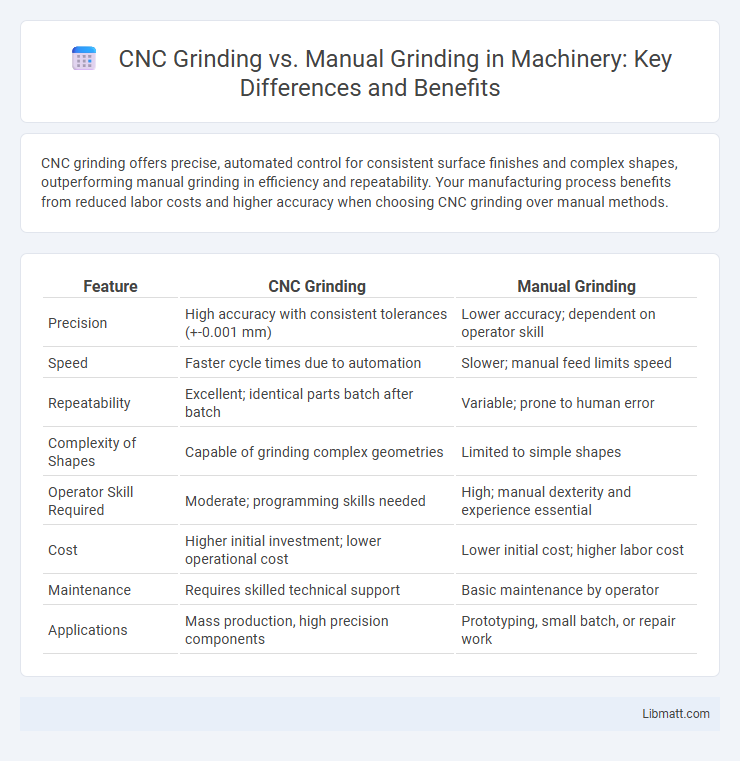

CNC grinding offers precise, automated control for consistent surface finishes and complex shapes, outperforming manual grinding in efficiency and repeatability. Your manufacturing process benefits from reduced labor costs and higher accuracy when choosing CNC grinding over manual methods.

Table of Comparison

| Feature | CNC Grinding | Manual Grinding |

|---|---|---|

| Precision | High accuracy with consistent tolerances (+-0.001 mm) | Lower accuracy; dependent on operator skill |

| Speed | Faster cycle times due to automation | Slower; manual feed limits speed |

| Repeatability | Excellent; identical parts batch after batch | Variable; prone to human error |

| Complexity of Shapes | Capable of grinding complex geometries | Limited to simple shapes |

| Operator Skill Required | Moderate; programming skills needed | High; manual dexterity and experience essential |

| Cost | Higher initial investment; lower operational cost | Lower initial cost; higher labor cost |

| Maintenance | Requires skilled technical support | Basic maintenance by operator |

| Applications | Mass production, high precision components | Prototyping, small batch, or repair work |

Introduction to CNC Grinding vs Manual Grinding

CNC grinding offers precise, automated control over grinding processes, resulting in consistently high-quality finishes and greater efficiency compared to manual grinding. Manual grinding relies heavily on operator skill, which can lead to variability in surface finish and longer production times. Your choice between CNC and manual grinding will impact accuracy, repeatability, and overall productivity in manufacturing applications.

Key Differences Between CNC and Manual Grinding

CNC grinding offers precise, automated control using computer numerical control technology, enabling consistent high-speed operations with minimal human error, while manual grinding relies on skilled operator techniques and direct control of the grinding tool. CNC machines provide repeatability and can handle complex, intricate shapes with superior surface finish, whereas manual grinding is more suited for custom, low-volume, or simple tasks requiring visual inspection during the process. The key differences include automation level, precision, consistency, speed, and operator involvement, with CNC grinding excelling in efficiency and accuracy in industrial applications.

Precision and Consistency in Grinding Methods

CNC grinding delivers superior precision with tolerances often within microns, ensuring consistent and repeatable results across complex geometries. Manual grinding relies heavily on the operator's skill, leading to variability and less predictable surface finishes. Automated CNC systems maintain uniform pressure and speed, minimizing human error and enhancing overall product quality.

Speed and Productivity Comparison

CNC grinding significantly outperforms manual grinding in speed and productivity, achieving high precision at automated rates that minimize cycle time. CNC machines can operate continuously with consistent accuracy, reducing setup times and human error, which leads to higher throughput in manufacturing environments. This automation enables faster processing of complex parts compared to the slower, labor-intensive manual grinding methods.

Complexity and Flexibility of Operations

CNC grinding offers superior complexity and flexibility compared to manual grinding by enabling precise control over intricate shapes and detailed surface finishes through programmable operations. Your production process benefits from consistent results and the ability to easily adjust parameters for diverse materials and geometries without extensive manual intervention. Manual grinding, while adaptable for simple or custom tasks, lacks the precision and repeatability needed for complex, high-volume manufacturing.

Operator Skill Requirements

CNC grinding requires operators to have advanced technical skills in programming, machine setup, and monitoring automated processes, ensuring high precision and repeatability. Manual grinding relies heavily on the craftsman's experience, dexterity, and visual acuity to maintain consistent quality and surface finish. While CNC reduces operator error and skill variability, skilled manual grinders are essential for delicate adjustments and custom jobs.

Cost Considerations: Initial Investment and Maintenance

CNC grinding requires a higher initial investment due to advanced machinery and software, but it offers lower long-term maintenance costs through automation and precision, reducing human error and material waste. Manual grinding involves lower upfront expenses but demands frequent maintenance and replacement of tools, increasing operational costs over time. Your choice depends on balancing immediate budget constraints with long-term efficiency and maintenance savings.

Applications Best Suited for CNC vs Manual Grinding

CNC grinding excels in high-precision applications such as aerospace components, medical devices, and automotive parts where tight tolerances and repeatability are critical. Manual grinding is better suited for custom, low-volume, or prototype work that requires skilled craftsmanship and flexibility in shape adjustments. CNC grinding offers enhanced efficiency and consistency, whereas manual grinding provides adaptability for complex or irregular surfaces.

Safety and Workplace Ergonomics

CNC grinding significantly enhances safety by minimizing direct human contact with sharp tools and rotating machinery, reducing the risk of injury compared to manual grinding. The automated nature of CNC machines also improves workplace ergonomics by reducing repetitive strain and physical exertion on your body, promoting better posture and less fatigue. Investing in CNC grinding technology creates a safer and more comfortable work environment while boosting productivity.

Future Trends in Grinding Technology

CNC grinding technology is rapidly advancing with the integration of AI-driven process optimization and adaptive control systems that enhance precision and reduce cycle times. Automated monitoring and real-time analytics enable predictive maintenance, significantly improving machine uptime compared to manual grinding. The shift toward Industry 4.0 and smart factories accelerates the adoption of CNC grinding, emphasizing repeatability, consistency, and scalability in manufacturing operations.

CNC grinding vs manual grinding Infographic

libmatt.com

libmatt.com