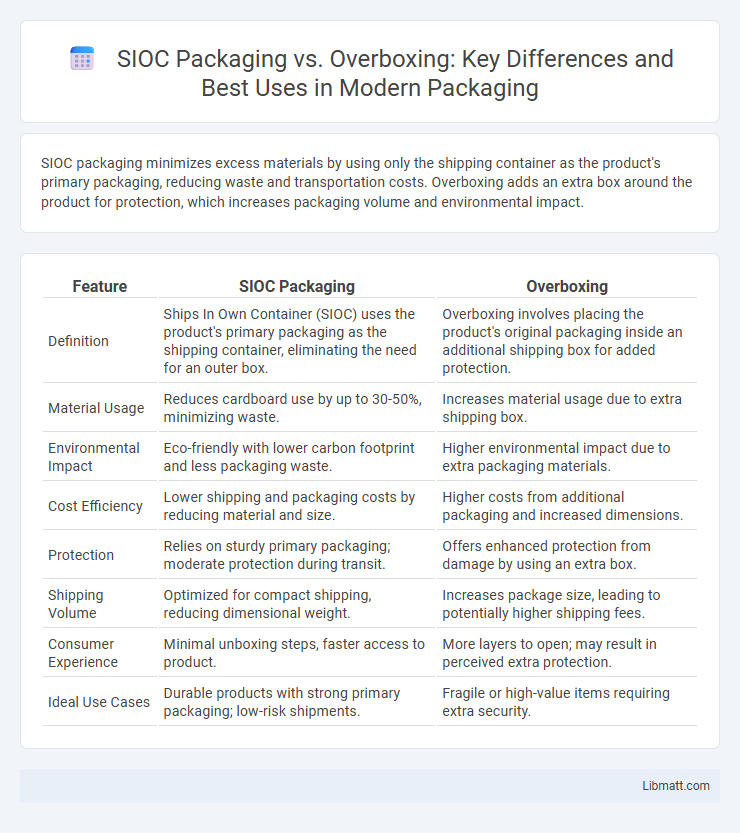

SIOC packaging minimizes excess materials by using only the shipping container as the product's primary packaging, reducing waste and transportation costs. Overboxing adds an extra box around the product for protection, which increases packaging volume and environmental impact.

Table of Comparison

| Feature | SIOC Packaging | Overboxing |

|---|---|---|

| Definition | Ships In Own Container (SIOC) uses the product's primary packaging as the shipping container, eliminating the need for an outer box. | Overboxing involves placing the product's original packaging inside an additional shipping box for added protection. |

| Material Usage | Reduces cardboard use by up to 30-50%, minimizing waste. | Increases material usage due to extra shipping box. |

| Environmental Impact | Eco-friendly with lower carbon footprint and less packaging waste. | Higher environmental impact due to extra packaging materials. |

| Cost Efficiency | Lower shipping and packaging costs by reducing material and size. | Higher costs from additional packaging and increased dimensions. |

| Protection | Relies on sturdy primary packaging; moderate protection during transit. | Offers enhanced protection from damage by using an extra box. |

| Shipping Volume | Optimized for compact shipping, reducing dimensional weight. | Increases package size, leading to potentially higher shipping fees. |

| Consumer Experience | Minimal unboxing steps, faster access to product. | More layers to open; may result in perceived extra protection. |

| Ideal Use Cases | Durable products with strong primary packaging; low-risk shipments. | Fragile or high-value items requiring extra security. |

What Is SIOC Packaging?

SIOC packaging, or Ships In Own Container, refers to a sustainable packaging solution designed to ship products safely without the need for an additional overbox or outer carton. This approach reduces packaging waste, lowers transportation costs, and enhances eco-efficiency by using sturdy, protective materials that secure the product within its original container. You benefit from streamlined logistics and improved sustainability by choosing SIOC packaging over traditional overboxing methods.

Understanding Overboxing in E-Commerce

Overboxing in e-commerce refers to the practice of using packaging that is significantly larger than the product itself, leading to increased shipping costs and environmental waste. SIOC (Ships In Own Container) packaging minimizes this issue by allowing products to be shipped in their retail-ready packaging without additional boxes, optimizing space and reducing material use. Implementing SIOC packaging enhances sustainability efforts and improves operational efficiency by lowering carbon footprints and shipping expenses.

Key Differences Between SIOC and Overboxing

SIOC packaging eliminates the need for secondary or overboxes by designing product packaging strong enough for direct shipping, while overboxing involves placing the primary product package inside a secondary box for protection. Key differences include environmental impact, where SIOC reduces waste by minimizing packaging materials, and cost efficiency, as SIOC lowers transportation and packaging expenses compared to the bulkier overboxing method. Furthermore, SIOC improves supply chain efficiency through lighter, compact packages, whereas overboxing adds extra weight and volume, increasing logistical complexity.

Advantages of SIOC Packaging

SIOC packaging reduces waste by eliminating the need for an outer shipping box, which lowers material costs and minimizes environmental impact. It enhances supply chain efficiency through easier handling and storage while providing superior product protection during transit. By choosing SIOC packaging, you streamline logistics and contribute to sustainable packaging practices.

Benefits of Overboxing for Businesses

Overboxing enhances product protection by providing an additional sturdy layer beyond the SIOC (Ships In Own Container) packaging, reducing damage during transit and minimizing returns. This method allows businesses to maintain brand integrity through customizable outer boxes that improve shelf appeal and customer experience. Your operational efficiency benefits from easier handling and stacking, leading to lower shipping costs and streamlined warehouse management.

Cost Comparison: SIOC vs. Overboxing

SIOC (Ships In Own Container) packaging significantly reduces costs by eliminating the need for secondary packaging like overboxes, cutting material expenses and lowering transportation costs due to reduced weight and volume. Overboxing incurs additional costs from extra materials, increased handling, and higher shipping fees caused by the larger package size. Companies adopting SIOC benefit from streamlined logistics and improved sustainability metrics, contributing to overall cost savings compared to traditional overboxing methods.

Environmental Impact: SIOC vs. Overboxing

SIOC packaging significantly reduces environmental impact by minimizing material usage and lowering carbon emissions during transportation compared to overboxing, which often involves excess packaging materials and increased waste. Choosing SIOC supports sustainable shipping practices by optimizing package dimensions and reducing volume, leading to fewer shipments and less fuel consumption. Your implementation of SIOC packaging helps decrease landfill contributions and promotes resource efficiency throughout the supply chain.

Customer Experience: SIOC versus Overboxing

SIOC packaging enhances customer experience by reducing waste and simplifying unboxing, leading to greater satisfaction and environmental consciousness. Overboxing often results in excess materials, increased shipping costs, and a cumbersome unboxing process that can frustrate customers. Brands prioritizing SIOC packaging benefit from streamlined logistics and a positive brand image driven by sustainability and convenience.

Choosing the Right Packaging Method

Choosing the right packaging method depends on product protection, cost efficiency, and sustainability goals. SIOC (Ships In Own Container) packaging reduces waste by allowing products to be shipped in their retail packaging without additional overboxing, minimizing material use and weight. Overboxing offers extra protection for fragile or high-value items but increases packaging costs and environmental impact due to added layers and materials.

Future Trends in E-Commerce Packaging

SIOC packaging, or Ships In Own Container, reduces the need for overboxing by using durable, protective materials that allow products to be shipped directly in their retail packaging. Future trends in e-commerce packaging emphasize sustainability, cost efficiency, and minimal waste, with SIOC solutions aligning with these priorities by lowering material usage and transportation footprint. You can expect increased adoption of advanced SIOC designs integrating protective inserts and smart technologies to enhance product security and customer experience while reducing environmental impact.

SIOC packaging vs overboxing Infographic

libmatt.com

libmatt.com