Ductile iron offers superior toughness, flexibility, and impact resistance compared to cast iron, making it ideal for machinery components subjected to dynamic loads and stress. Choosing ductile iron enhances Your equipment's durability and performance in demanding industrial applications.

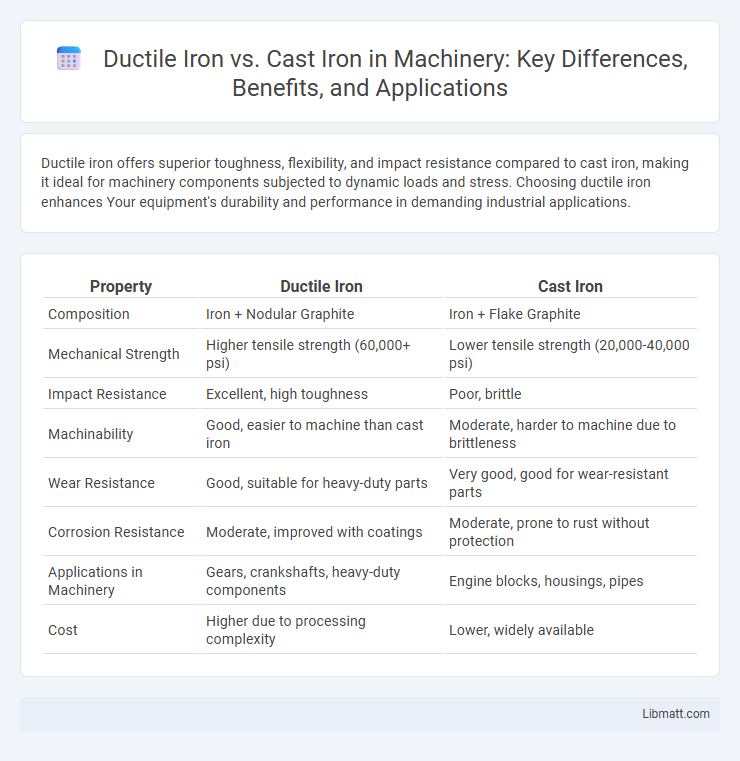

Table of Comparison

| Property | Ductile Iron | Cast Iron |

|---|---|---|

| Composition | Iron + Nodular Graphite | Iron + Flake Graphite |

| Mechanical Strength | Higher tensile strength (60,000+ psi) | Lower tensile strength (20,000-40,000 psi) |

| Impact Resistance | Excellent, high toughness | Poor, brittle |

| Machinability | Good, easier to machine than cast iron | Moderate, harder to machine due to brittleness |

| Wear Resistance | Good, suitable for heavy-duty parts | Very good, good for wear-resistant parts |

| Corrosion Resistance | Moderate, improved with coatings | Moderate, prone to rust without protection |

| Applications in Machinery | Gears, crankshafts, heavy-duty components | Engine blocks, housings, pipes |

| Cost | Higher due to processing complexity | Lower, widely available |

Introduction to Ductile Iron and Cast Iron

Ductile iron, also known as nodular or spheroidal graphite iron, offers superior tensile strength, impact resistance, and elongation compared to traditional cast iron, making it ideal for machinery components subject to dynamic loads. Cast iron, primarily grey cast iron, contains graphite flakes which provide excellent compressive strength and vibration damping but exhibit brittleness under tensile stress, limiting its use in high-stress mechanical parts. The choice between ductile iron and cast iron in machinery hinges on performance requirements such as fatigue resistance, machinability, and durability under operational conditions.

Chemical Composition Differences

Ductile iron contains higher amounts of magnesium and silicon, which modify the graphite microstructure into spherical nodules, enhancing ductility and impact resistance compared to cast iron's flake graphite structure. Cast iron primarily features carbon and silicon without significant magnesium content, resulting in a brittle and rigid material prone to fracture under stress. Your choice between ductile iron and cast iron for machinery applications should consider these chemical composition differences to balance strength, toughness, and machinability requirements.

Mechanical Strength Comparison

Ductile iron exhibits superior mechanical strength compared to cast iron, offering higher tensile strength typically ranging from 60,000 to 100,000 psi, whereas cast iron usually ranges between 20,000 and 60,000 psi. This enhanced strength in ductile iron results from its spheroidal graphite structure, which provides improved ductility and impact resistance, making it ideal for machinery components subjected to dynamic loads. Your equipment will benefit from ductile iron's ability to withstand greater mechanical stress without brittle failure, ensuring longer service life and reliability in demanding industrial applications.

Wear Resistance in Machinery Applications

Ductile iron offers superior wear resistance compared to cast iron in machinery applications due to its enhanced tensile strength and toughness, which reduce the risk of cracking under stress. The nodular graphite structure in ductile iron improves impact absorption and fatigue resistance, making it ideal for components such as gears, crankshafts, and heavy-duty machine parts. Cast iron, while harder and more brittle, tends to wear faster in dynamic loading conditions, limiting its use in high-impact or high-wear environments.

Ductility and Impact Resistance

Ductile iron offers superior ductility and impact resistance compared to cast iron, making it ideal for machinery components subjected to dynamic loads and shocks. Its microstructure, characterized by nodular graphite, enhances flexibility and reduces brittleness, preventing cracking in demanding applications. You can rely on ductile iron for parts requiring durability and toughness, whereas cast iron suits static or less impact-sensitive machinery parts.

Machinability and Fabrication Considerations

Ductile iron offers superior machinability compared to traditional cast iron due to its spherical graphite structure, which reduces tool wear and allows for faster machining speeds. Fabrication with ductile iron is favored in machinery usage because it provides enhanced toughness and ductility, enabling complex shapes and thinner sections without compromising strength. Your choice of material impacts production efficiency, as ductile iron typically requires less post-machining processing and provides better performance under dynamic loads.

Corrosion Resistance in Industrial Environments

Ductile iron exhibits superior corrosion resistance compared to cast iron in industrial environments due to its graphitic microstructure that reduces oxidation rates and enhances durability. Cast iron, with its brittle carbon flakes, is more prone to cracking and corrosion under harsh chemical exposure and fluctuating temperatures. This makes ductile iron the preferred choice for machinery components requiring long-term resistance to corrosive agents like moisture, acids, and industrial pollutants.

Cost Factors and Economic Impact

Ductile iron, while typically more expensive than cast iron due to its enhanced tensile strength and ductility, reduces maintenance costs and extends machinery lifespan, offering better long-term value in industrial applications. Cast iron, with lower upfront costs and excellent compressive strength, remains cost-effective for non-critical components where brittleness is less of a concern. Choosing between ductile and cast iron depends on balancing initial material costs against potential economic benefits from durability, performance, and decreased downtime in machinery usage.

Application Suitability in Machinery Components

Ductile iron offers superior impact resistance and fatigue strength, making it ideal for high-stress machinery components such as gears, crankshafts, and heavy-duty piping. Cast iron, with its excellent compressive strength and vibration damping properties, is preferred for machine bases, housings, and engine blocks where rigidity and wear resistance are critical. In machinery applications requiring a balance of toughness and machinability, ductile iron provides enhanced durability, while cast iron remains cost-effective for components subjected to less dynamic loading.

Conclusion: Choosing the Right Iron for Machinery

Ductile iron offers superior tensile strength, impact resistance, and fatigue durability compared to cast iron, making it ideal for high-stress machinery components like gears and crankshafts. Cast iron, with its excellent compressive strength and vibration damping properties, remains preferred for heavy-duty applications such as engine blocks and machine bases where rigidity is critical. Selecting the right iron depends on balancing mechanical performance requirements with cost-efficiency, ensuring optimal longevity and functionality in machinery operations.

Ductile iron vs cast iron (machinery usage) Infographic

libmatt.com

libmatt.com