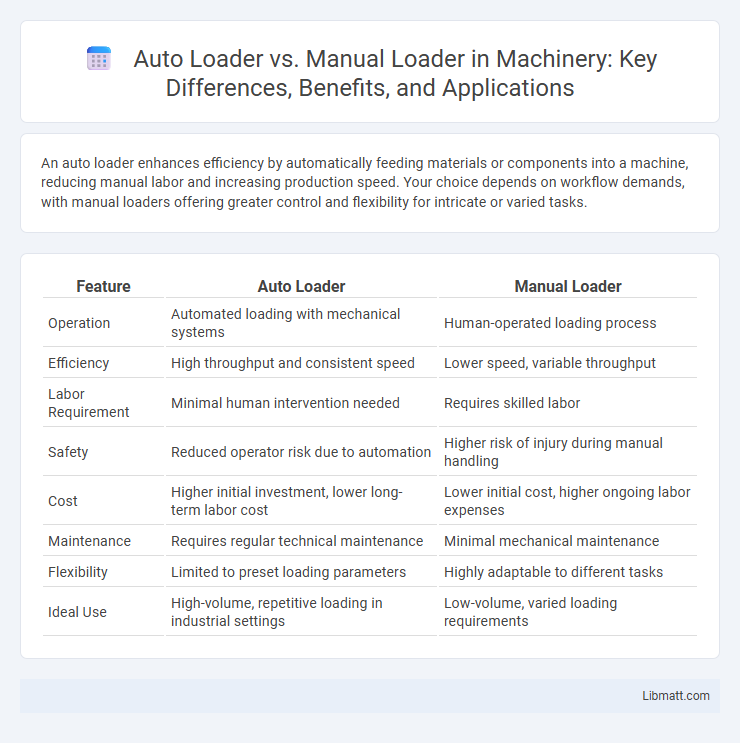

An auto loader enhances efficiency by automatically feeding materials or components into a machine, reducing manual labor and increasing production speed. Your choice depends on workflow demands, with manual loaders offering greater control and flexibility for intricate or varied tasks.

Table of Comparison

| Feature | Auto Loader | Manual Loader |

|---|---|---|

| Operation | Automated loading with mechanical systems | Human-operated loading process |

| Efficiency | High throughput and consistent speed | Lower speed, variable throughput |

| Labor Requirement | Minimal human intervention needed | Requires skilled labor |

| Safety | Reduced operator risk due to automation | Higher risk of injury during manual handling |

| Cost | Higher initial investment, lower long-term labor cost | Lower initial cost, higher ongoing labor expenses |

| Maintenance | Requires regular technical maintenance | Minimal mechanical maintenance |

| Flexibility | Limited to preset loading parameters | Highly adaptable to different tasks |

| Ideal Use | High-volume, repetitive loading in industrial settings | Low-volume, varied loading requirements |

Introduction to Auto Loaders and Manual Loaders

Auto loaders are automated mechanisms designed to load ammunition or materials efficiently, reducing human intervention and increasing operational speed. Manual loaders rely on human effort to perform loading tasks, often requiring physical strength and precision for safe handling. Comparing the two highlights differences in automation, efficiency, and ergonomics in various industrial and military applications.

Key Differences Between Auto and Manual Loaders

Auto loaders feature automated mechanisms that enable faster and more consistent material handling, significantly reducing manual labor and improving operational efficiency. Manual loaders rely on human intervention for loading tasks, offering greater control and flexibility but often resulting in slower processing speeds and increased risk of operator fatigue. The choice between auto and manual loaders hinges on factors such as production volume, precision requirements, and cost considerations, where auto loaders excel in high-volume environments and manual loaders suit smaller-scale or intricate operations.

Operational Efficiency: Auto vs Manual Loader

Auto loaders enhance operational efficiency by significantly reducing loading and unloading times through automated mechanisms, minimizing human errors and labor costs. Manual loaders rely heavily on human effort, resulting in slower cycle times and increased fatigue-related mistakes that can disrupt workflow. Automation in auto loaders supports consistent throughput and optimizes resource allocation, driving overall productivity improvements.

Safety Considerations in Loader Selection

Choosing between an auto loader and a manual loader significantly impacts safety outcomes on-site. Auto loaders reduce human error by automating material handling, minimizing operator exposure to hazards such as heavy lifting, pinch points, and repetitive strain injuries. Your decision should weigh the enhanced safety features of auto loaders against the control and situational awareness afforded by manual loaders in complex environments.

Maintenance Requirements for Each Loader Type

Auto loaders require less frequent maintenance due to automated operation, featuring self-diagnostic systems that reduce downtime and improve efficiency. Manual loaders demand regular inspections and more hands-on maintenance, including lubrication, tension adjustments, and operator checks to prevent wear and tear. Choosing between the two depends on the balance between initial investment and long-term maintenance costs.

Cost Comparison: Upfront and Long-Term

Auto loaders typically require a higher upfront investment due to advanced mechanical and electronic components but offer reduced labor costs and increased efficiency over time. Manual loaders have lower initial costs but can incur higher ongoing expenses related to labor, maintenance, and potential downtime. Evaluating total cost of ownership reveals that auto loaders often provide better long-term cost savings despite their initial premium.

Applications: When to Choose Auto or Manual

Auto loaders are ideal for high-volume industrial applications requiring consistent, rapid handling of materials such as in manufacturing, automotive assembly, and warehouse automation. Manual loaders are better suited for low-volume, specialized tasks where human judgment and flexibility are essential, including smaller workshops, custom fabrication, and maintenance operations. Selecting between auto and manual loaders depends on factors like production scale, precision requirements, and labor availability to optimize efficiency and cost-effectiveness.

Impact on Labor and Workforce

Auto loaders significantly reduce labor costs by minimizing the need for manual handling, enabling your workforce to focus on higher-skilled tasks and increasing overall productivity. Manual loaders require more physical labor, which can lead to fatigue, slower processing times, and higher risk of workplace injuries. Investing in auto loaders improves operational efficiency and enhances worker safety, making it a strategic choice for labor management.

Technological Advancements in Loading Systems

Technological advancements in loading systems have significantly improved the efficiency and safety of autoloaders compared to manual loaders. Autoloaders utilize automated robotics and sensors to precisely handle heavy materials, reducing human error and increasing loading speed. Your operations benefit from these innovations by minimizing downtime and enhancing workflow consistency in industrial and manufacturing environments.

Choosing the Right Loader for Your Needs

Selecting the appropriate loader depends on factors such as operational speed, ease of use, and volume capacity. Auto loaders offer automated functionality that enhances efficiency and reduces manual labor, ideal for high-throughput environments. Manual loaders provide greater control and flexibility at a lower cost, making them suitable for smaller-scale applications or tasks requiring precision.

Auto loader vs manual loader Infographic

libmatt.com

libmatt.com