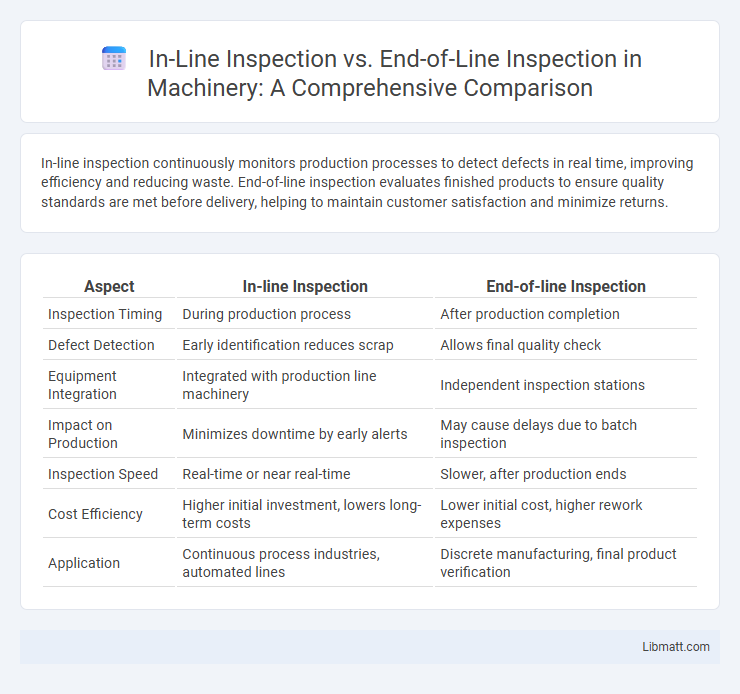

In-line inspection continuously monitors production processes to detect defects in real time, improving efficiency and reducing waste. End-of-line inspection evaluates finished products to ensure quality standards are met before delivery, helping to maintain customer satisfaction and minimize returns.

Table of Comparison

| Aspect | In-line Inspection | End-of-line Inspection |

|---|---|---|

| Inspection Timing | During production process | After production completion |

| Defect Detection | Early identification reduces scrap | Allows final quality check |

| Equipment Integration | Integrated with production line machinery | Independent inspection stations |

| Impact on Production | Minimizes downtime by early alerts | May cause delays due to batch inspection |

| Inspection Speed | Real-time or near real-time | Slower, after production ends |

| Cost Efficiency | Higher initial investment, lowers long-term costs | Lower initial cost, higher rework expenses |

| Application | Continuous process industries, automated lines | Discrete manufacturing, final product verification |

Introduction to In-Line and End-of-Line Inspection

In-line inspection integrates quality checks directly within the manufacturing process, enabling real-time detection and correction of defects to minimize production downtime. End-of-line inspection occurs after the completion of production, serving as a final verification step to ensure products meet specified quality standards before distribution. Both methods are critical in maintaining product integrity, with in-line inspection optimizing efficiency and end-of-line inspection providing conclusive quality assurance.

Defining In-Line Inspection

In-line inspection refers to the continuous monitoring and testing of products directly within the production process, enabling real-time quality control and immediate detection of defects. This method contrasts with end-of-line inspection, which occurs only after the manufacturing cycle is complete, often leading to delayed identification of issues. Your manufacturing efficiency and product reliability improve significantly with in-line inspection due to its integration within the operational workflow.

Understanding End-of-Line Inspection

End-of-line inspection is a critical quality control process performed after manufacturing to verify that products meet specified standards before distribution. This inspection method focuses on identifying defects, ensuring functionality, and confirming compliance with industry regulations by examining finished goods in their final state. It contrasts with in-line inspection by providing a comprehensive evaluation at the production end, reducing the risk of faulty products reaching customers.

Key Differences Between In-Line and End-of-Line Inspection

In-line inspection continuously monitors products during the manufacturing process, enabling early detection of defects and real-time quality control, while end-of-line inspection evaluates finished products before shipment to ensure overall quality compliance. Key differences include the timing of inspections, with in-line occurring during production and end-of-line occurring after completion, and the scope, where in-line focuses on immediate fault identification and process adjustment, whereas end-of-line emphasizes final product validation. Your choice between these methods impacts production efficiency, defect rates, and overall product reliability.

Advantages of In-Line Inspection in Manufacturing

In-line inspection in manufacturing offers real-time identification of defects, reducing waste and improving product quality by detecting issues during the production process. This method enhances production efficiency by enabling immediate corrective actions without halting the entire line, thereby minimizing downtime. You benefit from faster feedback loops and increased process control compared to traditional end-of-line inspection, which often detects defects only after production completion.

Benefits of End-of-Line Inspection Processes

End-of-line inspection processes enhance product quality by ensuring that all items meet strict standards before shipment, reducing the risk of defects reaching customers. These inspections facilitate comprehensive testing of the final product under real-world conditions, allowing for detection of issues that may not be apparent during in-line checks. Implementing end-of-line inspections also improves customer satisfaction and reduces costly returns or recalls by verifying compliance with regulatory requirements.

Common Applications for In-Line Inspection

In-line inspection is commonly applied in manufacturing processes where continuous quality monitoring is essential, such as electronics assembly, food packaging, and pharmaceutical production. This method detects defects in real-time, enabling immediate adjustments to maintain product standards and reduce waste. Your production efficiency and product consistency improve significantly by integrating in-line inspection systems compared to relying solely on end-of-line inspection.

Typical Uses of End-of-Line Inspection

End-of-line inspection is typically used for final quality control to ensure products meet specified standards before shipment. It is crucial for detecting surface defects, dimensional accuracy, and assembly completeness in manufacturing industries such as automotive, electronics, and pharmaceuticals. Your production line benefits from this step by reducing the risk of defective products reaching customers and maintaining brand reputation.

Choosing the Right Inspection Method: Key Factors

Selecting between in-line inspection and end-of-line inspection depends on accuracy requirements, production speed, and cost constraints. In-line inspection provides real-time defect detection during manufacturing, enhancing process control and reducing waste, making it suitable for high-volume production. End-of-line inspection offers comprehensive quality validation after production, ideal for critical products requiring thorough final assessment.

Future Trends in Industrial Inspection Technologies

Future trends in industrial inspection technologies emphasize the integration of artificial intelligence and machine learning with in-line inspection systems, enabling real-time defect detection and predictive maintenance that reduce downtime and increase product quality. End-of-line inspection technologies are evolving with advanced robotics and high-resolution imaging to provide comprehensive quality assessments before product shipment. Your manufacturing process will benefit from adopting these innovations, ensuring enhanced efficiency and compliance with increasingly stringent industry standards.

In-line inspection vs end-of-line inspection Infographic

libmatt.com

libmatt.com