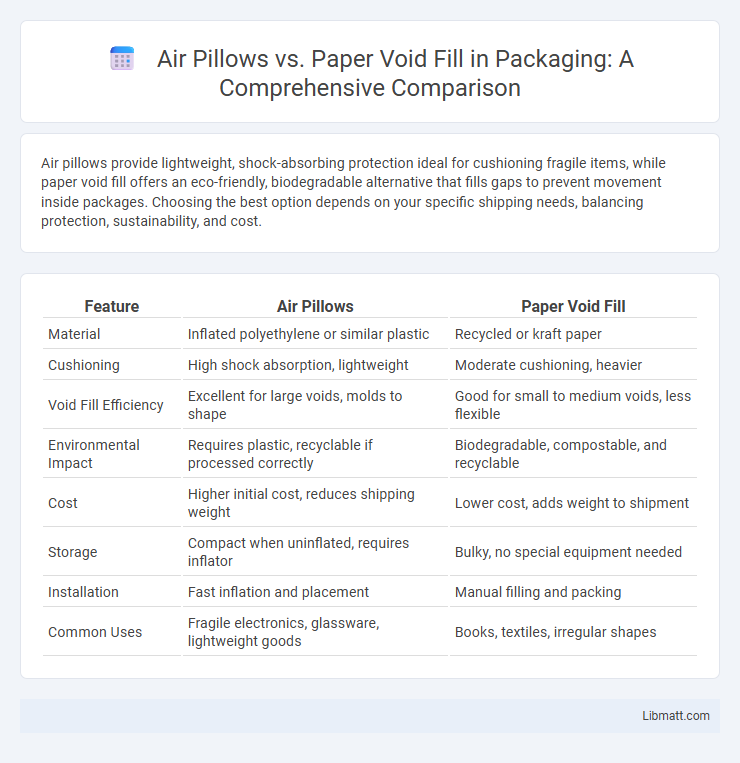

Air pillows provide lightweight, shock-absorbing protection ideal for cushioning fragile items, while paper void fill offers an eco-friendly, biodegradable alternative that fills gaps to prevent movement inside packages. Choosing the best option depends on your specific shipping needs, balancing protection, sustainability, and cost.

Table of Comparison

| Feature | Air Pillows | Paper Void Fill |

|---|---|---|

| Material | Inflated polyethylene or similar plastic | Recycled or kraft paper |

| Cushioning | High shock absorption, lightweight | Moderate cushioning, heavier |

| Void Fill Efficiency | Excellent for large voids, molds to shape | Good for small to medium voids, less flexible |

| Environmental Impact | Requires plastic, recyclable if processed correctly | Biodegradable, compostable, and recyclable |

| Cost | Higher initial cost, reduces shipping weight | Lower cost, adds weight to shipment |

| Storage | Compact when uninflated, requires inflator | Bulky, no special equipment needed |

| Installation | Fast inflation and placement | Manual filling and packing |

| Common Uses | Fragile electronics, glassware, lightweight goods | Books, textiles, irregular shapes |

Introduction to Air Pillows and Paper Void Fill

Air pillows are inflatable plastic cushions designed to fill voids in packaging, providing lightweight and flexible protection against impact during shipping. Paper void fill consists of crumpled or shredded paper materials used to secure items in place and prevent movement inside boxes. Both materials offer eco-friendly packaging solutions, with air pillows emphasizing recyclability and paper void fill highlighting biodegradability.

How Air Pillows Work

Air pillows provide lightweight cushioning by inflating plastic bags with air, creating a flexible barrier that absorbs shocks during shipping. These inflatable pillows conform easily to your product's shape, offering superior protection against impacts and vibrations. Unlike paper void fill, air pillows reduce bulk and are more effective at preventing movement inside packages.

How Paper Void Fill Functions

Paper void fill functions by providing a cushioning barrier that absorbs shocks and prevents movement within packaging, effectively protecting fragile items during transit. Its fibers create a natural, biodegradable buffer that conforms to product shapes, reducing the risk of damage through impact and vibration. Unlike air pillows, paper void fill offers eco-friendly waste options and can be easily recycled or composted after use.

Key Differences Between Air Pillows and Paper Void Fill

Air pillows provide lightweight cushioning with superior shock absorption, making them ideal for fragile items, while paper void fill offers eco-friendly, biodegradable padding that's excellent for filling gaps and preventing movement. Air pillows occupy less storage space and are quicker to deploy, whereas paper void fill supports recyclability and compostability, enhancing your sustainable packaging goals. Choosing between these options depends on your products' protection needs and environmental priorities.

Cost Comparison: Air Pillows vs Paper Void Fill

Air pillows offer a more cost-effective solution for bulk packaging due to their lightweight nature, reducing shipping expenses compared to heavier paper void fill. Paper void fill may incur higher costs because it requires larger storage space and can increase shipping weight, leading to elevated transportation fees. Your choice impacts overall packaging budgets, with air pillows often providing better value in both material and shipping costs.

Environmental Impact and Sustainability

Air pillows generate significantly less waste volume compared to paper void fill, reducing transportation emissions and landfill pressure, as they are made from recyclable, low-weight plastic film. In contrast, paper void fill derives from renewable resources and decomposes more quickly but often requires higher energy for production and disposal. Companies aiming for sustainability balance the carbon footprint of manufacturing air pillows with the biodegradability and recycling infrastructure of paper void fill options.

Protective Performance and Cushioning Effectiveness

Air pillows provide superior protective performance by absorbing impact through inflated, cushioned compartments that distribute pressure evenly, reducing product damage during transit. Paper void fill offers reliable cushioning by crumpling and conforming to product shapes, but may not provide consistent shock absorption compared to air pillows. Choosing the right material depends on Your product's fragility and shipping requirements, with air pillows excelling in lightweight yet high-impact protection.

Space and Storage Requirements

Air pillows require significantly less storage space compared to paper void fill, as they are compact and inflate only when needed, reducing bulk in your warehouse. Paper void fill demands larger storage areas due to its bulky rolls or sheets, which can consume valuable space and complicate inventory management. Choosing air pillows optimizes your packing area and minimizes storage overhead, enhancing operational efficiency.

Ease of Use and Packing Speed

Air pillows provide superior ease of use and packing speed due to their lightweight design and simple inflation process, allowing rapid cushioning without the need for complex assembly. Paper void fill requires manual adjustment and can slow down packing as it needs tearing, crumpling, or folding to fill spaces adequately. Your choice impacts efficiency, with air pillows streamlining operations for faster order fulfillment compared to the more labor-intensive paper void fill.

Choosing the Right Void Fill Solution for Your Business

Air pillows offer lightweight, cost-effective cushioning with superior shock absorption and minimal storage space, making them ideal for businesses prioritizing protection and efficiency. Paper void fill provides an eco-friendly, biodegradable option that excels for companies seeking sustainable packaging with good void filling and crushing resistance. Selecting the right void fill depends on product fragility, shipping volume, packaging sustainability goals, and cost-effectiveness within your supply chain strategy.

Air pillows vs paper void fill Infographic

libmatt.com

libmatt.com