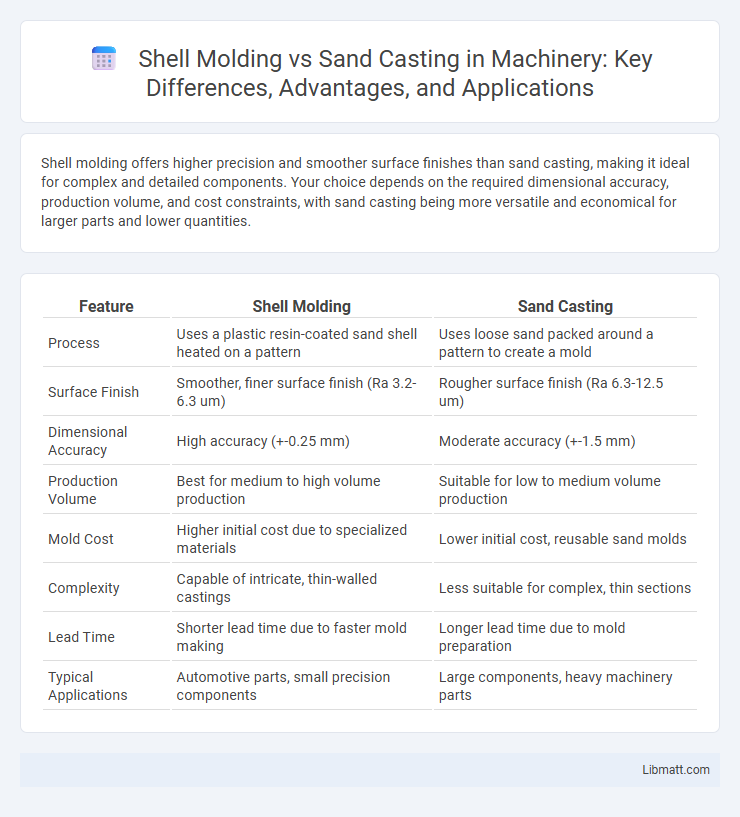

Shell molding offers higher precision and smoother surface finishes than sand casting, making it ideal for complex and detailed components. Your choice depends on the required dimensional accuracy, production volume, and cost constraints, with sand casting being more versatile and economical for larger parts and lower quantities.

Table of Comparison

| Feature | Shell Molding | Sand Casting |

|---|---|---|

| Process | Uses a plastic resin-coated sand shell heated on a pattern | Uses loose sand packed around a pattern to create a mold |

| Surface Finish | Smoother, finer surface finish (Ra 3.2-6.3 um) | Rougher surface finish (Ra 6.3-12.5 um) |

| Dimensional Accuracy | High accuracy (+-0.25 mm) | Moderate accuracy (+-1.5 mm) |

| Production Volume | Best for medium to high volume production | Suitable for low to medium volume production |

| Mold Cost | Higher initial cost due to specialized materials | Lower initial cost, reusable sand molds |

| Complexity | Capable of intricate, thin-walled castings | Less suitable for complex, thin sections |

| Lead Time | Shorter lead time due to faster mold making | Longer lead time due to mold preparation |

| Typical Applications | Automotive parts, small precision components | Large components, heavy machinery parts |

Introduction to Shell Molding and Sand Casting

Shell molding uses a resin-coated sand to form a thin, precise mold around a pattern, offering superior surface finish and dimensional accuracy compared to traditional sand casting. Sand casting relies on compacted sand to create molds, providing versatility and cost-effectiveness for large, complex parts but often resulting in rougher surfaces and less precision. Your choice between shell molding and sand casting depends on factors like component detail, production volume, and budget constraints.

Fundamental Process Overview

Shell molding involves creating a thin shell by curing a resin-covered sand mixture around a heated pattern, resulting in high precision and smooth surface finishes ideal for complex geometries. Sand casting uses a reusable sand mold formed around a pattern, offering versatility and cost-effectiveness for large and simple parts but typically requiring more post-processing. Understanding these fundamental differences helps you select the best casting method based on detail accuracy, production volume, and surface quality.

Materials Used in Each Process

Shell molding uses a fine sand mixed with thermosetting resin to create a hard shell mold, allowing for higher precision and smooth surface finishes. Sand casting employs coarser, naturally bonded sand combined with clay and water, providing flexibility in mold size and cost-effectiveness for larger parts. Your choice depends on the desired material properties and surface detail required for the final product.

Tooling and Pattern Requirements

Shell molding requires a precisely machined metal pattern coated with a resin-covered sand mixture, leading to higher initial tooling costs but superior surface finish and dimensional accuracy. Sand casting employs reusable wooden or metal patterns with low tooling expenses, offering flexibility for large and complex parts despite coarser surface quality. The choice between the two depends on production volume and complexity, with shell molding favored for high-precision, medium-volume runs and sand casting suitable for larger, less detailed components.

Surface Finish and Dimensional Accuracy

Shell molding offers superior surface finish and higher dimensional accuracy compared to sand casting due to its use of resin-coated sand, resulting in smoother surfaces and finer details. Sand casting typically produces rougher surfaces and less precise dimensions because of the granular nature of green sand molds. Choosing shell molding can enhance Your product's quality by reducing machining requirements and improving overall consistency.

Production Speed and Efficiency

Shell molding offers faster production speeds compared to sand casting due to its automated process and thin-walled mold design, which reduces cooling time significantly. The precision of shell molds enables higher efficiency by minimizing machining and finishing requirements, leading to shorter cycle times. Conversely, sand casting involves longer mold preparation and cooling durations, making it less efficient for high-volume production runs.

Cost Comparison: Initial and Ongoing

Shell molding offers higher initial costs due to specialized resin-coated sand and tooling but reduces ongoing expenses through faster production cycles and improved dimensional accuracy, minimizing machining and finishing. Sand casting involves lower startup costs with simpler equipment and materials but incurs higher ongoing costs from longer cycle times, increased labor, and more extensive post-processing. Overall, shell molding is cost-effective for high-volume production, while sand casting suits low-volume or larger parts with lower initial investment.

Typical Applications and Industries

Shell molding is widely used in automotive and aerospace industries for producing complex, high-precision components such as engine blocks and turbine blades, benefiting from its ability to deliver smooth surface finishes and tight tolerances. Sand casting is preferred in heavy machinery, construction, and agricultural sectors for manufacturing large, robust parts like pumps, valves, and engine housings due to its cost-effectiveness and versatility with various metals. Both processes serve essential roles in manufacturing, with shell molding excelling in smaller, intricate parts and sand casting dominating in large-scale, durable component production.

Environmental Impact and Waste Management

Shell molding produces less waste due to its higher precision and reduced scrap rates compared to sand casting, which generates significant amounts of used sand requiring disposal. The reusable resin-coated sand in shell molding minimizes environmental impact by lowering the volume of waste sent to landfills, while traditional sand casting often leads to increased raw material consumption and energy use through repeated sand reclamation. Emissions from shell molding are generally lower, as it uses less binder and generates fewer volatile organic compounds, contributing to more sustainable foundry practices.

Choosing the Right Casting Method

Choosing the right casting method depends on factors like production volume, precision, and surface finish requirements. Shell molding offers superior accuracy and smoother surfaces, making it ideal for complex, high-quality components, while sand casting is more cost-effective for large, low-precision parts and flexible for various metal types. Your decision should balance these attributes against budget constraints and intended application to optimize manufacturing efficiency.

Shell molding vs sand casting Infographic

libmatt.com

libmatt.com