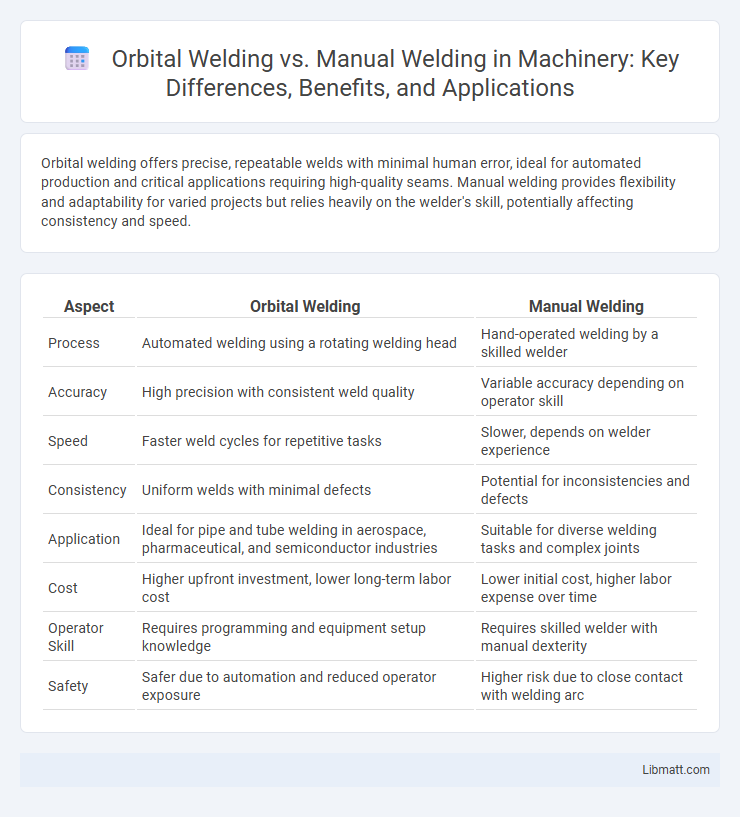

Orbital welding offers precise, repeatable welds with minimal human error, ideal for automated production and critical applications requiring high-quality seams. Manual welding provides flexibility and adaptability for varied projects but relies heavily on the welder's skill, potentially affecting consistency and speed.

Table of Comparison

| Aspect | Orbital Welding | Manual Welding |

|---|---|---|

| Process | Automated welding using a rotating welding head | Hand-operated welding by a skilled welder |

| Accuracy | High precision with consistent weld quality | Variable accuracy depending on operator skill |

| Speed | Faster weld cycles for repetitive tasks | Slower, depends on welder experience |

| Consistency | Uniform welds with minimal defects | Potential for inconsistencies and defects |

| Application | Ideal for pipe and tube welding in aerospace, pharmaceutical, and semiconductor industries | Suitable for diverse welding tasks and complex joints |

| Cost | Higher upfront investment, lower long-term labor cost | Lower initial cost, higher labor expense over time |

| Operator Skill | Requires programming and equipment setup knowledge | Requires skilled welder with manual dexterity |

| Safety | Safer due to automation and reduced operator exposure | Higher risk due to close contact with welding arc |

Introduction to Orbital Welding and Manual Welding

Orbital welding utilizes automated welding equipment to create precise, consistent welds around a pipe or tube, significantly reducing human error and improving weld quality. Manual welding relies on skilled operators to control the welding process, offering flexibility but with greater variability in weld consistency and quality. The choice between orbital and manual welding depends on factors such as application requirements, production volume, and the need for repeatability and precision.

Key Differences Between Orbital and Manual Welding

Orbital welding uses automated equipment to create precise, consistent welds around pipes or tubes, significantly reducing human error compared to manual welding, which relies on an operator's skill and steadiness. Orbital welding excels in producing high-quality welds in repetitive or complex applications such as aerospace, pharmaceuticals, and semiconductor industries, while manual welding offers flexibility for varied and one-off jobs requiring adaptability. Your choice between orbital and manual welding depends on factors like production volume, consistency requirements, and the complexity of the welding task.

Applications: Where Each Welding Method Excels

Orbital welding excels in industries requiring high precision and repeatability, such as aerospace, pharmaceuticals, and semiconductor manufacturing, where consistent, automated welds on tubing and pipelines minimize contamination and defects. Manual welding is preferred in construction, shipbuilding, and repair work, offering flexibility to weld complex, irregular joints and thicker materials where skilled human control adapts to varying conditions. Your choice between orbital and manual welding depends on the specific application demands, including required weld quality, production volume, and material complexity.

Precision and Quality: Orbital vs Manual Results

Orbital welding offers superior precision and consistent high-quality results due to automated, computer-controlled welding parameters, reducing human error and ensuring uniform welds. Manual welding depends heavily on the welder's skill and experience, which can lead to variability in weld quality and precision, especially in complex or repetitive tasks. Your projects benefit from orbital welding when exact, repeatable, and defect-free welds are critical, such as in aerospace, pharmaceuticals, or semiconductor industries.

Speed and Efficiency in Welding Processes

Orbital welding significantly improves speed and efficiency by automating the welding torch rotation around the workpiece, ensuring consistent, high-quality welds with minimal human error. Unlike manual welding, which relies heavily on operator skill and can result in slower weld times and inconsistent results, orbital welding delivers repeatable precision and faster cycle times in pipe and tube fabrication. This automated process reduces rework and downtime, enhancing overall productivity in high-volume manufacturing environments.

Safety Considerations for Both Methods

Orbital welding enhances safety by minimizing operator exposure to harmful fumes and sparks through automated, enclosed welding environments, reducing the risk of burns and inhalation hazards. Manual welding requires stringent use of personal protective equipment (PPE) such as gloves, helmets, and respirators to protect welders from intense heat, UV radiation, and toxic fumes. Both methods demand rigorous adherence to workspace ventilation standards and fire prevention protocols to ensure a safe welding environment.

Skill Requirements and Training Demands

Orbital welding requires highly specialized training and certification due to the precision and repeatability needed for automated control of the welding process, making it ideal for consistent, high-quality welds in critical industries like aerospace and pharmaceuticals. Manual welding demands extensive hands-on experience and skill development to manage variable conditions and maintain weld integrity, with proficiency gained over years of practice and continuous learning. The rigorous training for orbital welding focuses on equipment programming and monitoring, while manual welding training emphasizes manual dexterity, visual inspection, and adaptability to different welding scenarios.

Cost Comparison: Initial Investment and Operating Costs

Orbital welding requires a higher initial investment due to specialized equipment and automated systems, typically ranging from $50,000 to $200,000 depending on the complexity and size of the machinery. Manual welding has lower upfront costs but incurs higher operating expenses over time due to labor-intensive processes, increased material waste, and greater likelihood of rework. Over the long term, orbital welding reduces overall costs by improving precision, minimizing defects, and enhancing repeatability, leading to significant savings in labor and material compared to manual welding methods.

Maintenance and Equipment Longevity

Orbital welding systems require less frequent maintenance compared to manual welding due to their precision and automated control, which minimizes wear and tear on equipment. The consistency in weld quality reduces the need for rework and associated equipment stress, thereby extending the lifespan of welding tools and consumables. Automated orbital welding equipment often features built-in diagnostics and calibration alerts that help maintain optimal performance and prolong overall equipment longevity.

Choosing the Right Welding Method for Your Project

Orbital welding provides precise, repeatable, and high-quality welds ideal for projects requiring consistent results and minimal operator intervention. Manual welding offers greater flexibility and adaptability, making it suitable for complex geometries or situations where access is limited. You should evaluate project requirements, complexity, budget, and desired weld quality to select the optimal welding method.

Orbital welding vs manual welding Infographic

libmatt.com

libmatt.com