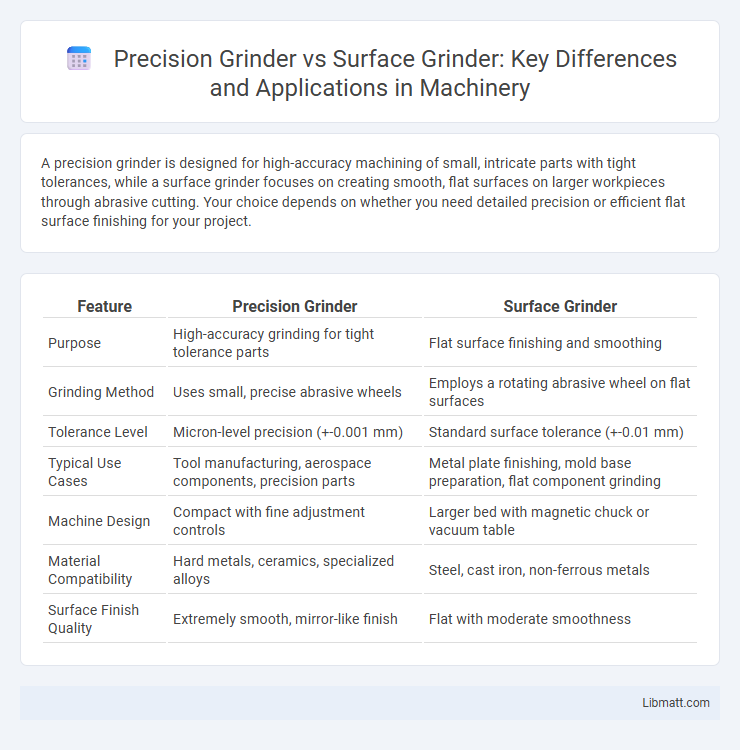

A precision grinder is designed for high-accuracy machining of small, intricate parts with tight tolerances, while a surface grinder focuses on creating smooth, flat surfaces on larger workpieces through abrasive cutting. Your choice depends on whether you need detailed precision or efficient flat surface finishing for your project.

Table of Comparison

| Feature | Precision Grinder | Surface Grinder |

|---|---|---|

| Purpose | High-accuracy grinding for tight tolerance parts | Flat surface finishing and smoothing |

| Grinding Method | Uses small, precise abrasive wheels | Employs a rotating abrasive wheel on flat surfaces |

| Tolerance Level | Micron-level precision (+-0.001 mm) | Standard surface tolerance (+-0.01 mm) |

| Typical Use Cases | Tool manufacturing, aerospace components, precision parts | Metal plate finishing, mold base preparation, flat component grinding |

| Machine Design | Compact with fine adjustment controls | Larger bed with magnetic chuck or vacuum table |

| Material Compatibility | Hard metals, ceramics, specialized alloys | Steel, cast iron, non-ferrous metals |

| Surface Finish Quality | Extremely smooth, mirror-like finish | Flat with moderate smoothness |

Introduction to Precision and Surface Grinders

Precision grinders deliver high-accuracy machining for intricate components in industries like aerospace and medical device manufacturing, ensuring tight tolerances and superior surface finishes. Surface grinders specialize in creating flat and smooth surfaces on workpieces using a rotating abrasive wheel, widely applied in metalworking and tool-making for consistent and precise surface quality. Understanding the distinct functions of these grinders helps you select the right equipment for specific grinding tasks to optimize your manufacturing processes.

Key Differences Between Precision and Surface Grinders

Precision grinders offer highly accurate, fine-tuned grinding suited for intricate components and tight tolerance requirements, using smaller grinding wheels and more precise controls. Surface grinders focus on producing flat, smooth surfaces on larger workpieces, typically employing larger grinding wheels and magnetic chucks for stability during operation. The key differences lie in application specificity, tolerance levels, and the scale of workpiece accommodation.

Applications of Precision Grinders

Precision grinders are essential in industries requiring tight tolerance and high accuracy, such as aerospace, medical device manufacturing, and tool making. They excel in producing complex shapes, intricate details, and fine finishes on hard materials like hardened steel and ceramics. Applications include grinding engine components, surgical instruments, and precision molds where exact dimensions and smooth surface finishes are critical.

Applications of Surface Grinders

Surface grinders are primarily used for producing smooth, flat surfaces on metal workpieces, making them ideal for applications requiring high precision and fine surface finishes such as tool and die making, automotive parts, and aerospace components. These machines excel in grinding flat surfaces, shoulders, slots, and intricate contours to tight tolerances. Your projects benefit from their ability to achieve exact dimensions and enhanced surface quality, critical in manufacturing industries.

Grinding Accuracy and Tolerance Comparison

Precision grinders offer superior grinding accuracy and tighter tolerances, often achieving measurements within a few microns due to advanced control systems and high-quality components. Surface grinders provide good accuracy for general applications but typically have wider tolerances, making them suitable for less demanding surface finishing tasks. Your choice depends on the required precision level, with precision grinders preferred for intricate, high-accuracy machining.

Material Compatibility: Precision vs Surface Grinding

Precision grinders are designed to handle a wide variety of materials including hardened steel, ceramics, and carbides, offering exceptional accuracy and surface finish. Surface grinders primarily work best with ferrous metals and softer materials but may struggle with complex or abrasive materials due to their less precise mechanisms. Your choice between a precision grinder and a surface grinder depends on the material compatibility needed for your specific machining requirements.

Machine Design and Operational Features

Precision grinders feature advanced spindle technology and rigid machine frames that ensure micron-level accuracy, making them ideal for intricate component finishing. Surface grinders utilize a stationary table and a rotating abrasive wheel, focusing on flat surface creation through uniform material removal. Your choice depends on the required tolerance, surface finish, and complexity of the workpiece geometry.

Cost and Maintenance Considerations

Precision grinders generally demand higher initial investment compared to surface grinders due to advanced technology and tighter tolerances. Maintenance costs for precision grinders can be elevated, requiring specialized parts and skilled technicians to ensure consistent accuracy. Surface grinders feature simpler mechanics, resulting in lower purchase prices and reduced routine maintenance expenses, making them cost-effective for basic grinding tasks.

Choosing the Right Grinder for Your Needs

Precision grinders excel in delivering highly accurate and intricate finishes, making them ideal for applications requiring tight tolerances and fine detail work. Surface grinders are better suited for creating smooth, flat surfaces on larger workpieces, offering efficient material removal and consistent surface quality. Your choice depends on whether your project demands exceptional precision or broader surface finishing, ensuring optimal results and productivity.

Summary: Which Grinder Suits Your Application?

Precision grinders offer high accuracy and fine tolerances, making them ideal for detailed machining of small, intricate parts requiring tight surface finishes. Surface grinders excel in producing flat, smooth surfaces on larger workpieces, suitable for applications needing consistent planar finishes with greater material removal. Choosing between the two depends on the specific requirements for dimensional precision, surface quality, and workpiece size.

Precision grinder vs surface grinder Infographic

libmatt.com

libmatt.com